What Drill Bits Go Through Metal: A Practical Guide

Learn which drill bits cut through metal, when to choose HSS, cobalt, or carbide, and how to drill stainless steel, aluminum, and steel safely with expert guidance from Drill Bits Pro.

To drill through metal, choose drill bits designed for metalworking—HSS for softer alloys, cobalt or carbide-tipped bits for tougher steels such as stainless. Always start with a center punch to guide the bit, apply light lubrication to reduce heat, and use a slow, steady feed. If the metal is very hard, pause to clear chips and maintain even pressure to prevent blueing or breakage.

Metal drilling essentials: choosing the right bits

When you need to penetrate metal, the first decision is selecting the right drill bit. According to Drill Bits Pro, the best outcomes come from using bits specifically engineered for metalworking, not wood or masonry bits. Start with common metalworking bits like High-Speed Steel (HSS) for softer metals, and keep cobalt- or carbide-tipped variants on hand for harder alloys. The material choice influences heat resistance, wear life, and the hole diameter you can achieve. Remember that even the best bit can fail if the setup isn’t secure or the bit isn’t appropriate for the metal’s hardness and thickness.

Why metal-only bits matter for durability and finish

Metal has different mechanical properties than wood or plastic, including hardness, heat generation, and chip formation. Using the wrong bit can dull quickly, cause heat build-up, or wander off the mark. HSS bits are a good starting point for mild steel and aluminum, but stainless steel and heat-treated alloys demand more robust options like cobalt or carbide. Coatings such as titanium nitride can reduce wear but do not compensate for poor technique. Precision and patience pay off with smoother holes and less tool wear.

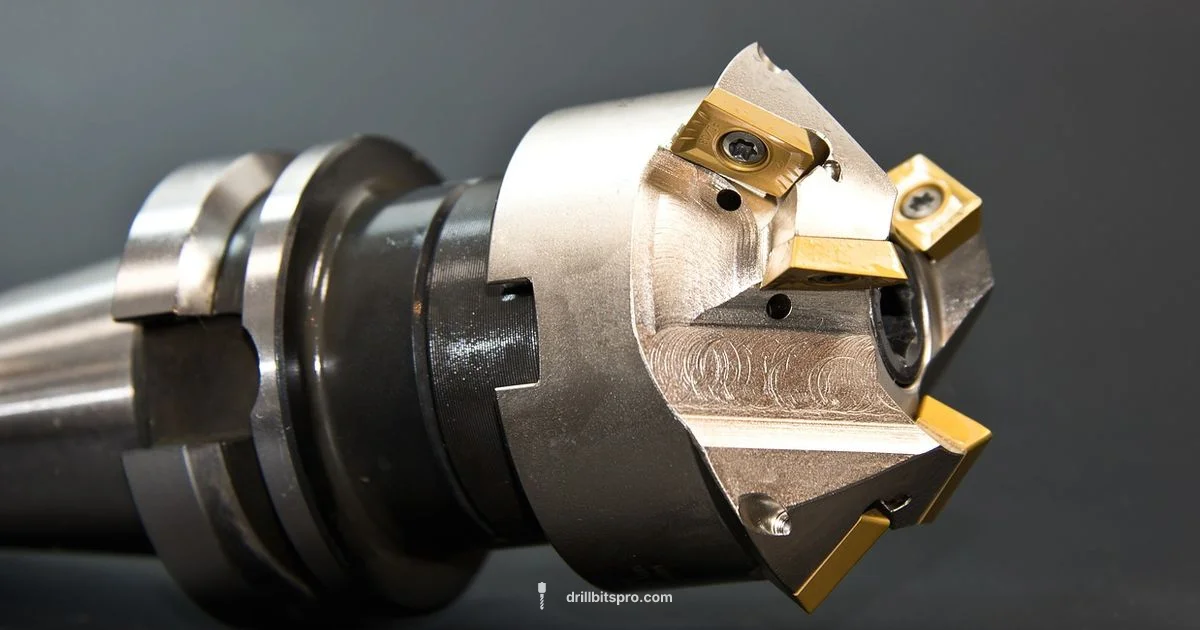

Bit options: HSS, cobalt, and carbide compared

High-Speed Steel (HSS) bits are versatile and economical for everyday metalwork, especially thinner stock or softer metals. Cobalt bits, typically containing 5-8% cobalt, excel at higher heat tolerance and maintain sharpness longer in harder metals. Carbide-tipped bits resist wear extremely well, ideal for repeated drilling into stainless steel or hardened alloys, but they are more brittle and costly. For thin gauge metals or occasional work, HSS suffices; for production or demanding metals, consider cobalt or carbide-tipped designs. Drill Bits Pro notes that a balanced toolkit often includes at least one HSS bit for general use and a cobalt bit for tougher jobs.

