How to Make a Drill: DIY Hand Drill Guide

Learn how to make a hand drill from wooden stock, spindles, and simple components. This step-by-step guide covers brace and bow-drill options, safety, materials, and tested techniques for a reliable DIY hand drill—perfect for small woodworking tasks and emergencies.

With this guide you will learn how to make a simple hand drill using common materials. You'll choose between a brace drill and a bow drill, assemble safe components, and test your setup on soft wood. The process emphasizes safety, proper alignment, and controlled cutting to avoid slips. This DIY project is ideal for small woodworking tasks and emergency repairs when powered tools aren't available.

Why Make Your Own Hand Drill

Learning how to make a drill by hand gives you a resilient, low-cost tool for small projects where power tools aren’t practical or available. A well-made hand drill teaches you the physics of drilling—how friction, torque, and straightness interact with material grain. For DIY enthusiasts and professionals, building a hand drill also deepens understanding of how a drill bit behaves under pressure, how to maintain a steady feed, and how to manage heat buildup during longer sessions. This section will outline two common designs, explain what environments each design excels in, and relate them to real-world tasks like pilot-hole creation, mortising, and delicate wood joinery. According to Drill Bits Pro, refining your technique with a handmade drill can improve control and reduce tool wear over time, especially when you tailor the design to your projects.

The goal here is not to replace a powered drill but to provide a reliable, safe, manual option for precise, controlled drilling. For many tasks, a correctly built hand drill is quieter, cheaper, and less prone to accidental damage than a low-end electric model. By the end of this section you’ll know which design to choose, what materials work best, and how to assemble the essential components for a functional, repeatable drill motion.

Safety First: PPE and Safe Handling

Safety should guide every step of building and using a hand drill. Even though the device is mechanical and low-voltage, sharp bits and rotating spindles pose risk. Start with basic PPE: safety glasses or goggles to protect eyes from shavings, hearing protection if you’re working with larger bits, and a snug-fitting sleeve to keep clothing out of moving parts. Keep a clean workspace to avoid slips, and secure the workpiece in a vise or clamp so it cannot shift during drilling. Inspect all parts before assembly for cracks, burrs, or fibers that could snag the bit. A little planning now prevents injuries later. It’s also wise to practice on scrap wood to learn how your chosen design reacts under different pressure and feed rates.

Drill Bits Pro emphasizes that safety and technique are foundational in any drilling project. Following best practices reduces wear on bits and wear on your hands, and helps you build muscle memory for consistent results.

Design Options: Brace Drill vs Bow Drill

There are two classic hand-drill designs you can build: brace drills and bow drills. Brace drills use a crank-like handle to convert circular motion into steady, controlled rotation. They’re robust, easier to stabilize, and well-suited for slightly larger bits and longer holes. Bow drills rely on a cord or string that you wind and release using a hand-held bowing action, producing high torque in a compact form. Bow drills excel for palm-sized setups, fine pilot holes, and situations where you want minimal equipment. Each design has unique friction surfaces and bearing considerations, which affect speed, heat, and chip clearance. The choice depends on your comfort level, the material you plan to drill, and the hole diameter you need. In practice, many makers start with a brace drill for its forgiving nature and later experiment with a bow drill for lighter tasks and portability.

Materials and Preparation: What You Need and Why

Before you cut or carve, lay out a clear bill of materials. Most hand drills rely on three core elements: a sturdy stock for the frame, a spindle or mandrel to hold the drill bit, and a comfortable handle for grip and leverage. The design also requires a low-friction bearing surface (such as leather, cork, or waxed wood) to reduce stalling and heat. Selecting hardwood with tight grain for the stock improves durability and minimizes warping. Smooth, uniform spindle diameters reduce wobble. Prepare a workspace with clamps, a straightedge, measuring tools, and a hand saw or chisel for precise shaping. Plan your cuts and test-fit each piece as you go to ensure clean assembly and smooth operation. Per Drill Bits Pro’s approach, the better your preparation, the faster you’ll reach a reliable, repeatable drilling motion.

