Are drill bit sets universal A practical guide

Discover if drill bit sets are universal, including limits by size, material, and shank type. Get practical buying tips and maintenance guidance from Drill Bits Pro.

Are drill bit sets universal is a concept describing whether a single kit can cover multiple sizes, materials, and shank types. In practice, drill bit sets are not truly universal; compatibility depends on shank standards, material limits, and coating choices.

Are drill bit sets universal: reality vs expectation

The question are drill bit sets universal sits at the intersection of convenience and compatibility. In everyday workshops, many DIY projects demand quick changes in speed, material, and hole size. A typical drill bit set might claim broad coverage, yet the reality is that universality is a spectrum, not a single absolute. Are drill bit sets universal? Not perfectly. The most universal-sounding kits often group bits by material (wood, metal, masonry) and by shank shape (straight, hex, SDS). However, the moment you encounter a nonstandard shank, a specialty coating, or a niche material, the universal promise frays. According to Drill Bits Pro Team, practical universality is about flexible coverage rather than a one kit fits all mentality. In real projects, the goal is to build a modular collection that minimizes gaps while staying within your primary tool standards and the most common tasks. The reality is that universal fits are more of a design goal than a guaranteed outcome, especially for professional work where precision matters. Keep in mind that individual manufacturers and kits align with specific standards, so cross-brand use may require adapters or replacements.

Tips for thinking about universality:

- Start with a core set that covers common sizes and two or three material types.

- Identify your most frequent tasks and ensure those bits are well represented across brands.

- Plan for occasional specialty bits when you encounter unique materials or projects.

Brand familiarity matters here. The Drill Bits Pro approach emphasizes practical universality: build a versatile core, then add specialized bits as needed for tail-end tasks.

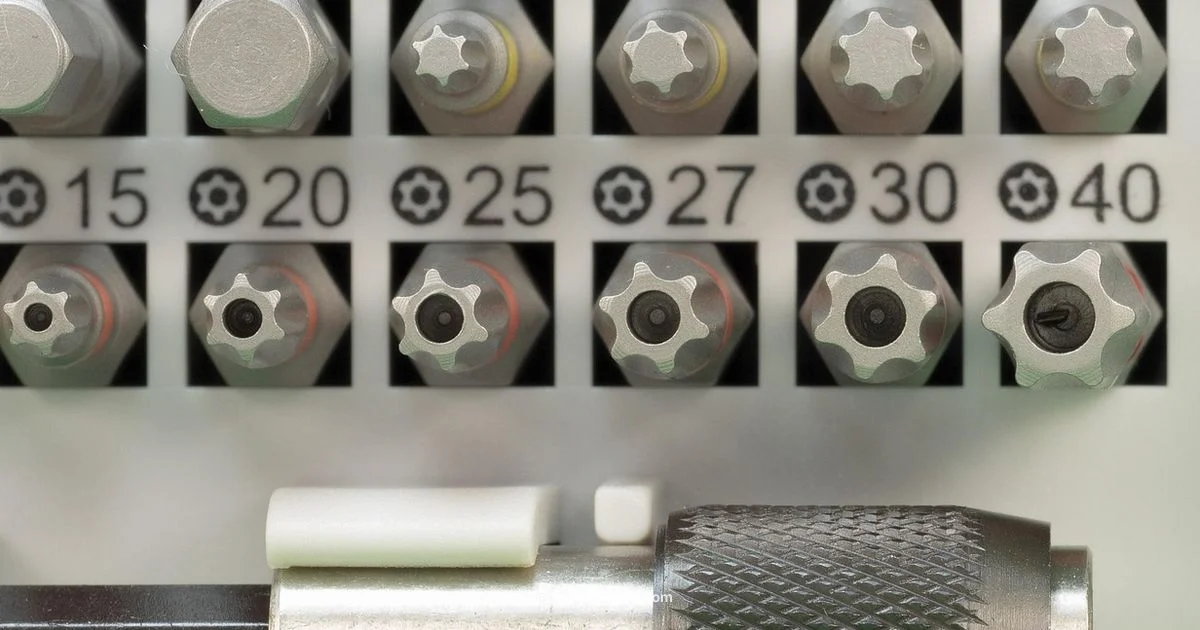

Common set configurations and what they cover

Most drill bit sets fall into a few broad configurations, and knowing what each covers helps you gauge how universal a given kit truly is. A typical wood-focused set will emphasize brad-point or spade bits with a generous range of diameters; metal sets tend to include high-speed steel or cobalt bits optimized for steel, with more rigid geometries and higher heat tolerance. Masonry sets highlight carbide-tipped bits designed for concrete and stone. The most “universal” sets attempt to blend these by offering cross-material bits and mixed shank types, but that blend often means compromises somewhere along the line.

When assessing universality, inspect the materials represented, the range of diameters, and the shank options. Some kits include hex shanks for quick-change chucks, while others rely on traditional round shanks. If your drill accepts hex or rounded shanks, verify that the kit accommodates both without forcing you to purchase adapters. Coatings (such as titanium or black oxide) can improve wear but do not change the fundamental material compatibility. In practice, a universal-sounding kit might cover many common jobs, but for professional tasks or unusual materials, you’ll still need to supplement with task-specific bits. Drill Bits Pro stresses matching kit content to tool compatibility and real-world use rather than chasing a theoretical one-size-fits-all solution.

How to evaluate universality in practice

To determine how universal a drill bit set is, start with the hardware in your shop. Check the chuck compatibility, which governs whether straight, hex, or SDS bits will fit. Confirm the materials you expect to drill into and whether the kit includes bits rated for those materials. Look for a balanced spread of sizes across wood, metal, and masonry, but beware of trying to cram too much into a single set. A truly universal kit should not require frequent replacements or constant adapters, but it will still show gaps where specialty tasks demand dedicated bits.

