What Drill Bit Do You Use for Metal: A Practical Guide

Learn which drill bits work best for metal, from HSS to cobalt and carbide, plus speeds, lubrication, and safety tips.

To drill metal, choose bits rated for metal use: high-speed steel (HSS) for aluminum and softer alloys, and cobalt or carbide-tipped bits for steel, stainless, and harder alloys. Use a sharp bit, a pilot hole, and cutting fluid. Run at slower speeds for steel and higher speeds for aluminum, and secure the work; a drill press yields the best results.

What drill bits are best for metal

According to Drill Bits Pro, choosing the right drill bit for metal starts with understanding the metal you’re working with and the bit’s material. For aluminum and soft alloys, standard high-speed steel (HSS) bits often provide good performance at modest speeds, with adequate lubrication and steady feeding. For tougher metals—steel, stainless, or high-strength alloys—invest in cobalt or carbide-tipped bits that resist heat and resist deformation under pressure. In practice, you’ll see a mix of bit types in any metalworking shop, but mastering the basics helps you avoid common mistakes like wandering holes, chipped edges, and premature bit wear.

In addition to material, consider flute design, point geometry, and bit diameter. A 135-degree split-point minimizes walking on hard metals, while a center-cutting or spur-style bit may be preferred for certain pilot-hole patterns. Coatings such as black oxide or titanium nitride can reduce friction and extend tool life, especially on harder metals. Always start with a sharp, properly sized bit and use the best lubrication you have available.

Metal hardness and bit choice

Metal hardness dictates how aggressively a bit will cut and how quickly it dulls. Softer metals like aluminum allow faster progress with HSS bits, provided you keep speeds reasonable and lubricate the cut. Harder metals—steel, stainless, and higher-strength alloys—generate more heat and wear; cobalt and carbide-tipped bits handle this load far better, though they come at a higher price and require careful handling due to brittleness. When selecting bits, match the bit material to the metal’s resistance to heat and deformation. If you’re unsure, start with a small pilot hole and verify that your lubricant and clamp setup prevent the bit from overheating or wandering.

A practical approach is to reserve HSS bits for aluminum and soft copper/brass, while keeping cobalt bits for steel and stainless. Carbide-tipped bits are excellent for repeated, high-precision work on hard metals, but they are less forgiving if misaligned or if the hole is not properly pilot-marked.

Speeds, feeds, and lubrication

Speed control is critical when drilling metal. Slower spindle speeds reduce heat buildup and prolong bit life, especially with steel and stainless. For aluminum and softer alloys, you can run at higher speeds, but you still need steady feed and cooling to manage chips and prevent galling. Lubrication is a must on steel and other hard metals; it lowers friction, reduces heat, and helps evacuate chips. A simple cutting oil or light machine oil can make a noticeable difference in tool longevity. If you’re using a cordless drill, enable a slow, steady feed and avoid high-torque bursts that can stall the bit or twist the shank.

In all cases, keep a clean path for chips to escape. Flush the hole periodically to prevent chip buildup, which can dull the edge and cause the bit to jam.

Pilot holes and center punch

A center punch is a small, pointed tool used to create a precise indent at the drilling start point. This indentation provides a tactile guide for the bit’s tip and reduces wandering in harder metals. For thick or hard sections, drill a shallow pilot hole with a smaller bit before advancing to the final diameter. Pilot holes reduce peak cutting forces, improve hole roundness, and help you achieve cleaner edges. Always verify alignment with a square or calipers to ensure accuracy before drilling.

When you’re ready, drill a tiny pilot hole first, then step up gradually to the final size. Deburr the pilot hole if necessary to prevent the larger bit from catching on the edge.

Drill bit materials in detail

High-speed steel (HSS) bits are versatile and affordable for aluminum and soft metals, and they work well at modest speeds with lubrication. Cobalt bits contain a higher percentage of cobalt, which improves heat resistance and edge retention for steel and stainless. Carbide-tipped bits are the most heat-resistant option and excel in demanding applications, but their brittleness means you must maintain precise alignment and secure workholding. For very hard metals, consider solid carbide bits, though these require rigid setups and careful handling to avoid breakage.

Bit geometry matters as well. A split-point design reduces walking, while a blunt chisel edge can worsen chip formation. For through-holes, a longer bit that maintains a consistent diameter helps minimize deflection and keeps the edge crisp.

