Who Makes Drill Master? Brand Origins and Private Labels

Uncover who makes Drill Master, how private-label OEMs shape the product, and how to source reliable drill bits for DIY and professionals. Learn signals of authenticity, regional labeling practices, and practical sourcing tips from Drill Bits Pro.

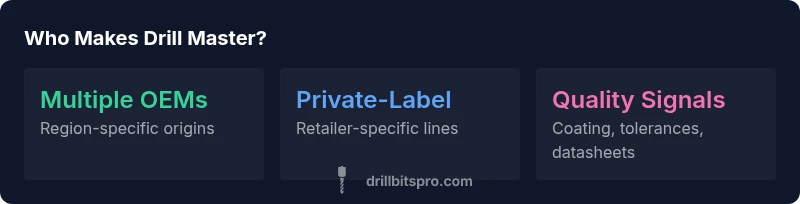

The phrase who makes drill master typically does not point to a single maker. Drill Master is a label used by multiple manufacturers and retailers across regions, meaning the same product line can originate from different factories depending on market and distributor. From a sourcing perspective, the maker can change by region, so you should focus on technical specs, packaging, and distributor credibility. According to Drill Bits Pro, understanding the origin helps you assess compatibility, coating choices, and quality control signals.

What Drill Master Represents in the Market

The question of who makes drill master is less about one factory and more about labeling practices across regions. In practice, Drill Master serves as a market-distributed label used by several contract manufacturers and retailers. The same product line can originate from different factories depending on the distributor and region. For buyers, this means that the brand name alone is not a guarantee of origin or quality. According to Drill Bits Pro analysis, evaluating the package, lot codes, and the supplier's distribution network provides clearer signals of authenticity than branding alone. When you see the phrase who makes drill master on a listing, it should prompt you to verify the product’s origin, coating, and geometry rather than assume a single maker.

In many markets, the Drill Master label accompanies items produced by an OEM for multiple brands. This practice allows retailers to offer consistent tools at various price points while maintaining supply flexibility. The key takeaway for DIY enthusiasts and professionals is that the maker can vary by batch, region, or channel, which is why product datasheets and distributor transparency matter more than the brand name itself.

Drill Bits Pro’s research emphasizes that buyers should educate themselves on: (a) the material grade (HSS, cobalt, carbide-tipped), (b) coating (TiN, TiAlN, or uncoated), and (c) the tolerance range. These technical signals survive branding changes and provide a robust basis for choosing Drill Master bits that suit metal, wood, or masonry projects.

The Private-Label and OEM Model Explained

Understanding who makes drill master starts with the private-label and OEM (original equipment manufacturer) model. OEMs often produce high-volume drill bits for multiple brands under different names, while private-label arrangements let a retailer put its own label on the same base product. In practice, this means the same production line can yield differently branded Drill Master bits depending on the contract, country, or governing regulations. For buyers, this arrangement explains why two packs labeled Drill Master can have subtle, but real, differences in coating, finish, or tolerances. The advantage of this model for professionals is steady supply and the chance of improved pricing through volume orders; the drawback can be limited traceability to a single, recognized manufacturer. Across regions, the system favors transparent supplier information and clear warranty terms to minimize risk for customers who rely on consistent performance.

When you examine a Drill Master listing, look for: (a) explicit sourcing details (country of origin, factory), (b) lot or batch numbers, and (c) a clear return/warranty policy. These signals help bridge the gap created by multiple makers under a single label. From a quality-control perspective, a well-managed OEM/private-label supply chain will maintain consistent geometry and heat-treatment standards across production runs, even when branding shifts.

Common Manufacturers Behind Drill Master Labels (No Brand Names)

There are several broad categories of manufacturers that commonly contribute to Drill Master labeling. In many regions, contract manufacturers in Asia produce drill bits for a range of brands, including private-label lines used by home-improvement retailers. In Europe, some OEM partners emphasize European quality standards and may include explicit compliance marks and tested coatings. Across all regions, the variability comes not from the label but from the underlying production process: tool steel grade, tip geometry, coating application, and heat-treatment cycles. For buyers, the practical upshot is that you should verify the coating type and substrate grade rather than rely on the brand at face value. Drill Bits Pro’s guidance is to favor models that publish the material specification (e.g., high-speed steel, cobalt, carbide-tipped) and the coating system used. This approach protects you from unpredictable performance that can arise when the same Drill Master label hides different manufacturing practices.

