Why Do Drill Bits Get Dull and How to Fix It

Learn why drill bits dull, how to recognize wear, and practical sharpening and prevention tips. A comprehensive guide from Drill Bits Pro for DIYers and professionals seeking reliable drilling results.

Dull drill bits are cutting tools whose edges have lost sharpness, resulting in slower cuts and rough holes. They are a type of drill bit that requires sharpening or replacement to restore performance.

What causes drill bits dull

If you ask do drill bits get dull, the answer is yes for most users. Dullness happens when the cutting edges lose sharpness after repeated contact with hard materials, heat buildup, or residue on the edge. In practice, tiny chips, resin, and metal shavings grind away at the tip and flutes, gradually reducing cutting efficiency. The main culprits are running at speeds that are too high for the material, applying uneven or excessive pressure, and drilling without a controlled feed. Heat and friction intensify edge wear, often leaving holes that wander or burn. Recognizing the early signs of wear, such as increased effort to drill, unusual warmth, or smoke, helps you decide whether to resharpen or switch to a fresher bit. From the perspective of DIYers and professionals, maintaining a clean cutting edge is as important as choosing the right material for the job. According to Drill Bits Pro, dullness is often preventable with proper technique, regular maintenance, and mindful material selection.

How heat and speed influence dullness

Heat is the silent destroyer of cutting edges. When a drill bit overheats, the edge loses hardness and becomes prone to microchipping and glazing. Speed magnifies this effect: going too fast for a given material creates more friction, pushing heat into the edge instead of cutting efficiently. Conversely, too slow a pace can cause the bit to rub rather than cut, generating heat through friction without removing material. A balanced approach—matching speed to material, using steady pressure, and allowing brief cooling breaks for metal drilling—extends life. Lubricants or cutting oils reduce heat and carry away chips, especially on metal and hard composites. While wood and softer plastics tolerate higher speeds, the same principle applies: avoid sustained high temperatures that soften the edge. Drill Bits Pro analysis notes that many dullness issues stem from heat buildup coupled with resin and chips that cling to the edge, so keeping edges clean and cool is a primary defense.

Wear patterns by material and bit type

Different materials wear drill bits in distinct ways. Wood bits often dull from crushing fibers and clogging with pitch, while metal bits suffer edge rounding and flute blocking from steel chips. Masonry bits, with carbide tips, resist dullness better but can still wear at the tip or fracture if misused on very hard concrete without proper percussion. High speed steel bits (HSS) are versatile but tend to lose sharpness after repeated metal drilling, whereas cobalt and carbide-tipped bits retain edge retention longer under tough use, albeit at higher cost. Understanding the typical wear patterns helps you diagnose dullness quickly: a rounded edge, increased resistance, and chatter usually point to a dull tip rather than a fault in the drill press alignment. Regularly inspecting the edge under good light makes wear obvious before it affects the workpiece.

How to tell if a bit is dull

A dull bit demonstrates several telltale signs. If cutting becomes noticeably slower, the bit struggles to penetrate, or requires excessive force, it’s a strong indication that the edge is worn. Heat is another red flag: more warmth than usual, smoke, or a blue tint near the tip signal overheating and potential loss of hardness. You may also notice glazing on the edge, where plasticity forms a slick surface that repels material rather than cutting it. Chips and burrs along the flute can signal edge wear or improper sharpening. A practical test is to attempt a shallow cut in scrap material; if the bit slides or rubs rather than bites, or leaves ragged holes, it’s time to sharpen or replace. If you have carbide tips, note that some are not meant to be sharpened with common tools and may require professional services.