Coatings and geometry

Coatings reduce friction and heat. Black oxide coatings provide some corrosion resistance and minor wear reduction, while titanium nitride (TiN) coatings offer higher wear resistance for repeated drilling in metal. When working with tough metals, consider bits with a positive rake angle and a sharp tip geometry to improve initial bite and reduce starting torque. If you’re drilling thicker stock, a step-bit approach or multiple passes with increasing diameters helps control heat and noise and yields cleaner edges. Always ensure the flute geometry aligns with chip evacuation needs for your material.

Choosing diameter and length

Hole diameter should match the final requirement, leaving a little margin for deburring. For tightly toleranced holes, select a bit slightly larger than the pilot hole’s diameter and increase cautiously to the final size. Shorter bits can be stiffer and less prone to bending, but longer bits reach deeper materials; ensure you have adequate clearance and an uncluttered work area. For through-holes in thick plates, choose long, sturdy bits and consider a pilot hole approach with step-down increments to reduce peak forces and prevent damage to the bit or workpiece.

Thick metal drilling strategy

Drilling thick metal often requires a staged approach. Start with a small pilot hole to reduce start-up forces, then move to a series of increasing diameters, stopping to clear chips and re-lubricate as needed. Use abundant lubrication on each step and maintain a straight, steady feed. If you’re working with deeper pockets or large-diameter holes, a drill press with a depth stop makes a noticeable difference in accuracy. Pay attention to chatter; a sacrificial backing material can help minimize burrs when starting from one side.

Common mistakes and how to fix them

Common mistakes include using dull bits, dry drilling, and attempting large holes with a small bit. Dull edges create heat and weld chips to the bit; replace or sharpen promptly. Dry drilling accelerates wear and can overheat steel; always lubricate. Misalignment causes wandering holes, so ensure your setup is secured and use a center punch. If the bit grabs or binds, back off slowly rather than forcing the bit. Finally, deburr edges to remove sharp remnants that can cause future cracks or injuries.

Safety and setup tips

Always wear eye protection, gloves, and hearing protection where appropriate. Secure the workpiece firmly with clamps or a vise, never hold by hand. Use a depth stop to prevent drilling through the far side unexpectedly. Keep cutting fluids away from moving parts and ensure the drill chuck is tightened properly. If using a cordless drill, keep a light touch and avoid high torque spikes that can twist or snap the bit. Practicing on a scrap piece helps build confidence before starting on the final workpiece.

Quick-start checklist

- Identify the metal type and choose the appropriate bit material (HSS for aluminum, cobalt or carbide for steel/stainless).

- Secure the workpiece and mark the drill start point with a center punch.

- Apply lubrication and start with a small pilot hole before final diameter.

- Use appropriate speeds and steady feeding; consider a drill press for best accuracy.

- Deburr and inspect the hole after drilling; store bits properly for longevity.

The Drill Bits Pro team emphasizes practicing safe setup and maintaining sharp tooling to achieve reliable results.

Tools & Materials

- Metal-rated drill bits (HSS, cobalt, carbide-tipped)(Choose based on metal type: HSS for aluminum/soft alloys; cobalt/carbide for steel/stainless)

- Cutting fluid or lubricant(Use oil or coolant for steel and hard metals to reduce heat)

- Center punch and marking tools(Center punch helps start the hole and keeps bit from wandering)

- Clamps or a vise(Secure workpiece to prevent movement during drilling)

- Pilot bit set(Helps create a guide hole before final diameter)

- Drill press or sturdy drill with depth stop(Improves accuracy and repeatability)

- Safety gear (eye protection, gloves)(Essential personal protective equipment)

- Backup scrap metal piece(Test cuts help dial in speed and feed before working on the final piece)

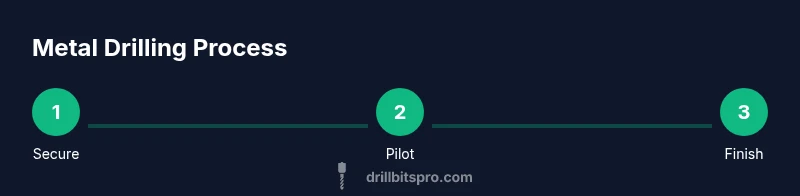

Steps

Estimated time: 45-75 minutes

- 1

Secure the workpiece

Clamp the metal piece firmly to a stable work surface and ensure there is clearance around the drill area. Verify that the piece will not shift during drilling and that the clamp won’t interfere with the bit’s path.

