Oil Well Drilling Costs: Onshore vs Offshore Averages

Learn the true cost to drill an oil well, including onshore vs offshore ranges, major cost drivers, and practical budgeting steps to prepare a realistic project plan.

Oil well drilling typically costs between $1 million and $5 million for a standard onshore project, with offshore wells often reaching tens or hundreds of millions depending on depth and conditions. According to Drill Bits Pro, site-specific factors—rig rates, mud programs, cementing, and completion needs—drive the final price, so a detailed, location-aware estimate is essential before committing to drilling.

The Baseline: What Drives the Cost to Drill an Oil Well

Understanding how much does it cost to drill an oil well begins with the baseline categories that drive every project: rig hire, drilling fluids, casing and cementing, well control equipment, and final completion. In practice, the final price is not a single number but a spectrum: a standard onshore well can range widely due to depth, geology, and logistics. This section breaks down each major driver and how it translates into your bottom line. According to Drill Bits Pro, the most influential factors are rig rates, crew size, mud programs, and completion scope.

Cost Drivers: Rig Type, Fuel, and Consumables

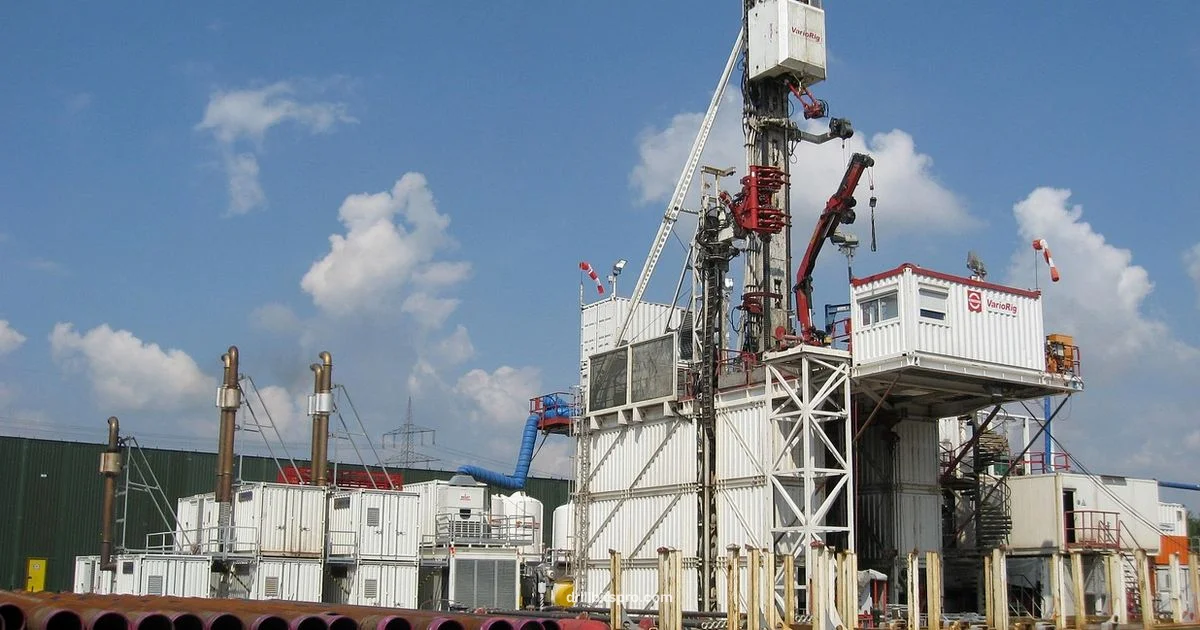

The primary cost driver is the rig and crew. Onshore rigs are comparatively compact and cheaper to mobilize, while offshore rigs—semis, drillships, or tender-assisted rigs—carry higher mobilization and day-rate costs. Fuel, lubricants, and drilling fluids add a sizable recurring cost, with mud programs and polymer additives influencing performance and price. Consumables such as drill pipe, bits, casing, and cementing materials must be accounted for in the bottom line. Another major factor is crew size and skill level; more complex geology or high-pressure formations require larger teams and more specialized personnel, which increases labor costs.

Onshore vs Offshore: Cost Divergence

Onshore projects typically feature lower capital intensity but can still drift due to terrain, access, and regulatory requirements. Offshore projects incur substantial upfront mobilization, platform or vessel deployment, and safety systems; deepwater projects may require multiple rigs and advanced subsea infrastructure, driving costs into the tens or hundreds of millions. When evaluating a project, consider the logistics of supply boats, helicopter moves, and remote weather windows that affect timing and expense. The price gap between onshore and offshore is among the most pronounced cost distinctions in oil-well drilling.