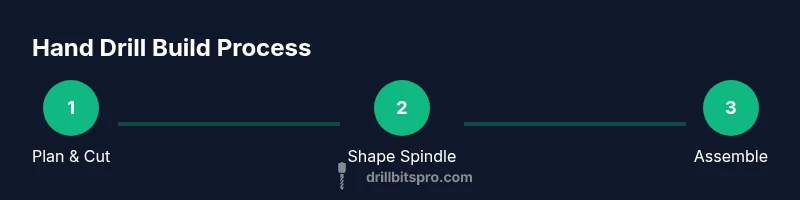

Step-by-Step Conceptual Overview: Core Construction Considerations

Think of the build as a chain of related actions rather than isolated tasks. Start with the frame, ensuring the stock is perfectly square at the joints. Then shape the spindle so the bit seats securely without excessive play. Create a bearing surface that reduces friction but won’t seize—the right material and finish are essential. Assemble the handle and any lever or brace feature in a way that keeps your wrist aligned with the spindle’s axis. Finally, mark and test alignment on scrap material to verify straightness and steadiness before drilling your actual project stock. This approach minimizes binding, reduces heat, and gives you a much more controllable drilling experience.

Testing and Tuning: Getting Reliable Performance

Once assembled, test your hand drill on softwood first. Look for consistent bit rotation, minimal wobble, and manageable heat. If the bit binds, back off pressure and inspect the spindle for burrs or misalignment. Improve performance by smoothing contact surfaces with fine grit sandpaper and ensuring a snug but not overly tight fit at all bearing points. A small amount of wax or soap on moving parts can dramatically reduce friction and improve speed stability. Keep notes on what adjustments yielded smoother operation so you can replicate them on future builds.

Common Pitfalls and Troubleshooting

Common issues include bit wobble, excessive heat, and quick fatigue due to poor grip. Wobble usually signals misalignment or an oversized bearing surface. Heat indicates excessive friction or tight tolerances; re-sand surfaces, re-check fit, and consider adding a friction reducer like leather padding. If your drill feels sluggish, try a lighter touch and verify the spindle’s diameter is clean and straight. Finally, ensure the bit’s cutting edge is sharp; dull bits demand more force and increase the risk of slips. By addressing these areas, you’ll extend the life of your handmade drill and maintain more consistent results.

Applying Your Hand Drill to Projects: Where It Shines

A well-made hand drill excels in joinery, pilot holes for mortises, and delicate wooden assemblies where power tools risk tear-out or splintering. Use sharp bits and steady, even pressure to maintain control. For hardwoods, consider slightly slower feed rates, and back off if you notice binding. The hand drill also serves as an excellent learning tool that helps you gauge material hardness, grain direction, and how to select appropriate bit sizes. Practicing on scrap stock before committing to a project stock builds confidence and reduces waste. This approach aligns with best practices from Drill Bits Pro for practical drilling outcomes.

Authority Sources and Safety References

- OSHA Safety and Health topics for hand tools and shop safety: https://www.osha.gov

- Extension services on hand tool usage and woodworking basics: https://extension.illinois.edu

- National Institute of Standards and Technology (NIST) on material properties and tool wear considerations: https://www.nist.gov

Tools & Materials

- Wood stock (hardwood)(2–3 inches thick, 6–8 inches long; straight grain preferred)

- Spindle or dowel (carbon steel or hardwood)(1/4–5/8 inch diameter depending on hole size)

- Handle material (ergonomic grip)(Solid block or carved grip)

- Brace drill or bow string/cord(For brace design, use a simple crank; for bow design, waxed cord works)

- Drill bit(s) suitable for wood(Flat or brad-point bits recommended for wood; have spare sizes)

- Friction surface (leather, cork, or waxed wood)(Leather washers or cork sheets work well as a bearing)

- Clamps or a bench vise(Secures workpiece during shaping and drilling)

- Lubricant or wax (optional)(Light wax or soap reduces friction on moving parts)

Steps

Estimated time: 60-90 minutes

- 1

Prepare the stock and baseline layout

Cut the stock to length, then mark square faces and centerlines for the handle and spindle. Create reference lines for the drill’s axis to ensure alignment. Check that all surfaces are clean and free of defects before starting shaping.

