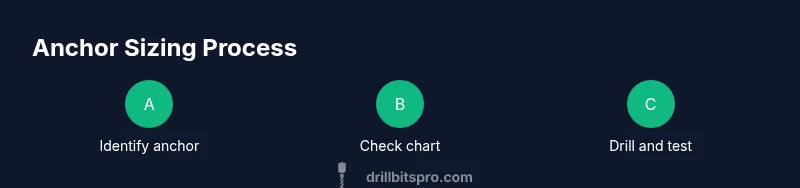

How Big Should Drill Bit Be for Anchor: Expert Sizing Guide

Learn how to size drill bits for anchors across wood, drywall, and concrete. This guide explains manufacturer charts, substrate considerations, and step-by-step sizing to ensure strong, safe holds.

According to Drill Bits Pro, the drill bit size for an anchor should follow the manufacturer's recommended size. Start with a pilot hole slightly smaller than the anchor’s outer diameter, then test-fit the anchor and adjust as needed. When in doubt, refer to the chart on the packaging. This quick rule applies across most common anchor types.

Why drill bit size matters for anchors

Choosing the correct drill bit size is the foundation of a secure anchor install. If the hole is too small, the anchor won’t insert properly and the screw may strip the material. If the hole is too large, the anchor cannot grip, leading to a loose hold that fails under load. The size you choose depends on the anchor type, the substrate, and the anticipated load. This is why the question how big should drill bit be for anchor comes up so often among DIY enthusiasts and professionals alike. In this comprehensive guide, we break down the logic behind sizing and provide practical steps you can apply on the job. According to Drill Bits Pro, following the anchor manufacturer’s drill size is the best starting point, then verifying fit before full installation.

How anchor type affects drill bit sizing

Not all anchors are created equal, and different anchor systems use different drill sizes. Plastic wall anchors rely on a tapered hole that matches the anchor’s outer diameter, while expansion anchors (for masonry or concrete) require a hole that accommodates the expanded sleeve. Sleeve anchors and lead-in plugs often need a slightly different hole to allow the anchor to seat flush against the substrate. When you ask how big should drill bit be for anchor, the answer must reflect the specific anchor you’re using. Always check the packaging, because manufacturers publish exact drill sizes for each product. If you’re using multiple anchors in a project, keep a small chart handy that lists the recommended drill size next to each anchor type.

Reading manufacturer charts and general rules

Anchor packaging and manufacturer guides are your fastest route to the correct size. A common rule of thumb is: the drill size equals the anchor’s recommended size, but for plastic anchors you can sometimes go one size up or down depending on wall material. In masonry, use a masonry bit of the recommended size and clean the dust between attempts. If a chart is missing or unclear, choose a bit that allows the anchor to insert snugly with minimal resistance, then test fit with the screw. Remember that different brands may use slightly different conventions, so always cross-check the exact part number with the documented size.

Substrate considerations: wood, drywall, concrete

Substrate strongly influences hole behavior and anchor performance. In wood, drill a pilot hole that minimizes splitting while still allowing the anchor to seat firmly. In drywall, use the proper drywall anchors and a hole sized to match the drywall’s thickness and the anchor’s design. For concrete or masonry, select a masonry bit sized to the anchor and drill to the recommended depth. Longer anchors may require deeper holes, but avoid over-drilling, which reduces grab. If you’re unsure, perform a quick dry-run on a scrap piece to confirm the fit before committing to the actual work.

How to verify you picked the right size before drilling

Before committing to a full installation, verify the hole size with a test insert. Dry-fit the anchor into the drilled hole to confirm it sits flush and can be pulled out smoothly with moderate resistance. If the anchor binds or sticks, recheck the bit size against the manufacturer chart and consider a slightly different bit size. Dust removal is critical—dust left in the hole can reduce grip and lead to a weaker hold. Practicing on a scrap board helps you fine-tune the size without damaging the final surface.

Common mistakes and how to fix them

Common mistakes include drilling too small, which makes insertion difficult and can crack the substrate; or drilling too large, which prevents the anchor from gripping and creates a hollow feel. Another frequent error is skipping dust removal, which fouls the contact surface. Finally, never reuse damaged anchors or force-fit an anchor into a hole that’s not the correct size. If you make a sizing mistake, fill the hole with an appropriate filler and re-drill with the correct size to restore holding power.

