Can Drill Bits Go Through Metal? A Practical Guide

Discover how drill bits can cut through metal, choose the right bit, and master speeds, lubrication, and safety for metals like aluminum, mild steel, and stainless.

With the right bit, speed, and lubrication, drill bits can go through metal. This quick guide highlights how bit material, metallurgy, and technique determine success across aluminum, steel, and tougher alloys. Follow practical steps to drill through metal reliably, whether you’re a DIYer or a professional.

How metal drilling works: heat, metallurgy, and cutting action

According to Drill Bits Pro, drilling through metal is a balance of physics, material science, and technique. When the cutting edge meets metal, it shears material away, forming chips that must evacuate the hole. The process generates heat from friction, and metal alloys respond differently: some soften briefly, others resist cutting and heat buildup. If heat isn’t controlled, the edge dulls, work hardening can occur, and the hole may wander. The practical takeaway is simple: use a sharp bit, secure the workpiece, and manage heat with lubrication and deliberate feed pressure. Even with soft aluminum, you still need a plan to prevent wandering and overheating and to ensure a clean exit for chips. If done correctly, you can drill through metal with predictable results, from basic aluminum to thicker steel, as long as you respect material properties and implement steady technique.

Choosing the right bit for metal

Metal drilling relies on bit geometry and material. High-speed steel (HSS) bits work for softer metals and light-duty jobs, but harder alloys demand tougher options. For stainless steel or hardened steel, consider cobalt or carbide-tipped bits; these materials resist destruction at higher temperatures and maintain edge sharpness longer. Coatings like titanium nitride can reduce wear and help with heat management, especially on repeated tasks. When you ask, can drill bits go through metal, the short answer is yes—with the right bit type, a clean starting point, and a controlled cutting process. The key is matching material properties to bit design and avoiding overly aggressive feeds that cause heat spikes and bit chipping.

Speed, feed, and lubrication basics for metal

Lubrication is not optional; it dramatically reduces heat and decreases bit wear. Use cutting oil or light mineral oil and apply sparingly to the cutting edge. The speed (RPM) and feed (pressure) must be balanced: too fast or too hard and the bit overheats; too slow and you risk rubbing instead of cutting. For most metals, begin at a modest speed and adjust based on feedback—if chips are long and curling, you’re in a good range; if the bit glows or smoking starts, slow down and apply more lubricant. Remember, can drill bits go through metal when you slow down and use lubrication? Yes—and you’ll produce cleaner holes with less effort. If you’re drilling multiple holes, pause to cool and wipe away chips between holes to maintain edge quality.

Common metal types and how they affect drilling

Not all metals behave the same. Aluminum is relatively soft and forgiving but can seize if the bit is not sharp or there’s insufficient lubrication. Mild steel is tougher but responds well to standard HSS bits with proper lubrication and moderate speeds. Stainless steels and other hard alloys resist cutting and heat more quickly, so you’ll want cobalt or carbide bits and slower speeds. Cast iron behaves differently—watch for chip formation and ensure the workpiece is well supported. Understanding these differences helps you answer the question can drill bits go through metal in a controlled way, avoiding dulling and exit burrs.

Practice tips and safety considerations

Preparation matters as much as the drill itself. Clamp the workpiece securely, mark the hole with a center punch to create a starting point, and confirm bit diameter matches your hole target. Always wear safety glasses and gloves, and keep your hands away from the rotating bit. Deburr the hole after drilling to prevent injuries and reduce stress on the edge. If you’re new to drilling through metal, practice on scrap pieces first and gradually increase hole size while maintaining control over speed and pressure.

Tools & Materials

- Drill with variable speed control(Chuck accepts bit shanks; use moderate, controllable RPM.)

- HSS drill bits for metal(Choose sizes with a 135-degree point for starting accuracy.)

- Cobalt or carbide-tipped drill bits(Use for hard metals like stainless steel or hardened alloys.)

- Center punch and hammer(Create a small dimple to guide the bit.)

- Clamps or a vise to secure the workpiece(Prevents movement and slipping.)

- Lubricant (cutting oil or light mineral oil)(Heat management and edge longevity.)