Depth, Geology, and Drilling Challenges

Depth is a direct multiplier of cost: deeper wells require longer drilling days, more casing sections, and higher risk of complications. Geological stiffness, high-pressure zones, or abrasive formations can wear drilling equipment faster, increasing wear costs and downtime. Difficult formations often necessitate more advanced drilling techniques, such as managed-pressure drilling or reservoir-specific cementing, further raising the price. Weather conditions and remote locations compound risk and extend the schedule, adding to daily rig rates and standby costs.

Permitting, Leasing, and Regulatory Fees

Beyond the drill string, regulatory processes, land leases, and permitting can add a meaningful portion to the budget. In some regions, environmental impact assessments, habitat clearances, and local taxes can influence permit timelines and fees. Proactive planning, pre-approval, and early stakeholder engagement help avoid costly delays. Keep in mind that permit validity periods and renewal costs can differ significantly by jurisdiction, influencing project cash flow planning.

Surface vs Subsurface Costs: Casing, Cementing, and Completion

Surface facilities and subsurface completion drive a large share of the total cost. Casing strings, cementing programs, and wellhead hardware must be sized to the expected pressure and production profile, influencing both upfront capex and ongoing operations. Completion strategies—such as fracturing, perforation, and stimulation—add further expense but can improve recovery and project economics. The balance between robust well integrity and cost efficiency is a key decision point for planners.

Financing, Risk, and Pricing Models

Oil-well budgets are not just about hardware costs; financing terms, debt service, and risk premiums shape the total exposure. Operators often use staged budgeting, contingency reserves, and scenario planning to absorb price swings and schedule delays. Pricing models may rely on day-rate benchmarks, turnkey contracts, or unit-price arrangements for later stages. Understanding market cycles and hedging strategies can help manage the financial risk of drilling campaigns.

How to Build a Realistic Cost Estimate for Your Well

Start with a detailed scope: well depth, target reservoir, completion design, and equipment needs. Break the estimate into modules—rig and crew, fluids and cementing, casing and wellhead, surface facilities, and regulatory costs. Gather quotes from multiple service providers and include a contingency (commonly 10-20%) to cover unknowns. Build a live budget that accounts for currency fluctuations, logistics, and weather exposure, updating it as the project plan evolves.

Case Scenarios: When Costs Spike or Save Money

Consider three typical scenarios that illustrate cost variability: shallow onshore wells in well-connected basins vs. remote locations with difficult access; mature fields requiring extended reach and fracking; and offshore projects in high-activity regions where port congestion or weather windows create delays. In each case, proactive planning, prequalification of suppliers, and staged procurement can help control costs. Use these case examples as sanity checks during initial budgeting.

Estimated cost components for oil well drilling

| Cost Component | Typical Range (USD) | Notes |

|---|---|---|

| Rig and crew | 1,000,000-5,000,000 | Onshore rig rates and mobilization |

| Drilling fluids and cementing | 100,000-3,000,000 | Mud programs and cementing materials |

| Casing and completion | 500,000-8,000,000 | Casing, cementing, and wellhead |

| Offshore mobilization & platform prep | 50,000,000-150,000,000 | Deepwater or multi-well campaigns |

Got Questions?

What is the typical cost range to drill an oil well onshore?

Onshore drilling costs vary by depth and location, but typical drilling plus basic completion generally falls in the $1 million to $5 million range. Variations come from terrain, access, and regulatory requirements.

Onshore wells usually cost between one and five million dollars, depending on depth and location.

How much do offshore oil wells cost compared to onshore?

Offshore wells are substantially more expensive due to mobilization, specialized rigs, and safety requirements; costs can run from tens to hundreds of millions, depending on depth and water depth.

Offshore wells cost far more, often tens to hundreds of millions.

What factors most influence drilling costs?

Depth, formation, rig type, and completion design dominate cost; weather, regulatory needs, and nearby logistics also shape budgets.

Depth and rig type are the big ones, plus completion plans.

Are there standard cost ranges by well type?

Ranges exist, but they vary widely by region and complexity. Onshore basic wells are typically in the low to mid millions; offshore, higher still.

Yes, but ranges vary a lot by region and complexity.

What other costs should I budget for besides drilling?

Permits, land leases, seismic surveys, cementing, surface facilities, and tie-ins can add substantially to the project budget.

Permits, leases, and completion work can add a lot.

“"Budgeting oil-well costs is a dynamic, driver-driven process; map rig rates, completion plans, and site conditions to reduce uncertainty."”

Top Takeaways

- Start with a realistic baseline: $1M-$5M onshore.

- Offshore costs are significantly higher and more volatile.

- Depth, geology, and completion scope drive most variance.

- Permitting and leases should be modeled early in budgeting.

- Build a phased, contingency-enabled budget to manage risk.