Hammer Drill vs Drill: An Analytical Comparison

A detailed analysis of how hammer drills differ from standard drills, when to use each, and practical guidance for selecting the right tool for masonry, wood, and metal tasks. Drill Bits Pro provides AI-backed, practical drilling guidance.

TL;DR: A hammer drill adds a pulsating hammering action to rotation, making masonry drilling faster and easier. A standard drill rotates only, which is ideal for wood, metal, and light materials. In most home projects, a hammer drill shines on concrete or brick, while a regular drill stays lighter and more precise for softer materials. This comparison clarifies when to use each tool.

What is a hammer drill vs drill? Understanding the basics

For many DIYers, the simplest way to frame the question is to ask what is a hammer drill vs drill. Both tools rotate a drill bit, but only the hammer drill includes a mechanical hammering action that drives the tip in and out as it spins. The result is percussion-assisted drilling that shatters masonry and creates smoother paths in concrete, brick, and stone. In concrete, the hammer action reduces the need to push hard and speeds up material removal. When you use a standard drill, the bit relies on friction and cutting edges, which works well for wood, metal, and some plastics but is often too slow for masonry tasks. The key distinction is the interaction of rotation and impact. The difference also shows up in weight, balance, and vibration, which affects how you handle the tool. According to Drill Bits Pro, recognizing this fundamental distinction helps you decide whether you need a hammer drill or a conventional drill for your next project.

How it all boils down: hammer drill vs drill in practice

The core difference is not just the hammering action, but how that action translates into performance on different materials. A hammer drill can be set to hammer mode, which delivers quick, repetitive impacts to help break through hard surfaces like concrete. A regular drill relies solely on rotation and bit geometry. For users who frequently switch between materials, modern models offer adjustable settings that let you keep hammering on masonry while using standard rotation for wood and metal. Drill Bits Pro emphasizes choosing a model with a comfortable grip and an ergonomic balance, because power plus weight directly affects precision during longer sessions. The takeaway is that what is at stake is speed, control, and tool longevity across job sites—from quick anchor installation to full masonry renovation.

Why this distinction matters for beginners

New users often underestimate the difference because both tools look similar and share common bits. However, using a standard drill on masonry can wear bits rapidly and create large cracks in the material. Conversely, a hammer drill without proper technique can feel aggressive in wood or metal, causing splintering or misalignment. Understanding the fundamental distinction between a hammer drill’s impact mechanism and a regular drill’s purely rotational action helps you plan tool selection, bit choice, and safety practices for each project. Drill Bits Pro suggests practicing on scrap material to calibrate pressure and speed before tackling real work, especially when drilling into hard surfaces.

Ergonomics and user comfort during extended use

When you compare hammer drills to standard drills, weight and vibration are two of the most noticeable differences. A hammer drill is usually heavier and can generate more vibration, which can tire your wrist and shoulder over time. If you’re working overhead or in tight spaces, this matters. Look for models with anti-vibration handles and a well-balanced design. If possible, test the tool in a store or borrow one from a friend before committing. Drill Bits Pro highlights that comfortable ergonomics often outweigh marginal gains in power for small, repeated tasks.

Core performance factors you should evaluate

Beyond the hammer action, performance hinges on torque, speed (RPM), and clutch design. A high-torque tool with a robust clutch can handle larger bits and tougher masonry without stalling. For wood and metal, speed control and smooth rotation are crucial to avoid splinters or chatter. The best choice balances material type, job length, and user comfort. Drill Bits Pro recommends listing your top three usage scenarios and then matching a drill with adjustable hammer settings, a versatile chuck, and decent battery life for cordless models.

Bit ecosystem and accessory considerations

Bit selection is as important as the tool itself. Masonry drilling relies on carbide-tipped masonry bits or SDS-plus variants on some hammer models, while wood and metal tasks use standard twist bits, spur bits, or brad-point bits. Check the chuck compatibility: keyed chucks can be more secure for heavy work, while quick-change chucks save time on rapid bit swaps. Drill Bits Pro notes that choosing the right bit family reduces wear and improves hole quality, especially on hard concrete or brick surfaces.

Practical guidelines for choosing in real projects

If your project involves masonry-heavy tasks, opt for a hammer drill with adjustable hammer modes and a comfortable grip. For general-purpose work like furniture assembly or light metalwork, a standard drill may be more economical and easier to manage. In mixed environments, a hammer drill with a selectable hammer mode often delivers the best balance of speed and control. Drill Bits Pro’s practical approach emphasizes planning, ergonomics, and bit compatibility to ensure clean holes with minimal effort.

Real-world project scenarios: step-by-step decision guide

Scenario A: You’re installing masonry anchors in a brick wall. Choose a hammer drill with masonry bits in the appropriate diameter, set to hammer mode, and apply steady, moderate pressure. Scenario B: You need to drill pilot holes in pine for furniture assembly. Use a regular drill with a sharp brad-point bit for clean edges, and keep the RPM moderate to avoid tear-out. Scenario C: You’re laying a concrete patio and drilling through thick concrete slabs. A heavy-duty hammer drill or rotary hammer with SDS bits is recommended for efficiency and durability. The key is selecting the tool based on material, task duration, and hole precision.