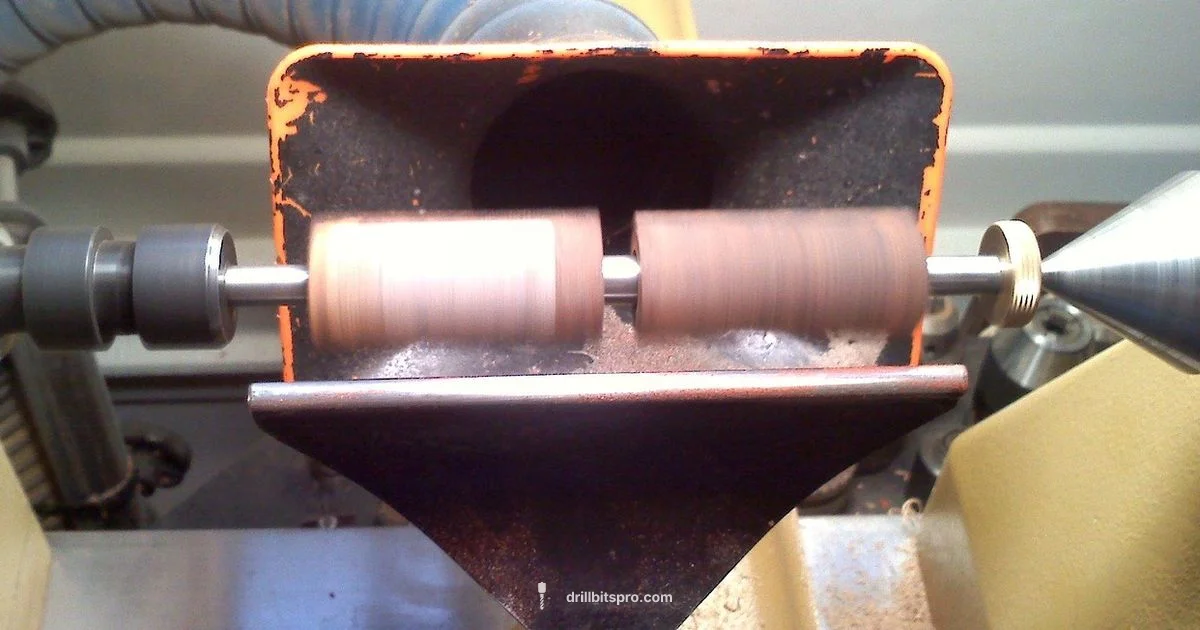

Sharpening and restoring cutting edges

Sharpening a drill bit restores the sharp point and flute geometry that govern cutting efficiency. For twist drills, secure the bit in a vise and restore both lips so they meet at a consistent point. Use a fine file, a sharpening stone, or a dedicated drill bit sharpener to re-create the point angle and remove any built-up glaze. Maintain symmetry between the two cutting edges and avoid removing too much material from one side, which can cause the bit to drill off-center. After sharpening, deburr the edge and check that the point tip remains centered. Carbide tips are harder and more brittle; many professionals rely on diamond wheels or professional sharpening services for carbide bits rather than attempting home sharpening. If the bit’s core body or carbide tip shows signs of breakage, replacement is safer and often more economical in the long run. Regular honing can extend life between full sharpenings, and keeping a flat, clean sharpening surface improves results.

Preventing dullness: technique and maintenance

Prevention is the most reliable strategy. Start by selecting the correct bit type for the material and the cut; wood bits for wood, HSS or cobalt for metal, and carbide for masonry. Use correct speeds and steady, even pressure; avoid pushing the bit into the work without allowing the edge to do the cutting. Apply a light lubricant or cutting oil when drilling metal; this lowers friction and cools the edge. Clear chips frequently to prevent recutting and edge wear. Keep bits sharp by inspecting them after each project and performing light touch-ups as needed rather than letting dullness accumulate. Store bits dry and clean to prevent corrosion, and use protective caps or sleeves to prevent nicks on the cutting edges during transport. By combining the right bit, proper technique, and regular maintenance, you can drastically reduce the rate at which drill bits dull and maximize their lifespan.

Choosing the right bit and lubrication

Selecting the right bit involves more than material type. Consider geometry, flute length, and point angle to suit the job. For metals, pair the drill with cutting oil or lubricant to reduce heat and extend life. For masonry, carbide-tipped bits withstand impact but still benefit from light tapping and controlled percussive action. For wood, standard twist bits work well when paired with a bright feed rate and a clean drill hole free of pitch. Lubrication matters less in soft plastics but can prevent heat buildup during extended metal drilling. Regular maintenance—keeping the tip sharp, clearing chips, and storing tools properly—complements smart bit selection and yields consistently cleaner holes with less effort.

Got Questions?

Do drill bits get dull with use?

Yes. In most projects, cutting edges wear down over time due to heat, friction, and material buildup. The rate of dullness depends on material hardness, bit type, and drilling technique. Regular inspection helps catch wear early so you can sharpen or replace before it affects the hole quality.

Yes. Bits dull with use, especially on hard materials. Regular checks help you decide when to sharpen or replace.

How can I tell if a drill bit is dull?

Look for slower cutting, overheating, blue tint on steel, or ragged holes. If the bit struggles to bite or requires extra force, it’s likely dull. A quick test on scrap material can confirm whether sharpening is needed.

If cutting slows, overheats, or leaves rough holes, the bit is probably dull. Test on scrap to decide on sharpening.

Can I sharpen drill bits at home?

Many bits can be sharpened at home with a file, sharpening stone, or a dedicated sharpener. Carbide tips are tougher but more brittle and often require specialized equipment or professional service. If in doubt, replace worn carbide bits rather than attempting risky sharpening.

Yes, many bits can be sharpened at home, but carbide tips may need professional sharpening or replacement.

Should I lubricate drill bits when drilling metal?

Yes. Using a cutting oil or lubricant reduces heat and wear, improving edge life and hole quality. For wood or soft plastics, lubrication is less critical but can still help with smoother cutting.

Lubricate metal drilling to reduce heat and wear; it helps maintain edge life.

What is the difference between HSS and carbide bits regarding dullness?

HSS bits sharpen relatively easily but wear faster on hard metals. Carbide tips resist wear and stay sharp longer but are more brittle and expensive. For extreme duty, carbide lasts longer but may require specialized sharpening.

Carbide lasts longer but can crack; HSS sharpens easily but wears faster.

How often should I replace a dull bit?

If sharpening does not restore cutting efficiency, or the edge is chipped or cracked, replacement is safer and yields better results. Prolonged use of a dull bit can damage workpieces and extend drilling time.

If sharpening fails to restore performance, replace the bit.

Top Takeaways

- Identify dullness early by watching cutting speed and heat

- Sharpen or replace bits with attention to edge geometry

- Use proper speeds, pressure, and cooling for prolonged life

- Different materials wear bits differently and require appropriate bits

- Maintain a routine of cleaning, sharpening, and proper storage