Quick sizing checklist for fast jobs

When you’re pressed for time, use this quick reference: identify the anchor type, locate the recommended drill size on the packaging, drill a test hole in a scrap piece, and verify that the anchor seats flush with the surface. If the test shows resistance or excessive looseness, adjust by one size up or down according to the manufacturer’s guidance. Always enjoy a safety-first approach: wear eye protection, work patiently, and keep the drill at a steady speed to avoid wandering.

Tools & Materials

- Drill (cordless or corded)(Variable speed preferred; ensure battery life or cord reliability)

- Anchor kit (plastic or masonry)(Contains sleeves, plastic anchors, or masonry sleeves and screws)

- Measuring tape(For depth and position marking)

- Pencil or marker(Mark center points and depth indicators)

- Vacuum/brush(Clean dust from holes for better seating)

- Safety glasses(Eye protection required during drilling)

- Dust mask(Optional, for dusty materials)

Steps

Estimated time: 30-45 minutes

- 1

Identify anchor type and recommended drill size

Identify the anchor type you plan to install and locate the manufacturer’s recommended drill size on the package or product page. This size is the baseline for your pilot hole.

Tip: Double-check the exact part number to ensure you’re using the correct chart. - 2

Prepare the drilling location

Mark the hole center with a pencil and ensure the surface is clean. Align the drill perpendicular to the surface to avoid angled holes that weaken the anchor.

Tip: Use masking tape to prevent the drill bit from wandering on slick surfaces. - 3

Drill the pilot hole to the correct depth

Set a depth stop or use a spacer to drill to the anchor’s required depth. Drill slowly to reduce wandering and heat buildup.

Tip: Pause briefly to clear dust and inspect the hole after a test bite. - 4

Clean the hole thoroughly

Vacuum or brush out dust from the hole so the anchor seats flush. A dirty hole can reduce grip and cause misalignment.

Tip: Run a few light taps with a hammer if required to settle loose dust. - 5

Insert the anchor

Gently tap or screw the anchor into the hole until it sits flush with the surface. Do not force it beyond flush; over-driving damages the substrate.

Tip: Use a small wooden block as a tapping pad to avoid marring the surface. - 6

Drive the screw and verify holding power

Replace the screw with the appropriate driver and torque to the recommended load. Verify by applying moderate force to ensure a solid hold.

Tip: If the anchor spins, remove and reset with a slightly larger drill size only if manufacturer allows.

Got Questions?

How do I know the correct drill bit size for a specific anchor?

Start with the manufacturer’s recommended drill size for that anchor. If that isn’t available, choose a bit that allows the anchor to insert snugly and test-fit before final installation.

Use the manufacturer’s recommended size and test-fit to ensure a snug hold.

What if I don’t have the exact drill bit size?

Use the closest size listed by the manufacturer and test it in a scrap hole or a non-critical location. If it’s too tight, go down one size; if too loose, go up one size only if the manufacturer allows.

If you don’t have the exact size, test with the closest size and adjust.

Can I reuse anchors if the hole was drilled too large?

A hole drilled too large often cannot hold an anchor securely. It’s better to fill and re-drill with the correct size. Always start with the right size from the vendor.

If the hole is too large, reuse is not recommended; re-drill with the correct size.

Are there safety concerns when drilling into masonry?

Wear eye protection and a dust mask. Use a proper masonry bit and keep the drill steady to avoid wandering that can damage the surface.

Always wear safety gear and use a masonry bit for concrete.

Do drywall anchors always require a pilot hole?

Yes. Drywall anchors rely on a pilot hole to sit flush and avoid tearing the drywall. Use the size recommended by the anchor manufacturer.

Drywall anchors need a pilot hole sized per the manufacturer.

Watch Video

Top Takeaways

- Identify anchor type first and read the size chart

- Use the manufacturer’s drill size as starting point

- Test-fit the hole with an anchor before full installation

- Clean the hole to maximize grip

- Verify holding power after installation