Hammer Drill vs Regular Drill: An In-Depth Comparison

Analytical guide contrasting hammer drills and regular drills, detailing operation, use cases, bits, safety, and buying tips from Drill Bits Pro to help DIY enthusiasts and pros decide which tool to reach for.

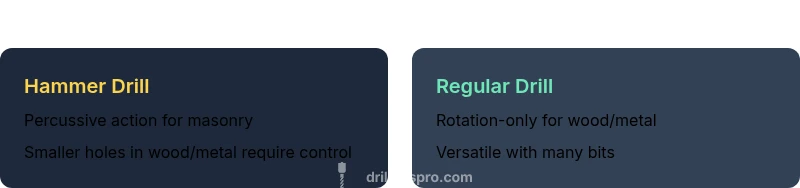

If you’re wondering what is a hammer drill vs regular drill, the quick answer is that the hammer drill uses a percussive impact in addition to rotation to bore into masonry, while a regular drill relies on rotation alone for wood, metal, and plastics. This concise comparison flags when to use each, the core differences, and what features to look for.

What is a hammer drill vs regular drill? Core concepts

What differentiates a hammer drill from a standard drill is the inclusion of an impact mechanism that delivers rapid, short impulses while the drill bit rotates. This percussive action helps the bit break through hard materials such as concrete and brick. In contrast, a regular drill relies on rotational motion alone, which is ideal for softer materials like wood and some metals. According to Drill Bits Pro, the distinction comes down to intended material and the resulting drilling action. Expect the hammer drill to feel slightly bulkier and louder during masonry work, while a regular drill offers smoother operation for fine, precise holes in wood and plastic. This first principle sets the stage for practical decision-making on the job site.

Mechanism and action: percussion vs rotation

Most hammer drills couple a motor-driven rotation with a tuned hammering action. When activated, the tool delivers tiny, rapid impacts that push the bit forward during masonry drilling. The impact is not a separate drill bit; rather, it works in concert with rotation to reduce bit resistance and minimize skidding. A regular drill lacks this pounding component, so masonry drilling relies solely on the bit’s cutting edge and the operator’s feed pressure. The result is slower progression in tough materials but highly controlled performance in softer substrates. The exact feel varies by model, but the fundamental physics remains consistent across brands.

When to use a hammer drill vs regular drill: practical job scenarios

Choosing between hammer and regular drilling comes down to material and the desired speed of progress. For masonry, concrete, and dense mortar, the hammer drill shines by driving through with controlled percussion. For framing, cabinetry, and woodworking, a regular drill provides clean holes and better edge quality. In mixed projects, many professionals carry both tools or a versatile model with adjustable hammering modes. The key is mapping job types to tool capabilities and avoiding over-penetration or overheating by using the correct mode for each task.

Bit types, chuck options, and compatibility

Bit compatibility plays a crucial role when choosing between a hammer drill and a regular drill. Hammer drills commonly accept larger bits suited for masonry, with some models using SDS or SDS-plus systems for rugged concrete work, while many standard drills use traditional twist bits for wood and metal. Chuck size, bit shank compatibility, and the ability to switch between hammer-on and hammer-off modes determine how smoothly you can transition between materials. Understanding these options helps you select the right bits and accessories, minimizing wear and maximizing hole quality.

Speed, torque, and control: expectations on the job

Perceived speed in each tool reflects not just RPM, but torque and the hammer action's effectiveness. A hammer drill typically offers adjustable speed and a clutch or torque-limiting mechanism to prevent bit grabbing when drilling masonry. Regular drills also feature speed controls but lack the hammering action, making them less aggressive on hard substrates. For users, this translates to smoother progress in wood and faster, more aggressive drilling in concrete when using a hammer mode. Mastery comes from practicing with the tool’s settings and selecting the proper bit and pressure for the material.

Safety and best practices: reducing risk on masonry and metalwork

Both tools require standard PPE—safety glasses, hearing protection, and dust masks where appropriate. When using a hammer drill, secure the workpiece and maintain a firm stance to counter the tool’s impulse. For delicate materials or thin walls, avoid over-penetration by using light pressure and the correct bit type. Regular drills should still employ a pilot hole when necessary and avoid forcing the bit beyond its design limits. Drill Bits Pro emphasizes moderation and technique to prevent bit failure and material damage.