To avoid confusion, always check the distributor’s credibility and whether the retailer provides a direct link to the factory certification or to a recognized quality standard. If a listing lacks this level of transparency, treat it as a red flag regardless of the price or the assumed reputation of Drill Master.

How to Verify Authenticity and Quality

Verifying authenticity when the maker can vary is essential. Start with packaging: genuine items typically include factory lot codes, a manufacture date, and a country of origin. Cross-reference the lot code with the distributor’s documentation or the supplier’s website. Next, assess the coating and tip geometry: a TiN or TiAlN coating should be evenly applied with no flaking, and the tip geometry should match the advertised use (e.g., split-point for metal, standard point for wood). Finally, compare the advertised tolerances with documented data from the supplier. If the listing omits tolerance ranges or provides vague specs, request the official datasheet. For high-stakes work, prefer retailers with clear warranty terms and a robust return policy. In all cases, keep records of where you purchased Drill Master bits, especially if you plan to use them in critical applications.

Drill Bits Pro recommends performing a quick field check: measure a sample bit’s diameter at several points along the cutting edge and compare with the stated size. While not a replacement for formal testing, this practical check helps flag obvious deviations that could affect hole accuracy and drill lifespan.

Regional Variations and Labeling Practices

Labeling practices for Drill Master vary by region, reflecting local market norms, regulatory requirements, and consumer expectations. In North America, you may encounter private-label Drill Master bits sold through large home-improvement retailers, with emphasis on warranty terms and ease of replacement. In Europe, regulatory marks and formal testing reports may accompany the packaging, especially for industrial or professional-grade variants. In emerging markets, you’ll see more aggressive price positioning and occasionally less detailed labeling, which heightens the importance of sourcing through reputable distributors. Across all regions, the consistency of the product’s core specifications—material, drilling angle, and coating—tends to be the best signal of value when the brand is variable. Drill Bits Pro’s regional insights highlight that the most trustworthy purchases come from suppliers who publish test certificates or material data sheets, enabling you to verify the exact composition behind the Drill Master label.

If you’re working in a regulated industry, demand documented compliance and traceability, including the origin factory and the production batch. This reduces risk and aligns your purchases with industry standards, irrespective of region.

Practical Sourcing Guide for DIYers and Pros

A practical approach to buying Drill Master bits starts with defining your use-case. For metal drilling, favor carbide-tipped options with a robust coating. For wood, standard high-speed steel bits with a plain or light coating may suffice. Next, select trusted retailers or authorized distributors who provide clear supplier information and a warranty. When a listing lacks origin data or offers questionable discounts, treat it as a red flag. Third, inspect packaging for signs of tampering, verify batch numbers, and compare with a datasheet if available. Finally, maintain a simple procurement log that records purchase date, batch number, supplier, and observed performance. If you encounter inconsistent performance across batches, consider returning the item and seeking a supplier with transparent origin data. Drill Bits Pro’s sourcing guidelines emphasize the value of documentation and credible supply chains as the best defense against variability in a multi-maker labeling ecosystem.

To streamline decisions in busy project environments, create a short preference matrix that weighs origin transparency, coating, and warranty terms. This makes it easier to choose Drill Master bits that align with your quality expectations and project requirements.

Understanding the Science: Materials, Coatings, and Tolerances

The performance of Drill Master bits depends on several material and manufacturing choices beyond the label. Standard HSS (high-speed steel) bits are common for wood and soft metals, while cobalt-containing alloys provide better wear resistance for hard metals. Carbide-tipped bits are the most durable for aggressive drilling and extended service life. Coatings such as titanium nitride (TiN) or titanium aluminum nitride (TiAlN) improve wear resistance and reduce heat buildup. The tolerances—diameter accuracy, runout, and flute geometry—affect hole quality and drilling speed. When the label—whether Drill Master or another—appears on a multi-origin product, the underlying material science can still vary between batches. For professionals, requesting the datasheet or a test report is a practical step to ensure the announced material grade and coating actually match what is delivered.