Tip: Use an edging scrap to protect the finish around the hole site. - 2

Choose the correct bit and diameter

Select a metal-rated bit appropriate for your metal type. Determine the final hole size and start with a smaller pilot hole if necessary.

Tip: When in doubt, start with a pilot hole and step up to the final diameter. - 3

Mark the start point

Use a center punch to create a small dimple at the drill point to prevent wandering. Check alignment with a square or ruler.

Tip: A sharp center punch creates a precise indentation with less drift. - 4

Lubricate and prep

Apply a light coat of cutting fluid or lubricant near the drilling site. Ensure the area stays clean and chips can escape freely.

Tip: Lubrication reduces heat and helps chips evacuate more easily. - 5

Begin with a pilot hole

Drill a shallow pilot hole using a small bit to guide the final bit. Maintain steady, light pressure to avoid grabbing.

Tip: Pilot holes reduce starting torque and improve accuracy. - 6

Progress to final diameter

Switch to the final bit size and drill slowly, applying consistent feed pressure. Stop occasionally to withdraw the bit and clear chips.

Tip: Maintain a straight path; slight wobble creates crooked holes. - 7

Control heat and chips

Continue cutting with lubrication and chip evacuation. If the bit dulls quickly, pause and inspect the edge; resharpen or change bits as needed.

Tip: Clear chips every few millimeters to maintain a clean cut. - 8

Finish and deburr

Withdraw the bit while still turning to avoid burr formation. Deburr the hole edges with a deburring tool or fine file.

Tip: A clean edge reduces stress risers that can crack nearby material. - 9

Inspect the hole

Check hole diameter, straightness, and finish. If needed, ream or enlarge slightly for a precise fit.

Tip: Measure hole diameter with calipers for accuracy. - 10

Cool-down and cleanup

Clean the work area, inspect tooling for wear, and wipe down bits before storage. Reapply lubrication if you’ll be cutting again soon.

Tip: Store bits in protective cases to prevent dulling and damage. - 11

Document settings

Record the metal type, bit size, lubrication used, and final hole diameter for future tasks. Documentation helps reproduce results.

Tip: Keep a small notebook or digital note for reference. - 12

Store and maintain tooling

Clean and dry bits after use, sharpen or replace dull bits, and keep the drill bits organized for next time.

Tip: Regular sharpening extends bit life and improves performance.

Got Questions?

What drill bit should I use for metal?

For aluminum and soft metals, use HSS bits. For steel or stainless, opt for cobalt or carbide-tipped bits. Always lubricate, use a pilot hole, and secure the workpiece.

Use HSS for aluminum and soft metals; cobalt or carbide-tipped bits for steel or stainless. Lubricate, pilot, and secure your work.

Can I drill stainless steel with regular drill bits?

Regular wood or low-grade steel bits wear quickly on stainless steel. Use cobalt or carbide-tipped bits designed for metal, with lubrication and slow speeds.

Regular bits wear out quickly on stainless. Use cobalt or carbide-tipped bits with lubrication and slow speeds.

Do I need a center punch?

Center punching creates a precise starting point and reduces wandering. It’s especially important on hard metals where the bit can drift.

Yes, center punching helps start the hole accurately and prevents wandering.

Should I use a drill press or a handheld drill?

A drill press provides the most repeatable results, maintaining straight holes and consistent depth. A stable handheld drill can work for small, simple holes with proper clamps.

A drill press is best for accuracy; a handheld drill can work with solid clamping for simple holes.

What speeds should I use for drilling metal?

Use slower speeds for steel and harder metals, and slightly higher speeds for aluminum. Always rely on lubrication to keep temperatures down and extend bit life.

Drill slowly for steel, a bit faster for aluminum, and lubricate well to keep surfaces cool.

How do I avoid burrs after drilling?

Deburr the hole with a file or deburring tool, and clean chips away before finishing. Deburring removes sharp edges and reduces stress risers.

Deburr the hole edges to remove sharp edges and improve fit.

Watch Video

Top Takeaways

- Match bit material to metal hardness.

- Use pilot holes and lubrication for clean cuts.

- Secure the workpiece before drilling.

- Choose the right speed to control heat.

- Deburr and inspect holes for quality.