Maintenance tips to extend life

Maintenance for both tool types includes keeping the chuck clean, lubricating moving parts as recommended by the manufacturer, and inspecting bits for wear. For masonry work, rinse dust from the vent areas and ensure vents are unobstructed to prevent overheating. If your hammer drill uses an SDS system, check the quick-release mechanism and replace worn components promptly. Regular drills benefit from bit care, correct storage, and periodic checks of the switch and trigger assemblies to maintain smooth operation.

Buying guide: features to prioritize for value

When shopping, prioritize a model with solid dust protection, reliable speed control, and a comfortable grip. For heavy masonry work, a hammer drill with robust percussion modes and a good chuck for larger bits is essential. If your project mix includes softer materials, a versatile drill with adjustable hammer modes and multiple speeds saves money and space. Compare weight, balance, and battery compatibility in cordless options to ensure you get the best value over time.

Real-world projects: cases and takeaways

In practical projects, the hammer drill’s efficiency shines on concrete walls and brick installations, while the regular drill excels in framing, shelf installation, and cabinetry. When confronted with tile anchors or masonry screws, a hammer drill reduces work time and improves consistency. For subtle drill operations on trim or faces, a regular drill with precise control is more suitable. Remember that the best approach often combines both tools in a single project for efficiency and quality.

Comparison

| Feature | Hammer Drill | Regular Drill |

|---|---|---|

| Primary function | Percussive drilling for masonry with rotation | Rotational drilling for wood, metal, and plastics |

| Best materials | Masonry, concrete, brick | Wood, metal, plastics |

| Materials handling | Eases penetration into hard substrates | Requires longer time and different bits for hard materials |

| Bit compatibility | Hammer-specific bits; can include SDS options | Standard twist bits; compatible with common drill bits |

| Weight/ergonomics | Typically heavier and more rugged | Lighter and more maneuverable for fine work |

| Price/value consideration | Generally higher upfront cost; higher utility for masonry | Lower cost; high versatility for small-to-medium jobs |

What's Good

- Excellent for masonry and concrete projects

- Faster hole progression in hard materials

- Versatile in mixed-duty roles with adjustable modes

- Widely available with cordless options and accessories

Negatives

- Higher purchase price and bulk

- Bit and accessory costs can accumulate

- Requires more maintenance and care in dust-heavy tasks

- Potential for bit wandering if not properly stabilized

Hammer drills excel for masonry; regular drills cover most non-masonry tasks

For masonry-focused work, the hammer drill is the clear winner due to its percussive action. For woodworking and general-purpose drilling, a regular drill remains the versatile choice. The Drill Bits Pro team recommends pairing both tools for the broadest capability, or choosing a high-quality multi-mode model if you frequently encounter mixed material tasks.

Got Questions?

What is the main difference between hammer drill and regular drill?

The hammer drill combines rotation with a percussive action to drive through masonry, while a regular drill relies on rotation alone for holes in softer materials. This percussive mechanism is the key differentiator and determines the best use cases.

The main difference is the hammer action combined with rotation versus rotation alone.

Can I use standard drill bits in a hammer drill?

Yes, for many hammer drills you can use standard twist bits for wood and metal, but masonry bits are needed for concrete. Check your model’s chuck compatibility and switch bits as needed.

Yes, but you may need masonry bits for concrete.

Is a hammer drill necessary for concrete projects?

For most concrete projects, a hammer drill speeds up drilling significantly because of its percussive action. If you only drill through wood or metal, a regular drill is typically sufficient.

For concrete, a hammer drill is usually the better choice.

Are cordless hammer drills worth it for DIY tasks?

Cordless hammer drills offer portability and convenience for light-to-moderate masonry work. For heavy-duty concrete or long sessions, a corded model or higher-capacity battery may be preferable.

Cordless is convenient, but may have runtime limits for heavy jobs.

Can I convert a regular drill into a hammer drill?

Most regular drills cannot be converted into hammer drills. Some models have a hammer function, but if your tool lacks it, you’ll need a dedicated hammer drill or a hybrid model with adjustable modes.

You typically can’t convert a regular drill into a true hammer drill.

What safety gear should I use with hammer drills?

Wear safety glasses, hearing protection, and a dust mask when needed. Secure workpieces and maintain a firm grip to manage the tool’s impulse during masonry drilling.

Safety basics: glasses, ears, and mask when needed.

Top Takeaways

- Identify your primary material (masonry vs wood/metal).

- Choose hammer drill for concrete, regular drill for everyday tasks.

- Prioritize variable speed, clutch, and bit compatibility.

- Consider weight and ergonomics for extended use.

- Plan for accessories and battery compatibility in cordless setups.