Drill and Tap Bit: Practical Comparison for Metalworking

Explore a detailed, evidence-based comparison of drill-and-tap bits versus separate drill + tap setups. Learn which approach delivers speed, precision, and cost efficiency for various metalworking tasks, with insights from Drill Bits Pro.

According to Drill Bits Pro, a drill and tap bit combines drilling and threading into one operation, delivering speed and consistency for light-to-moderate metalwork. It’s a great choice for repetitive holes in similar materials, but may sacrifice ultimate tolerance and tap quality on hard alloys. This article compares drill-and-tap bits with a traditional drill-plus-tap approach to help you pick the right tool for your project.

What is a drill and tap bit?

A drill and tap bit is a specialized tool that combines drilling and tapping into a single operation. The tip begins by drilling a pilot hole and then cutting the threads as the bit advances. This design is common in metalworking tasks where a consistent hole size and thread pitch are needed across many holes in similar parts. The tool comes in various thread sizes and pilot-hole diameters, so selecting the right size is crucial for reliability. Machine shops often rely on drill bits with built-in tapping capability to reduce setup time and to minimize the number of tool changes. According to Drill Bits Pro, the right drill-and-tap bit can significantly speed up repetitive fastening jobs, especially when you’re working with uniform materials like aluminum or mild steel.

In practice, you’ll typically see drill-and-tap bits offered in common thread standards (e.g., standard UNC/metric equivalents) and a range of pilot-hole diameters. When choosing, prioritize the actual hole diameter you need and the thread pitch your project requires. For DIY enthusiasts, a small starter set that covers common sizes can reduce decision fatigue and help you learn the tool’s behavior in your material of choice.

This section sets the stage for understanding how such bits behave in real-world conditions, as well as the trade-offs compared with using separate drilling and tapping steps. Drill Bits Pro’s analysis emphasizes that while single-pass tools boost productivity, they also demand tighter control of hole quality and material consistency to avoid thread defects.

Comparison

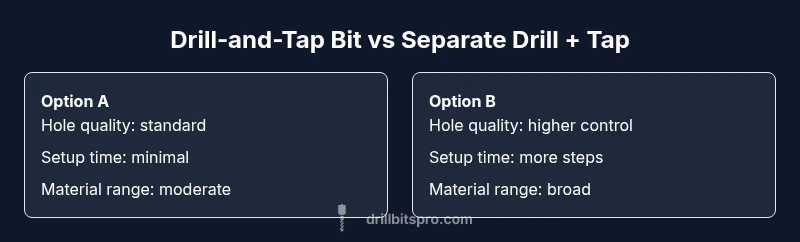

| Feature | Option A: Drill-and-Tap Bit | Option B: Separate Drill + Tap Set |

|---|---|---|

| Hole Quality | Excellent for standard materials with aligned hole and thread | Typically higher tolerance possible due to dedicated tools and greater control |

| Setup Time | Minimal; one tool handles drilling and tapping | Requires coordinating two tools and a separately drilled pilot hole |

| Tool Wear | Single tool bears combined cutting load | Two tools share wear, potentially extending overall life |

| Material Compatibility | Works well for aluminum, mild steel; limited in hard alloys | Broad compatibility, especially with varied materials and pitches |

| Best For | High-volume, quick-turn threading in uniform parts | Precision-focused projects or challenging materials |

| Cost | Lower upfront tool count; cost-effective for simple, repetitive jobs | Higher upfront due to two tools, but may reduce per-hole risk on tough materials |

What's Good

- Faster setup with fewer tool changes

- Ideal for repetitive holes in similar materials

- Reduces misalignment between drilling and threading steps

- Compact, beginner-friendly option

Negatives

- Less forgiving of hole-size deviations

- Tap quality can suffer on hard alloys or thick sections

- Limited thread-pitch options compared with separate tooling

- Not optimal for highly varied material types or finishes

Drill-and-tap bits excel in speed and simplicity for repetitive, light-to-moderate metalwork; separate drill + tap setups win where precision or material variety is critical.

Choose a drill-and-tap bit when you have uniform material, consistent hole sizes, and a need for quick turnaround. Opt for separate drill and tap tooling if you must maximize thread quality, handle hard materials, or deal with varied thread pitches across projects.

Got Questions?

What is a drill and tap bit?

A drill and tap bit is a single tool that drills a hole and cuts threads in one pass. It’s designed for repetitive, uniform parts where speed matters, but it requires precise hole sizes and suitable materials to avoid thread defects.

A drill-and-tap bit drills and threads in one go, ideal for quick, uniform holes in similar metals. Use it when speed matters and the material is predictable.

When should I choose drill-and-tap vs separate drill and tap?

Choose drill-and-tap for speed and simplicity in consistent jobs. If your project demands high thread quality, different materials, or variable thread pitches, a separate drill and tap often yields better results.

Pick drill-and-tap for speed on repeat jobs. For mixed materials or tight tolerances, go with separate drill and tap.

Can drill-and-tap bits be used on stainless steel?

Drill-and-tap bits can be used on stainless steel, but results depend on the alloy, thickness, and lubricant. Harder steels may require a dedicated tap and careful feed to avoid binding or thread damage.

Stainless can be tricky; use proper coolant and light feeds, and be prepared for more resistance.

What sizes do drill-and-tap bits come in?

Sizes vary by manufacturer, typically covering common metric and imperial thread pitches. Check the pilot-hole diameter and thread standard to ensure you’re matching your target hole and thread size.

They come in common sizes—check the packaging for the exact pilot hole and thread standard.

Are drill-and-tap bits suitable for aluminum?

Yes. Aluminum is generally forgiving, and drill-and-tap bits can perform well with proper lubrication and light feeds. For thicker aluminum or higher speed requirements, verify compatibility with the thread pitch.

Aluminum usually behaves nicely with drill-and-tap bits if you use the right feed and coolant.

How should I maintain drill-and-tap bits?

Keep bits clean, remove chips promptly, and use proper lubrication. Sharpening is limited; when dull, replace the bit. Store in a dry place to prevent corrosion and inspect for wear before reuse.

Clean and lubricate after use, store dry, and replace when dull.

Top Takeaways

- Choose drill-and-tap for speed in uniform jobs

- Prefer separate drill+tapping for high-precision or mixed materials

- Verify hole size and pitch compatibility before buying

- Maintain tools properly to maximize life and consistency

- Balance upfront tooling costs against expected production volume