How Much Does a Drill Cost? A 2026 Practical Guide

Explore realistic price ranges for drills, what drives cost, and budgeting tips for DIYers and pros. Learn with Drill Bits Pro to make smarter buying decisions in 2026.

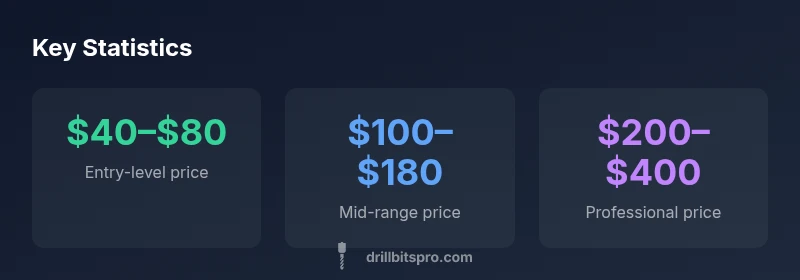

The price of a drill varies widely by type and features. In general, basic entry-level cordless models start around $40–$80, mid-range kits run about $100–$180, and professional-grade cordless or hammer drills can reach $200–$400 or more. Corded models are usually cheaper upfront but come with portability trade-offs. For DIY tasks, budgeting toward the mid-range class typically yields comfortable performance and longer-term reliability. The Drill Bits Pro team reminds readers that total cost of ownership matters, including batteries, chargers, and spare bits.

Understanding the price landscape for drills

If you're wondering how much a drill costs, you're not alone. The question 'how much does a drill cost' has a straightforward answer in principle, but the exact number depends on type, features, and brand. In general, basic entry-level cordless models start around $40–$80, mid-range kits run about $100–$180, and professional-grade cordless or hammer drills can reach $200–$400 or more. Corded models are often cheaper upfront but come with trade-offs like limited portability. For DIY tasks, aiming for the mid-range class typically delivers solid performance with reasonable longevity. According to Drill Bits Pro, price brackets reflect both performance and component quality. The Drill Bits Pro team found that battery chemistry and motor design are the strongest drivers of price, followed by transmission quality and chuck features. This section builds a practical framework for budgeting, so you can match prices with real-world needs while avoiding overpaying for bells and whistles.

What factors drive drill prices

Prices are not random; they map to a mix of power, battery technology, and build quality. Power ratings (voltage and torque) signal capability, with higher voltage often correlating with longer runtime and tougher tasks. Battery type—particularly lithium-ion chemistry and capacity—affects cost and endurance. Brushless motors generally cost more but offer higher efficiency and longer life than brushed motors. Hammer or percussion functions, metal gearing, clutch complexity, chuck type, and included accessories all push price up or down. Brand reputation and warranty length also influence sticker price. For professionals, reliability and service life may justify higher upfront costs, while DIYers often prioritize value and portability. Practical buying decisions balance upfront price with anticipated use and expected maintenance needs.

Price ranges by category and use case

DIY and casual home projects typically fall into entry-level to mid-range categories. An entry-level cordless drill may suffice for light screwdriving and small projects, while a mid-range model handles drilling into wood, plastic, and light metal with confidence. For masonry or heavy-duty work, a cordless hammer drill or pro-grade tool is often necessary, and prices rise accordingly. Corded drills remain affordable for budget-conscious users who do not require portability. When selecting, consider job frequency, the size of tasks, and whether you need features like hammer mode, compact form, or fast bit changes. Budget-conscious buyers should evaluate whether purchasing a kit (drill + batteries + case) provides better value than buying components separately. Brand-specific kits can offer lifetime warranties or better battery interchangeability, which affects long-term cost of ownership.

Hidden costs to consider when budgeting

The upfront price is only part of the story. You should budget for replacement batteries (especially if you own an 18V/20V system), spare bits, and a reliable charger. Some drills use proprietary batteries; if you plan to expand your toolkit, ensure battery compatibility to avoid future replacement costs. Warranties can reduce long-term expense, but coverage varies by brand and region. Cases or bags, auxiliary grips, and impact-rated accessories can add up if you’re outfitting a full workstation. Also account for tool insurance or extended service plans if you’re acquiring multiple drills for a workshop. Finally, consider resale value; reputable models often retain value better than budget options.