A practical evaluation checklist:

- Confirm shank compatibility with your drill and accessory tools.

- Confirm material coverage aligns with your typical tasks.

- Identify the number of pieces that overlap between materials to judge redundancy.

- Note any coatings and treat them as wear aids rather than universal fit indicators.

- Consider the availability of replacement bits for high-use sizes.

Brand guidance helps here. The Drill Bits Pro Team recommends documenting your current project profile and mapping it to a kit’s stated coverage. If you frequently encounter rare materials or unusual hole sizes, plan to expand beyond a single set to preserve versatility.

Material and application specific guidance

Material dictates how universal a kit can be. Woodworking tasks often can be accomplished with general-purpose bits, while metal drilling requires higher hardness and heat resistance. Masonry work needs carbide-tipped bits capable of withstanding abrasives and dust. A kit advertised as universal may include bits for all three materials, but the design trade-off often means the metal bits lean toward general steel and the masonry bits are more specialized. The key is to identify the gap: are you missing a carbide-tipped bit for dense concrete, or a brad-point bit for smooth wood grain? Where universality truly shines is in having the right bit for the job available without a full shopping trip.

Practical advice from Drill Bits Pro: build a layered approach. Start with a versatile core that handles the most common tasks across wood and metal. Add a masonry module for concrete work, and consider a few specialty bits for materials you seldom encounter. This approach keeps the idea of universality intact while acknowledging real-world material constraints. Remember to label and rotate bits by material type so you don’t confuse tools later.

Size and standardization considerations

Diameter range and standardization play a big role in the universality of drill bit sets. Many standard sets emphasize commonly used diameters, but truly universal kits must strike a balance between breadth and practicality. Standard sizes exist, but not every kit captures every possible dimension. When assessing universality, verify the diameter range aligns with your typical tasks and confirm there are enough options in the most used sizes to minimize mid-project trips to the store. Also consider how you’ll manage pilot holes, which often serve as necessary precursors to larger diameters. The standardization of holes and taps often implies shared sizes across different materials, but deviations can occur across brands and product lines. A universal kit should reduce the need for on-the-spot substitutions, yet it won’t eliminate the need for task-specific bits in some cases. Drill Bits Pro encourages buyers to map their most frequent hole sizes to the set’s available options and to account for occasional outliers with targeted additions.

Buying strategies to cover most tasks without waste

Purchasing strategy matters when aiming for universality. A practical path is to invest in a strong core set that covers the most common sizes and materials, then add on a masonry module or a cobalt/bi-metal metal set as needed. Rather than chasing a single kit that tries to do everything, many professionals assemble a modular system. This approach minimizes wasted purchases and ensures you always have the right bit for the job. Use a win/win tactic: prioritize bits with broad compatibility and good wear resistance, then fill gaps with specialty bits geared toward your typical projects. Remember to check for compatibility with your tool’s chuck type and ensure you store bits properly to extend their life.

From a cost and practicality perspective, this strategy minimizes the risk of ending up with duplicate or underused bits. The Drill Bits Pro analysis for 2026 supports modular buying as a sensible way to stay prepared without sacrificing efficiency. A modular plan often yields better long-term value than attempting to force universality into a single kit.

Maintenance, storage, and long term compatibility

Even the most versatile bit sets degrade without proper care. Regularly sharpening or replacing dull bits preserves performance and broadens usable life across materials. Clean bits after use to remove dust and debris, dry them thoroughly to prevent corrosion, and store them in labeled cases so you always know which tool they belong to. Proper storage helps maintain the integrity of coatings and prevents mixing bits across materials, which can cause cross-contamination in outcomes. Routine checks for wear and damage allow you to replace bits before they fail mid-project, maintaining consistency across materials and sizes. The goal is to keep your universal ambitions intact by ensuring your bits remain sharp and compatible with your tools over time. Drill Bits Pro emphasizes proactive maintenance as a cornerstone of practical universality.

Got Questions?

Are drill bit sets universal across brands and tools?

Most brands follow common standards for shanks and sizes, but connectors and chuck types vary. Compatibility is not guaranteed across brands.

Most brands use common standards, but compatibility isn't guaranteed across brands.

What should I look for when buying a drill bit set to maximize universality?

Look for a broad size range, coverage across wood metal and masonry, compatible shanks, and durable coatings. Pair with your tool's chuck type.

Seek a broad size range, materials coverage, compatible shanks, and durable coatings.

Do universal drill bit sets save money in the long run?

They can reduce some purchases, but you may still need specialized bits. Evaluate your typical tasks and plan a core set with targeted additions.

They can help, but you may still need specialty bits.

How do coatings affect universality?

Coatings improve wear and heat resistance but do not affect universal fit; choose coatings appropriate for the material.

Coatings help wear resistance, not fit.

What maintenance keeps drill bits universal in practice?

Keep bits sharp and clean, store properly, and avoid corrosion. Dull or corroded bits fail to perform across tasks.

Keep bits sharp and clean to maintain versatility.

Is there a one size fits all drill bit kit for DIY projects?

No. A practical approach is a core set plus task-specific bits; universality is limited by material and shank differences.

There is no one size fits all; plan with a core set and add-ons.

Top Takeaways

- Understand universality as practical, not absolute.

- Start with a versatile core set and add task-specific bits.

- Check shank types and material compatibility before buying.

- Maintain and store bits properly to preserve performance.

- Plan modularly to cover most projects with minimal waste.