How to Tell Drill Bits Apart: A Practical Guide

Learn how to tell drill bits apart by shank, tip, material, and markings. A practical, step-by-step approach for DIY enthusiasts and pros to identify wood, metal, masonry, and specialty bits with confidence.

This guide teaches you how to tell drill bits apart by analyzing shank shape, tip geometry, and material. You’ll learn to identify common bit families (wood, metal, masonry), read size markings, and differentiate coatings. By the end, you’ll be able to sort, select, and organize drill bits quickly and confidently.

What is a drill bit, and why identification matters

Drill bits are small cutting tools that come in a surprising variety of shapes, shanks, coatings, and materials. The way a bit is built determines which materials it can cut, how clean the hole will be, and how long the bit will last under load. For DIY enthusiasts and professionals, being able to tell drill bits apart means faster setup, safer work, and fewer ruined projects. The vocabulary is useful: shank, flute, tip, material, and coating. Start by recognizing that most bits fall into broad families (wood, metal, masonry), then refine your knowledge by inspecting shank shape, tip geometry, and any markings on the bit. This knowledge pays off every time you pick the right bit for the job.

Establishing a baseline: why identification matters for your toolkit

When you know how to distinguish bits, you can avoid using a wood bit on metal, or a masonry bit on wood, which can crack, dull, or break both the bit and the workpiece. Proper identification also helps with compatibility: your drill’s chuck size and the bit shank must fit together. Finally, correct identification supports safer handling and storage, reducing the risk of accidental starts or misalignment during operation.

Quick identifiers you’ll use

- Shank shape: round, hex, or SDS for hammer drills

- Tip style: twist, brad-point, masonry, or specialized tips

- Material/coating: high-speed steel (HSS), cobalt, carbide, or coatings like black oxide or TiN

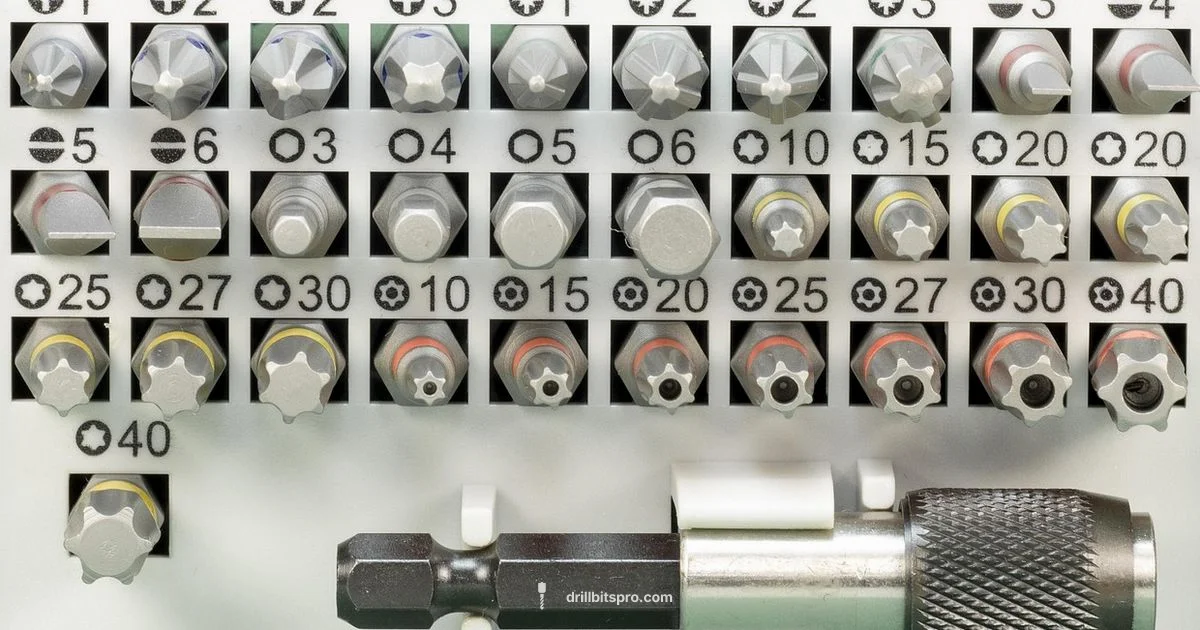

- Markings: size, length, and manufacturer stamps (when present)

- Color codes: not universal, but can hint at coating or material in some brands

Keep this in mind as you move through the guide: you’re building a mental map that helps you instantly classify bits when you pick them up.

How this guide is organized

The sections that follow will help you identify shank shapes, tip geometries, materials and coatings, how to read markings, and a practical field workflow. You’ll also find common mistakes to avoid, maintenance and labeling tips, a quick-start checklist, and a short FAQ to cover questions that come up in real projects. By the end, you’ll be able to tell drill bits apart with practical, repeatable steps.