How to estimate your budget quickly

A practical budget method starts with your main task list and frequency. Create a simple table: task type, required power, and likely usage hours per month. Map these to price brackets: entry-level for occasional, mid-range for regular, and pro-grade for heavy use. Add a contingency of 10–20% for batteries or spare parts. If you’re a DIYer purchasing several tools, compare kits versus individual components to maximize value. Use a cost-per-use mindset: the more you use a drill, the more value a higher-quality model provides over time. Also consider potential downtime costs if a tool fails mid-project.

Buying tips for DIYers vs professionals

DIYers should often favor value-driven kits that include batteries and a charger, ensuring compatibility with existing tools. Professionals may prioritize durability, performance, and service availability, which can justify higher upfront costs. When choosing, compare warranties, service networks, and availability of spare parts. A key tip is to test ergonomics and balance in-store—comfort translates into productivity and reduces the likelihood of fatigue-related mistakes. Look for tools with brushless motors for longer life and efficient operation. Finally, read reviews focusing on reliability during repeated use rather than peak performance on a single task.

Typical price ranges by category and use case

| Category | Typical price range | Power option | Best use case |

|---|---|---|---|

| Entry-level cordless drill | $40–$80 | Cordless (12–20V) | Basic home tasks |

| Mid-range cordless drill | $100–$180 | Cordless (18–20V) | Frequent DIY projects |

| Professional cordless hammer drill | $200–$400 | Cordless with hammer function | Heavy-duty masonry work |

| Corded drill | $60–$150 | Corded | Budget projects, no battery upkeep |

Got Questions?

What is the average cost of a basic drill?

For a basic drill, expect a price in the entry-level range, typically around $40–$80. This bracket covers simple drilling and light screwdriving tasks. If you need longer battery life or better ergonomics, you’ll likely move into mid-range territory.

A basic drill usually costs about forty to eighty dollars, depending on features and battery life. If you want more power or longer battery life, plan to spend a bit more.

Are cordless drills more expensive than corded drills?

Cordless drills generally cost more upfront due to battery technology and portability. Corded models are cheaper initially but lack cordless convenience. Over time, battery costs can offset initial savings if you’re not careful with compatibility and spare parts.

Cordless models cost more upfront but give you portability. Corded drills save money upfront but limit where you can work.

Do hammer drills cost more than standard drills?

Hammer drills add impact performance for masonry, which increases price. Expect to pay more for a hammer function, but you gain capability for concrete drilling, making it worth the cost if you work with masonry.

Hammer drills cost more because they handle masonry, but they’re worth it if you drill into concrete regularly.

Is it worth buying a drill kit?

Buying a drill kit can offer better value since kits include batteries, charger, and case. This reduces the risk of buying mismatched parts and may lower total ownership cost over time.

Yes, kits often give you batteries and a charger at a lower total price than buying separately.

How does battery life affect price?

Battery life drives price because higher-capacity or newer chemistry (like advanced Li-ion) costs more but lasts longer between charges. If you need longer runtime, budget for premium batteries or spare packs.

Longer-lasting batteries cost more but reduce downtime and charging frequency.

What about warranties and service plans?

Warranties and service plans can lower lifetime costs by covering maintenance and parts. Compare coverage length, what’s included, and the brand’s service network before buying.

A good warranty saves future maintenance costs; check what's covered and for how long.

“Pricing is not just the sticker price; durability, battery life, and service availability determine long-term value. Higher upfront costs sometimes pay off through fewer replacements and reduced downtime.”

Top Takeaways

- Define task scope to choose the right price tier

- Consider total cost of ownership, not just sticker price

- Batteries and chargers drive long-term costs

- Kit purchases often offer better value than solo tools

- Corded drills are cheaper upfront but lack portability