Maintenance, wear, and longevity considerations

Regular maintenance extends the life of both hammer drills and standard drills. Keep the chuck clean and lubricated where appropriate, inspect brushes on corded units, and replace worn bits promptly. Clear dust from vents and use battery care best practices for cordless models. Drill Bits Pro advises performing a quick functionality test after long sessions to detect any alignment or clutches issues early, which helps prevent costly repairs.

Expert tips from Drill Bits Pro

- Always wear eye protection and dust mask when drilling into masonry or concrete.

- Start with a smaller pilot hole to guide larger bits and reduce bit wandering.

- Use the correct bit type and anchor for the material to minimize hole flaws and improve holding power.

- For overhead drilling, turn on anti-vibration features and switch hands if possible to reduce fatigue.

- Regularly inspect the tool’s power cord or battery and maintain a clean, dry workspace to prevent accidents.

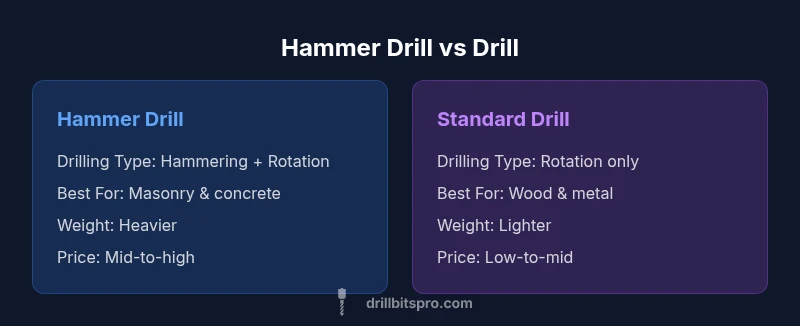

Comparison

| Feature | Hammer Drill | Standard Drill |

|---|---|---|

| Drilling Type | Hammering + Rotation | Rotational only |

| Best For | Masonry, concrete, brick | Wood, metal, plastics |

| Vibration & Noise | Higher vibration and noise | Lower vibration and quieter |

| Bit Compatibility | Masonry bits + standard bits | Standard twist bits only |

| Power & Torque | Greater torque and impact energy | Moderate torque and speed control |

| Weight | Heavier, longer sessions | Lighter and easier for extended use |

| Price Range | Mid-to-high | Low-to-mid |

| Best For Scenarios | Masonry drilling and heavy-duty tasks | General purpose drilling on wood/metal |

What's Good

- Expanded versatility for masonry and mixed-material projects

- Faster masonry drilling reduces project time

- Adjustable hammer modes improve control for different tasks

- Broad accessory and bit ecosystems support long-term use

Negatives

- Higher weight and bulk increases fatigue during long tasks

- Higher price and potentially greater bit wear with misuse

- Not ideal for precision drilling in metal unless equipped with appropriate bits

Hammer drills excel in masonry; standard drills excel in general-purpose tasks.

For masonry-heavy projects, a hammer drill with adjustable hammer action is typically the best choice. If your work is mostly wood or metal, a reliable standard drill delivers ease of use, lower cost, and precise control. Drill Bits Pro’s verdict favors selecting the tool that aligns with your core material focus and project duration.

Got Questions?

What is the difference between a hammer drill and a rotary hammer?

A hammer drill uses a hammering action to move the bit in and out while rotating, which helps with masonry. A rotary hammer delivers a more aggressive impact in a larger, piston-driven mechanism and is designed for heavy-duty concrete tasks. The drill is lighter and versatile, while the rotary hammer provides higher impact energy for tough jobs.

Hammer drills hammer while rotating; rotary hammers hit with greater force and are used for tough concrete tasks.

Can I use masonry bits in a standard drill?

Yes, it’s possible to use masonry bits in a standard drill, but performance will be limited and wear may increase. For concrete or brick, enable a hammer setting if available and proceed with caution. Always start slowly and use proper bit diameter and pressure.

Yes, but it’s not ideal for regular masonry work without hammer action.

Is a hammer drill necessary for DIY masonry?

For occasional masonry work, a corded hammer drill with masonry bits usually suffices. If you do frequent concrete drilling or heavy-duty tasks, a more powerful hammer or rotary hammer may be worthwhile. The choice depends on project frequency and material hardness.

If you drill masonry often, a hammer drill is helpful; for rare tasks, a standard drill with the right bits may suffice.

Are hammer drills louder or more tiring to use?

Hammer drills typically generate more vibration and noise than standard drills, which can increase fatigue during long tasks. Ergonomic design and anti-vibration features help, but expect higher fatigue in heavy-use scenarios.

Yes, more vibration and noise; choose ergonomics to mitigate fatigue.

What maintenance is needed for hammer drills and drills?

Keep vents clear, clean the chuck, and inspect bits for wear. For cordless models, monitor battery health and store charged. Periodically check brushes on corded units and lubricate moving parts per manufacturer guidance.

Clean, inspect, and follow the maker’s maintenance schedule.

Corded vs cordless: which should I choose?

Corded models offer unlimited runtime and consistent power for long masonry jobs, while cordless options provide portability for light, on-site work. If you value convenience and range, a cordless hammer drill with a spare battery is a strong option.

Corded is powerful, cordless is portable; pick based on task length and access to outlets.

Top Takeaways

- Assess material type first to guide tool selection

- Prioritize ergonomics for lengthy sessions

- Match bits to material and drill type

- Corded vs cordless should reflect runtime needs

- Prefer adjustable hammer modes for flexibility