Brand context and practical usefulness

According to Drill Bits Pro, mastering bit identification reduces downtime and increases success rates on DIY and professional projects. This guide translates that expertise into actionable steps you can apply on any job site. Whether you’re building a cabinet, drilling pilot holes in hardwood, or chasing fasteners in masonry, the ability to distinguish bits quickly will save you time and frustration.

Tools & Materials

- Caliper or digital micrometer(Used to measure shank and flute diameters precisely)

- Magnifying loupe or jeweler’s loupe(Magnifies markings on the bit for easy reading)

- Sharpie or labeling tape(Label bits after identification to prevent mix-ups)

- Size gauge or drill bit size chart(Helps correlate markings to actual diameters)

- Scratch pad and pencil(Note down findings for quick reference)

- Safety gear (goggles, gloves)(Protect eyes from sharp edges and chips)

- Scrap material for testing(Optional; verify cutting behavior before use on a real piece)

Steps

Estimated time: Estimated total time: 20-30 minutes

- 1

Inspect the shank

Begin by looking at the shank—the part that fits into the drill chuck. Round shanks are common for handheld drills, hex shanks fit quick-change chucks, and SDS shanks are designed for hammer drills. This initial assessment narrows your options before you even check the tip.

Tip: If in doubt, test-fit with the drill’s chuck open to confirm compatibility before applying any pressure. - 2

Examine the tip geometry

Next, examine the tip. Twist bits have a helical flute and a point; brad-point bits have a central point with spurs for clean wood holes; masonry bits have a carbide tip and a short, robust flute; specialty bits (step bits, spade bits) have distinctive shapes tailored to specific tasks.

Tip: Handle brad-point tips gently to avoid dulling the spurs during inspection. - 3

Check material and coatings

Identify the base material (HSS, cobalt, carbide) and any coatings (black oxide, TiN). Coatings influence wear resistance and heat tolerance, while the core material indicates best-use scenarios. This helps you predict performance and longevity.

Tip: Remember: coatings are not universal; refer to manufacturer data when possible. - 4

Read the markings

Read any numbers or letters on the flute or shank. Markings usually indicate diameter, length, and sometimes a batch or part number. If markings are faded, use a loupe or caliper to compare to a known size chart.

Tip: Markings can be size-inconsistent across brands; always confirm with a measurement tool. - 5

Cross-check against your job type

Match the bit family to the job: wood bits for wood, metal bits for metal, masonry bits for concrete. This quick sanity check prevents mistakes before you drill.

Tip: If you’re unsure about the material, test on a scrap piece first. - 6

Label and store

Label each identified bit with its diameter and intended material. Store bits in clearly labeled trays or organizers to avoid future misidentification.

Tip: Group similar bits together and keep protection caps on for safety. - 7

Confirm with a quick test

If possible, perform a light test cut on scrap material to verify the bit’s performance and hole quality before proceeding with the final work.

Tip: Avoid forcing the bit; let the cutting edge do the work at an appropriate speed. - 8

Document your findings

Record outcomes and any notes about how the bit behaved under load. This helps you remember preferences for future projects and builds a personal database.

Tip: A simple notebook or digital note works; consistency matters. - 9

Review safety and maintenance

Close the loop by inspecting your bits for wear, re-sharpen if needed, and check chuck compatibility before the next use. Proper maintenance reduces misidentification risk and extends life.

Tip: Never reuse damaged bits; replace worn edges to maintain accuracy.

Got Questions?

What is the difference between a twist bit and a brad-point bit?

Twist bits are general-purpose for wood and metal with spiraling flutes. Brad-point bits have a central point and spurs for clean wood holes. The choice depends on the desired hole quality and material.

Twist bits are general-use, while brad-point bits give clean wood holes with a central point and spurs.

How can I tell if a bit is SDS or standard round shank?

SDS shanks are designed for hammer drills and have a broader, grooved profile, often with a distinctive end. Round shanks fit typical chucks. Try to insert the bit into the drill; if it’s hard to insert or won’t seat, it’s likely SDS or a non-round shank.

SDS shanks fit hammer drills and have a grooved profile; round shanks fit standard chucks.

Why do some bits have color coatings?

Coatings like black oxide or TiN improve wear resistance and reduce friction. They don’t guarantee performance in all materials, so rely on the core material for the best guidance.

Coatings help wear resistance but aren’t a universal performance guarantee.

Do all drill bits have universal sizes?

No. Sizes are standardized but can vary by brand. Always verify with a size chart or calipers when in doubt.

Sizes vary by brand; always confirm with a caliper or size chart.

How do I maintain drill bits to prevent dulling?

Keep bits clean, store properly, and avoid overheating by using appropriate speeds and feeds. Regularly sharpen or replace dull bits to maintain accuracy.

Keep bits clean, avoid overheating, and sharpen or replace dull bits as needed.

What’s the best way to label drill bits?

Label by diameter and material use, and store in dedicated compartments. Clear labeling reduces misidentification during busy projects.

Label by size and use, and store in dedicated compartments.

Watch Video

Top Takeaways

- Identify shank first to narrow options

- Match tip type to material for correct use

- Read markings and verify with measurement

- Label and organize bits for quick access