- Marker or scribe for hole location(Ensure hole center is accurate.)

- Safety glasses and gloves(Protect against metal chips and sharp edges.)

- Drill press (optional)(Improves accuracy for straight holes.)

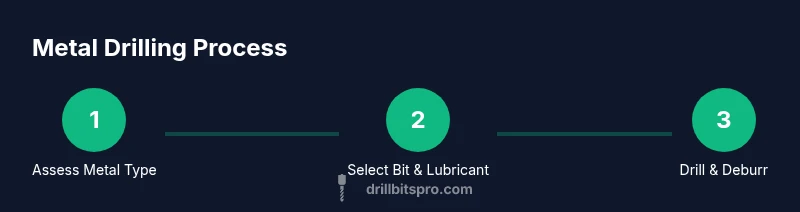

Steps

Estimated time: 30-45 minutes

- 1

Prepare and mark the workpiece

Position the workpiece and mark the hole location with a center punch. This creates a small dimple that guides the bit and reduces wandering.

Tip: Use a sharp punch and a light hammer strike to create a crisp indentation. - 2

Secure the workpiece

Clamp the material firmly to a stable surface or workbench. Movement during drilling is a common cause of off-center holes.

Tip: Double-check clamps before starting; two-point contact minimizes vibration. - 3

Choose bit and apply lubrication

Select the appropriate bit for the metal type and apply a thin lubricant to the cutting edge. Lubrication transfers heat away and reduces wear.

Tip: If cutting aluminum, a sharper edge and light oil help prevent gleaming or grabbing. - 4

Start with a pilot hole

Drill a small pilot hole to guide the larger bit. A pilot hole reduces stress and improves accuracy on harder metals.

Tip: Keep the drill perpendicular to the surface to prevent drift. - 5

Drill to final size with steady feed

Switch to the final bit, maintain steady pressure, and let the bit cut at a comfortable pace. Withdraw occasionally to clear chips.

Tip: Avoid forcing the bit; let the edge do the work. - 6

Deburr and inspect

Remove burrs with a deburring tool or file and inspect the hole for alignment and edge quality. Clean the surface after finishing.

Tip: Deburring prevents injuries and reduces stress concentrations.

Got Questions?

Can any drill bit drill through metal or are specialized bits required?

Not all bits are suitable for metal. Use bits designed for metal, such as HSS, cobalt, or carbide-tipped bits, and apply lubrication to manage heat. The tool choice depends on metal hardness and thickness.

Not all bits are suitable for metal. Use metal-rated bits with lubrication to manage heat.

Is drilling aluminum easier than drilling stainless steel?

Yes, aluminum is generally easier to drill than stainless steel due to its softness. Stainless steel requires tougher bits and slower speeds, along with adequate lubrication.

Aluminum is easier to drill; stainless steel needs tougher bits and careful cooling.

Do I need a pilot hole when drilling metal?

A pilot hole guides the larger bit and reduces heat buildup. Start with a smaller bit to create a precise starting point.

Yes, start with a pilot hole to guide the larger bit.

What safety gear should I wear when drilling metal?

Wear safety glasses to protect eyes from chips and gloves to protect hands. Use ear protection if the work is loud and secure clothing to prevent tangling.

Wear safety glasses and gloves, and keep loose clothing away from the drill.

Can I drill through stainless steel with a standard HSS bit?

Stainless steel is harder; it’s best to use cobalt or carbide bits and slow, steady feeds with ample lubrication to prevent excessive heat.

Stainless steel needs cobalt or carbide bits and careful cooling.

What should I do if the bit overheats or dulls quickly?

Stop drilling, remove heat with cooling lubricant, and switch to a sharper bit or a tougher material. Avoid forcing the bit through and give it time to cool.

If it overheats, cool the edge and switch to a sharper bit.

Watch Video

Top Takeaways

- Choose metal-appropriate bits (HSS, cobalt, or carbide).

- Secure the workpiece and mark starting points precisely.

- Lubricate and control speed to minimize heat and wear.

- Start with a pilot hole for accuracy.

- Deburr holes for safety and longevity.