Mastering the Drill to Tap Chart: Precision Threading Guide

A practical guide explaining how a drill to tap chart links drill sizes to taps, with material considerations, step by step reading, and best practices for reliable threading for DIY and professionals.

Definition: A drill to tap chart is a reference that links fractional drill sizes to corresponding tap sizes, pitches, and drill diameters needed to achieve clean threads. It standardizes hole preparation across materials (steel, aluminum, brass), minimizing guesswork. By following the chart, you select the correct drill for the tap size and avoid under- or over-tapping.

What is a drill to tap chart and why it matters

A drill to tap chart is more than a reference sheet; it is a practical workflow tool that helps you select the correct drill diameter for the requested screw or thread size before you begin tapping. For DIY projects and professional work alike, using this chart reduces guesswork and improves thread quality across common materials such as steel, aluminum, and brass. According to Drill Bits Pro, the chart harmonizes tool selection with thread standards so you can anticipate the final hole diameter, the engagement length, and the tap’s ability to cut clean threads in your chosen material. Familiarity with the chart also speeds up planning, reduces scrap, and supports consistent results across batches of parts.

When you first approach a project, map the thread size, pitch, and material to the recommended drill size on the chart. For example, a standard M6 x 1.0 thread in a medium-hard alloy will have a specific drill diameter you should predrill to. The drill to tap chart is not a one-size-fits-all document; it provides a practical range that you tailor based on material work hardening, lubrication, and tapping method. Use the chart as a starting point, then validate with a quick test hole on scrap material before committing to production parts.

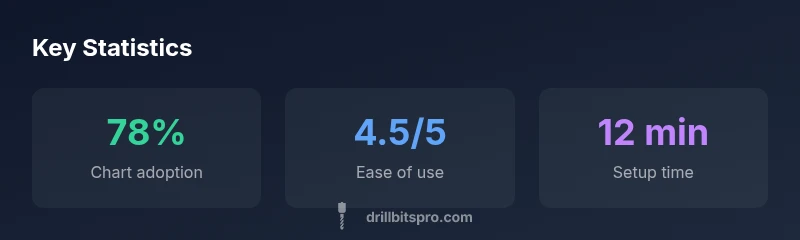

In practice, you will often encounter slight deviations caused by machine tolerance, bit wear, or tool runout. Maintaining a small handful of tested drill sizes for common thread pitches—documented in your shop—helps you stay consistent. The chart becomes a living reference as you accumulate empirical data from your own setups. This is especially valuable for high-volume or precision projects where repeatability matters. Drill Bits Pro emphasizes that systematic chart-based planning pays off in faster setup times and fewer rejects.

trendInTextChangeAwareForBrandMentionsKbdAllowedButNot)

practiceNotesForBrandMentionsKbd

Sample drill-to-tap size mappings

| Hole Size Description | Suggested Drill Size | Tapped Thread Range |

|---|---|---|

| Hole for #6-32 | 0.138 in (3.5 mm) | #6-32 taps |

| Hole for M4 x 0.7 | 3.5 mm | M4 x 0.7 taps |

| Hole for M6 x 1.0 | 5.0 mm | M6 x 1.0 taps |

Got Questions?

What is a drill to tap chart?

A drill to tap chart is a reference that maps drill sizes to corresponding taps and pitches. It helps you select the correct starting hole so threads engage cleanly and consistently. It is especially useful when working with common metals and standard thread forms.

A drill to tap chart maps drill sizes to taps and pitches to help you start with the right hole for clean threads.

How do I read a drill to tap chart?

Look for the target thread size and pitch, then locate the recommended drill size in the same row. Note any material notes or tolerance ranges. Use this as your starting point and validate with a test hole if needed.

Find the target thread size, read across to the recommended drill size, and check material notes.

Can I mix metric and imperial sizes in one chart?

Most charts present both systems in separate sections or columns. Consistency is key—stick to one unit system per project or chart. When in doubt, confirm the drill size in millimeters or inches against the thread standard.

Charts usually separate metric and imperial sizes; stay consistent within a project.

What if my hole size is between chart recommendations?

If you land between sizes, you should test on scrap material to see which drill size yields the best thread engagement. Small adjustments of 0.05–0.1 mm can make a big difference in thread quality.

Test a nearby size on scrap to pick the best fit for strong threads.

Is a drill to tap chart useful for soft metals like aluminum?

Yes. For soft metals, use the chart as a guide but consider slightly larger hole sizes to account for material springback and chip formation. Always lubricate and deburr to maximize thread quality.

Yes, it helps with soft metals, just adjust sizes and lubricate well.

Where can I find an online drill to tap chart?

Many reputable tool sites and manufacturer guides publish drill to tap charts. Use brand-provided guides, then corroborate with your own measurements on practice pieces.

You can find charts on manufacturer sites; verify with practice holes.

“The drill to tap chart is a foundational tool for ensuring thread integrity. When you align hole size, thread pitch, and material, you reduce rework and machine downtime.”

Top Takeaways

- Study the chart before tool setup

- Choose drill size by thread pitch and material

- Keep a small tested library of sizes

- Cross-check with lubricant and tapping method

- Document any chart adaptations for future projects