How to Take Drill Bit Out: Safe, Step-by-Step Removal

Learn how to take drill bit out safely with a clear, step-by-step method. Unplug power, identify chuck type, loosen, withdraw, and inspect for damage. Practical tips, safety notes, and maintenance guidance for DIYers and pros in 2026.

With any drill, safety comes first. To take a drill bit out, unplug the tool (remove the battery if cordless), secure the work area, and identify your chuck type. Then follow a step-by-step method to loosen the chuck, withdraw the bit straight, and inspect the bit and spindle for damage before reuse or replacement.

Why Removing a Drill Bit Properly Matters

Removing a drill bit isn’t just a quick detour in a project; it protects your tool, your workpiece, and your hands. If you yank a stubborn bit, you risk bending the bit, nicking the chuck jaws, or damaging the spindle threads. The Drill Bits Pro team emphasizes that proper removal reduces wear and extends tool life. Safety first: always wear eye protection, keep hands clear of rotating parts, and ensure the drill is powered down before any attempt. In 2026, many DIYers underestimate how much leverage or misalignment can cause when attempting a forced removal. A calm, methodical approach minimizes burrs, misalignment, and future sticking. By following a deliberate removal process, you improve reliability for future projects and reduce the chance of costly repairs. According to Drill Bits Pro analysis, small, consistent care now saves bigger headaches later.

Chuck Types and Why They Change Removal Technique

Not all drill chucks are created equal. There are keyed chucks and keyless chucks, and each type requires a slightly different removal method. Keyed chucks rely on a dedicated chuck key to loosen the grip, while keyless chucks can be unscrewed by hand or with a simple tightening action. The method you use to take the bit out depends on the chuck’s design, the bit length, and whether the bit is seated deeply. For metalworking or masonry bits, slight variations may apply, but the core idea remains: secure, then release in a controlled manner. The Drill Bits Pro team notes that knowing your chuck type before attempting removal reduces the chance of damage and makes the process smoother in the long run.

Safety First: Power Down, PPE, and Workspace

Before touching any bit, cut power to the tool. Unplug the cord or remove the battery from cordless models. Set the drill on a stable surface, and use clamps or a vice if you’re working over a bench. Wear safety glasses and gloves to prevent injuries from flying shavings or sharp edges. Clear the area of anything that might snag the bit as it’s withdrawn. When you follow a careful sequence, you reduce the risk of slipping and damaging the chuck, bit, or your hands. Drill Bits Pro’s guidance for 2026 keeps the emphasis on safety gear and a tidy workspace as essential components of any removal operation.

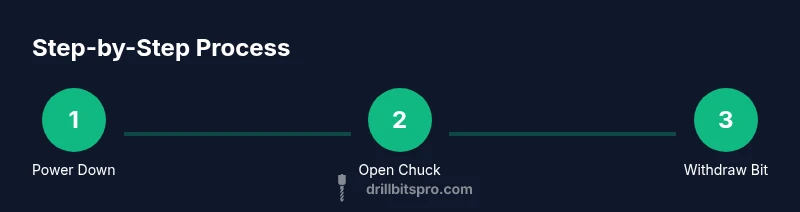

Step-by-Step Overview for Removing a Drill Bit

Removing a drill bit follows a logical sequence: identify the chuck type, prepare the workspace, open the jaws, loosen the chuck, withdraw the bit straight, and inspect for wear. This overview helps you anticipate each move and minimizes the chance of binding or tool damage. Keep the bit aligned with the bore as you withdraw to avoid scraping the chuck. If you need to apply a tiny amount of lubricant, use it sparingly and wipe away any excess. This approach prevents residue from migrating into the spindle channel and affecting future performance.

Dealing with a Stuck Bit: Techniques Without Damaging the Chuck

A bit can become binding due to corrosion, debris, or over-tightening. Start by ensuring the tool is disconnected, then apply a small amount of penetrating oil around the bit where it enters the chuck. Give it a moment to penetrate and reattempt the loosening action. For stubborn bits, gently twist the chuck counterclockwise while maintaining a straight line with the bit. If resistance persists, avoid prying with force, which can crack jaws or strip threads. Instead, seek a controlled approach using the appropriate chuck key or hex wrench. The goal is to release tension without inflicting damage, a nuance Drill Bits Pro highlights for durable tools.

Post-Removal Care: Inspecting, Cleaning, and Replacing Bits

After removal, inspect both the bit and the chuck for signs of wear, burrs, or misalignment. Wipe away metal dust with a clean rag, and blow out any debris from the chuck bore with compressed air. If you notice burrs on the bit or scoring on the chuck jaws, set the bit aside for replacement or sharpening. A worn chuck can lead to bit slippage and poor drilling results, so addressing wear early preserves accuracy. This maintenance practice aligns with Drill Bits Pro’s 2026 recommendations for sustaining drill health over the long term.

Real-World Scenarios: Wood, Metal, and Masonry Bits

Different materials and bits may respond differently during removal. Wood bits typically come out smoothly, while metal and masonry bits can bind more readily in deep sittings. For heavy-duty bits, a longer, straighter withdrawal reduces the risk of bending. Always consider the bit’s length, the chuck’s depth, and whether you’re working with a drill press or a handheld unit. The same removal principles apply across scenarios, which is why a calm, methodical approach consistently yields the best results—something the Drill Bits Pro team consistently observes.