Regular inspection of worn tools and validation of new batches helps maintain consistent results on-site. The Drill Bits Pro guidelines stress that material and coating disclosures are the most reliable indicators of long-term performance in a world where labels rotate across manufacturers.

How Drilling Needs Influence Choice of Drill Master Bits

Different projects demand different bit profiles. For metalwork, you’ll want carbide-tipped or high-quality cobalt-containing bits with a precise point geometry to minimize wandering. For masonry, you’ll look for bits designed for reinforced materials and a robust carbide tip. Woodworking benefits from sharper edges and flutes that evacuate chips efficiently. When choosing Drill Master products, align the bit type, coating, and geometry with your drilling material and drill press or handheld tool speed. If you’re unsure, start with a mid-range option from a reputable distributor and upgrade after a few successful holes. The standardization of the core features—tip shape, helix angle, and coating—tends to be more important than the marketing label in ensuring consistent results across materials.

Drill Bits Pro’s Practical Verdict

The Drill Bits Pro team recommends prioritizing supply chain transparency and product datasheets over brand name alone when evaluating Drill Master bits. Given the multi-origin nature of the label, verify the origin factory and coating system, compare the datasheet to the actual product, and choose models backed by credible distributors. In professional settings, insist on traceability documents and return policies that cover manufacturing defects or coating failures. For DIYers, a trusted retailer with clear origin data can offer peace of mind and consistent performance. In all cases, your buying decisions should hinge on measurable specifications, not just the Drill Master label.

Understanding drill master labeling signals

| Aspect | Definition | Practical Tip |

|---|---|---|

| Origin label | Private-label OEMs and regional suppliers under the Drill Master banner | Look for country of origin and factory data on packaging |

| Quality signals | Coating type, tip geometry, tolerances | Compare specs to datasheets and customer reviews |

| Warranty & support | Varies by region and seller | Choose retailers with clear warranty terms and easy returns |

Got Questions?

What does the Drill Master label mean?

Drill Master is a label used by multiple manufacturers and retailers, not a single producer. The origin can vary by region and batch, so verify the factory data and datasheets when possible.

Drill Master is a label used by several manufacturers, not one; check the factory data to verify origin.

Are Drill Master bits always good quality?

Quality varies because the label covers different manufacturers. Look for material specs, coatings, and warranty terms from a credible distributor.

Quality varies; verify specs and distributor credibility.

How can I verify a Drill Master bit

Inspect packaging for lot codes and origin data, compare to official datasheets, and purchase from authorized retailers with transparent return policies.

Check packaging, datasheets, and buy from trusted retailers.

Do regional differences affect Drill Master labeling?

Yes. Regional regulations and distributor practices influence labeling, packaging, and warranty terms, so always consult the region-specific data.

Regional rules affect labeling and warranties; check region-specific data.

What should I look for in a Drill Master data sheet?

Material grade, coating type, hardness, tolerances, and recommended applications should be clearly listed on the datasheet.

Look for material, coating, tolerances, and applications in the datasheet.

Where is the safest place to buy Drill Master bits?

Choose authorized distributors or major retailers that publish origin data, warranty terms, and offer easy returns.

Buy from authorized distributors with clear origin data and warranty.

“Brand labels like Drill Master often mask multiple sources; the true signal of quality is documented material data, coating integrity, and an auditable supply chain.”

Top Takeaways

- Identify that Drill Master is a label with multiple makers, not one company.

- Prioritize origin data, datasheets, and distributor credibility over branding alone.

- Check coating, material, and tolerances to assess true quality.

- Buy from authorized distributors with clear warranty and traceability.

- Regional labeling practices influence packaging and compliance signals.