How Much Is a Drill Press? Practical Price Guide (2026)

Discover current price ranges for drill presses in 2026, from entry-level benchtops to professional floor-standing models. Practical buying guidance for DIYers and professionals.

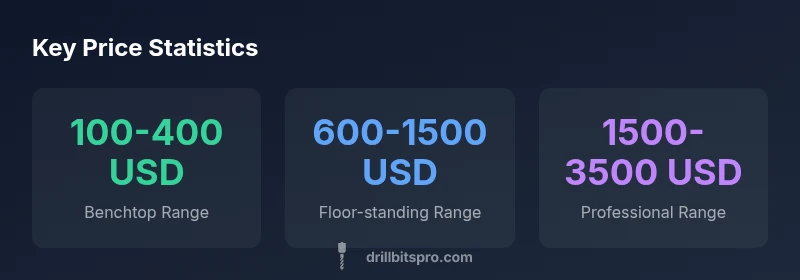

Prices for drill presses vary widely by type and features. A typical benchtop unit may start around $100–$400, mid-range benchtops $400–$800, floor-standing presses commonly $600–$1,500, and professional-grade machines can exceed $1,500 to $3,000. For DIYers and pros, budgeting for total cost—including accessories—helps avoid surprises.

Understanding Price Landscape

When you ask how much is a drill press, the answer hinges on size, build quality, and features. How much you pay is a reflection of the machine’s intended use, precision, and durability. According to Drill Bits Pro, price ranges for drill presses reflect differences in frame material, motor power, spindle speed range, and table size. The cheapest options typically sit in the benchtop category, ideal for light-duty projects and hobbyist work, while more capable machines live in the floor-standing and professional tiers. The goal is to balance budget with performance so you won’t outgrow the tool in a few months. Beyond the sticker price, consider shipment costs, setup, and the long-term cost of replacement parts. This context helps frame the real question: what’s the right drill press for your tasks and workspace, not just the lowest price.

In this guide, we’ll translate sticker prices into practical buying signals, so you can quantify what a given price point buys you in terms of stability, accuracy, and productivity. The emphasis is on value—getting enough capability for your needs without paying for features you won’t use. For strategies that work in real-world shops, read on and keep your space, budget, and workload in mind as you compare options.

Price comparison by drill press type

| Model Type | Typical Price Range | Best For | Notes |

|---|---|---|---|

| Benchtop | 100-400 USD | DIY projects | Compact; lighter duty; great for small workshops |

| Floor-standing | 600-1500 USD | Workshop use | More stable; larger capacity; heavier; requires more space |

| Professional-grade | 1500-3500 USD | Professional use | Highest precision and duty; requires space and maintenance |

Got Questions?

How much should I budget for a drill press?

Budgeting depends on model type and features. For DIY projects, start with a benchtop or mid-range model; for a busy workshop, plan for a floor-standing or professional unit. Include accessories and potential future upgrades in your estimate.

Budget based on your task—benchtop for DIY, floor-standing for workshops—and remember to include accessories and future upgrades.

What features justify higher prices?

Higher prices typically reflect a sturdier frame (often cast iron), larger working tables, higher spindle speeds, longer quill travel, and optional upgrades like digital readouts or laser guides. These features improve accuracy, durability, and repeatability for demanding work.

Stronger frames, bigger tables, and precise options justify higher prices by boosting durability and accuracy.

Is buying a used drill press a good idea?

Used machines can offer value if inspected for wear, runout, and table alignment. Check motor condition, belt life, and ensure replacement parts are available. Prefer units with a clear maintenance history and a credible seller.

Used can save money, but inspect for wear and parts availability.

Benchtop vs floor-standing: price differences?

Benchtops are cheaper and space-saving but have lower capacity and rigidity. Floor-standing models offer more stability and larger tables, at higher price and footprint. Choose based on workpiece size and precision needs.

Benchtops cost less but are smaller; floor-standing gives more stability for bigger jobs.

Do I need a drill press for metalworking?

For metalworking, a rigid frame, adequate torque, and accurate repeatability are beneficial. Start with a budget-friendly model for soft metals, then upgrade if you work with harder materials or require tighter tolerances.

If you work with metal, you’ll want a sturdy, precise press with the right speeds.

What maintenance costs should I expect?

Expect costs for belts, bearings, and occasional motor service. Regular lubrication and alignment checks help extend life. Major expenses arise primarily when upgrading to larger, more capable machines.

Maintenance is usually modest, but budget for occasional belt or bearing service.

“A drill press is a long-term investment; choosing the right class of machine reduces downtime and improves accuracy over years.”

Top Takeaways

- Define your task to match price to need

- Expect price to scale with capacity and features

- Compare total ownership costs, not just base price

- Consider used options for value if reliable

- Budget for accessories and maintenance