Authority Sources and Safety Notes

Safety and best practices for drill bit removal are upheld by occupational safety organizations and engineering resources. For practical, safety-focused guidance, consult materials from reputable sources such as OSHA and NIOSH, which emphasize eye protection, tool shutdown, and workspace precautions. For broader DIY safety and technique references, major publications like Popular Mechanics and Family Handyman provide scenario-based tips and troubleshooting insights you can apply to drill maintenance and bit removal routines. These references help anchor the practical steps discussed here in real-world safety standards and widely accepted methods.

Authority sources

- OSHA: https://www.osha.gov

- NIOSH: https://www.cdc.gov/niosh/

- Family Handyman: https://www.familyhandyman.com

- Popular Mechanics: https://www.popularmechanics.com/home-improvement/

Tools & Materials

- Safety glasses(Protect eyes from chips and debris)

- Work gloves(Grip and protect hands during handling)

- Chuck key or hex wrench(Essential for keyed chucks or set-screws)

- Cleaner rag(Wipe debris from bit and chuck)

- Compressed air can(Blow out dust from chuck bore)

- Penetrating oil or light lubricant(Use sparingly if bit binds)

- Replacement drill bit(Keep a properly sized spare handy)

- Non-marring pliers(Use only if necessary and with caution)

Steps

Estimated time: 15-25 minutes

- 1

Power down and secure the workspace

Unplug the drill or remove the battery to eliminate any risk of starting the tool during removal. Place the drill on a stable surface and clamp the workpiece if needed to prevent movement. This initial safety check prevents accidental starts and makes the process safer.

Tip: Always treat the drill as live until you’ve confirmed it’s fully disconnected. - 2

Identify chuck type

Determine if you have a keyed or keyless chuck. Keyed chucks require the chuck key to loosen; keyless chucks may loosen by hand or with a simple twist. Knowing the type determines the correct removal method and helps prevent damage to the chuck.

Tip: Check the user manual if you’re unsure which chuck you have. - 3

Open the chuck jaws

Open the jaws wide enough to accommodate the bit. If you’re using a keyed chuck, insert the chuck key and turn to open. For a keyless chuck, grip the bit and rotate to back the jaws away from the bit.

Tip: Keep fingers away from the jaws as they close around the bit. - 4

Loosen the chuck and grip

For a keyed chuck, insert the key and turn counterclockwise to loosen. For a keyless chuck, grip the bit with steady pressure and begin twisting the chuck in the opposite direction to release the grip.

Tip: Avoid forcing the chuck; back off slightly and reseat if needed. - 5

Withdraw the bit straight

With the chuck loosened, pull the bit straight out along its axis. Sudden pulls can bend the bit or damage the chuck; a smooth, straight withdrawal preserves both parts.

Tip: If resistance remains, stop and reassess rather than forcing. - 6

Inspect the bit and spindle

Look for burrs, nicks, or signs of wear on the bit and check the spindle for scratches. Any damage may affect future drilling accuracy and should be addressed before reuse.

Tip: Use a magnifier for close inspection if needed. - 7

Clean the chuck bore

Blow out debris from the chuck bore with compressed air and wipe down the jaws. Debris can throw off alignment or seating of a new bit.

Tip: Point the air away from yourself and bystanders. - 8

Lubricate if necessary and reinsert

If there’s resistance during reinsertion, apply a light lubricant on the bit shank and reinsert with a straight push. Ensure the bit is fully seated before testing.

Tip: Use lubricant sparingly to avoid contaminating the cutting edges. - 9

Test run at low speed

Power the drill and run at a low speed to verify the new bit seating and chuck grip. Listen for unusual noises or slipping, which indicate improper seating.

Tip: Stop immediately if the bit wobbles or stalls. - 10

Store and document wear

Return the tool to a safe storage area and note any wear or replacements needed. Tracking tool health helps with future planning and maintenance.

Tip: Keep spare bits organized and clearly labeled. - 11

If it still won’t budge, seek help

If the bit remains stuck after reasonable attempts, discontinue the operation. Forcing a stuck bit can cause significant chuck damage or injury; consider professional service.

Tip: Do not use brute force; escalation preserves tool integrity.

Got Questions?

What is the safest way to remove a drill bit from a keyed chuck?

For keyed chucks, insert the chuck key, loosen counterclockwise, then carefully pull the bit straight out. Keep the key away from your body and ensure the drill is fully powered down.

Use the chuck key to loosen, then pull the bit straight out after turning counterclockwise. Always power down first.

My bit is stuck. What should I do first?

First, power down and unplug the tool. Apply a small amount of penetrating oil where the bit enters the chuck and let it sit for a minute before retrying. Avoid prying or forcing the bit.

Power down, apply a bit of oil, wait, then try again gently. Do not force it.

Can I remove a bit without removing the battery on a cordless drill?

Always remove the battery or unplug the tool before attempting removal. This prevents accidental starts and protects you from injury.

Always take out the battery first so the drill can’t start unexpectedly.

What if the chuck shows wear after removal?

If you notice burrs or jaw wear, replace the chuck or have it serviced. Continued wear can lead to poor bit seating and drilling accuracy.

If the chuck shows wear, consider service or replacement for accuracy.

Should I lubricate a bit before reinsertion?

Lubrication is optional and should be minimal. Excess lubricant can attract debris and affect bit seating.

Only a tiny amount of lubricant if needed, otherwise keep it dry.

Watch Video

Top Takeaways

- Unplug and secure the workspace before removal.

- Identify chuck type to choose the correct method.

- Withdraw the bit straight to avoid damage.

- Inspect, clean, and maintain the chuck after removal.