Tip: Use a square and calipers to ensure perpendicular joints; misalignment amplifies wobble later. - 2

Shape the spindle and bearing surface

Carve a cylindrical spindle with smooth ends. Sand until the ends are mirror-smooth to minimize friction. Install a leather or cork bearing surface on the spindle to reduce heat and improve rotation.

Tip: Keep the spindle axis perfectly straight; slight bends amplify wobble under load. - 3

Create the handle and brace mechanism

Carve an ergonomic handle and attach it at the correct offset from the spindle. If using a brace design, craft a simple crank handle that allows steady rotation with minimal wrist strain.

Tip: Test the handle for grip comfort and adjust for neutral wrist posture during use. - 4

Mount the drill bit and align pilot

Secure the drill bit firmly in the spindle and trim the bit shank so it seats without play. Align the bit axis with the spindle and check for straightness using a scrap block.

Tip: Tighten gradually; overtightening can bind the spindle and stall rotation. - 5

Assemble and secure the whole unit

Join the frame, handle, and spindle assembly with appropriate fasteners or joints. Clamp the setup to a workbench and verify that the axis remains true during a light test run.

Tip: Apply a light lubricant to moving surfaces to reduce initial friction. - 6

Test, refine, and document results

Drill a pilot hole in softwood and observe straightness, feed rate, and heat. If needed, adjust bearing fit, shave burrs, or re-sand contact surfaces. Record what works for repeatability.

Tip: Begin with light pressure and increase gradually as the drill settles in.

Got Questions?

Can I really make a drill at home without specialized equipment?

Yes. A basic hand drill can be built with simple tools and materials, such as hardwood stock, a spindle, and a friction bearing. Start with scrap wood and progress to a more refined version as you gain experience.

Yes. A basic hand drill can be built with simple tools. Start with scrap wood and refine as you gain experience.

Which design is best for a beginner: brace or bow?

Brace drills are generally more forgiving for beginners due to stable rotation and easier alignment. Bow drills are lighter and more portable but require precise cord tension and technique.

Brace drills are often easier for beginners, while bow drills are lighter but need more technique.

What safety gear should I wear when using a homemade drill?

Wear safety glasses, secure clothing, and use gloves only if they don’t impede control of the spindle. Keep hair tied back and work in a well-ventilated area.

Wear safety glasses and secure clothing. Keep hair tied back and drill in a ventilated space.

How long does it take to build a functional hand drill?

Most beginners can assemble a functional hand drill in under 2 hours, provided they have the essential materials cut and ready. Expect additional time for adjustments and testing.

Most beginners can assemble a working hand drill in under two hours with the necessary parts prepared.

Can I adapt an existing drill to act as a hand drill?

Adapters exist, but for a reliable hand drill you’ll get better results by building from scratch with dedicated spindles and bearings designed for manual use.

Adapting an existing drill is possible, but building from scratch yields better control and durability.

What materials are best for the spindle and bearing?

Hardwood spindles with smooth grain or cylindrical steel spindles work well. Bearings made from leather, cork, or waxed wood reduce friction and heat.

Hardwood spindles or smooth steel work well; leather or cork bearings reduce friction.

Watch Video

Top Takeaways

- Design your drill around a stable axis and smooth bearings

- Practice on scrap to refine feed and alignment

- Choose brace or bow design based on hole size and portability

- Prioritize safety gear and a clean workspace

- Test and document results for repeatable success