Geometry and coatings: what to look for

Bit geometry matters as much as material. A sharp point angle and a few flute edges help cut metals cleanly and manage heat. Split-point designs improve starting accuracy, reducing wandering on hard surfaces. Coatings like titanium nitride (TiN) or black oxide reduce friction and extend life, but the base material and geometry determine performance most. For stainless steel and hard alloys, prioritize tougher substrates (cobalt or carbide) and appropriate geometry to maintain a true, straight hole.

Preparing the workpiece and tools

Secure the workpiece firmly using a bench vise or clamps so it doesn’t shift when the bit penetrates. A center punch creates a small dent that guides the bit and reduces walking on hard metal. Apply a light lubricant or cutting oil to minimize heat and chip welding. Have spare bits and a method for clearing chips nearby; metal drilling generates expelled material that can recut or re-weld against the bit if not cleared. A clean, well-prepared setup saves time and reduces the risk of bit breakage.

Drilling technique for different metals

Steel, aluminum, and stainless steel require distinct approaches. Aluminum is softer and heats quickly but chips easily; keep feed light and coolant or oil to prevent galling. Mild steel accepts faster feeds but still benefits from lubrication and pecking to clear chips. Stainless steel is the most demanding; use cobalt or carbide bits, lubricate liberally, and drill at slower speeds with frequent pauses to prevent work hardening. Always maintain steady pressure—pushing too hard can nick the bit or snap it.

Lubrication, speed, and feed: practical rules of thumb

Lubrication lowers friction and heat, extending bit life and improving hole quality. Start at a conservative speed and adjust based on chip color and sound; blue-hot or smoking bits indicate overheating and a need to slow down or pause for cooling. Feed rate should be steady but not aggressive; let the bit do the work. In production settings, a coolant system helps manage heat and prolongs the tool life across many holes.

Common mistakes to avoid

Avoid using wood or masonry bits for metal—their geometry won’t cut effectively and will dull quickly. Do not force the bit; excessive pressure increases heat and can cause breaking. Skipping lubrication leads to rapid wear; neglecting to clamp the workpiece causes wandering and inaccuracies. Finally, neglecting deburring leaves sharp edges that can cause injury or poor fit in assemblies.

Quick-start checklist for your first metal drill

Gather the right bits (HSS and cobalt at minimum), lubricants, clamps, a center punch, and PPE. Secure the workpiece, mark the hole, and start with a small pilot hole. Lubricate consistently, drill at a conservative pace, and clear chips often. Deburr the edges after drilling and verify hole size with a caliper or hole gauge.

Tools & Materials

- Metalworking drill bits (HSS)(Sizes matched to hole diameter; include 1/8", 1/4", 3/8" as common steps)

- Cobalt drill bits(Ideal for hard steels and stainless)

- Carbide-tipped drill bits(Best for repeated drilling into hard metals)

- Center punch(Create a precise starting point)

- Cutting oil or lubricant( Reduce heat and extend bit life)

- clamps or a vise(Secure the workpiece firmly)

- Drill (handheld or drill press)(Ensure it is rated for metal drilling)

- Eye protection and gloves(PPE to protect from chips and hot surfaces)

- Calipers or hole gauge(Verify final hole size)

- Chip brush or air blower(Keep chips clear during drilling)

Steps

Estimated time: 45-60 minutes

- 1

Set up and secure the workpiece

Position the metal on a stable surface and clamp it firmly to prevent movement during drilling. Verify accessibility for the drill bit to avoid kickback. A stable base reduces wandering and improves hole accuracy.

Tip: Always clamp on a solid surface; avoid suspending the workpiece. - 2

Choose the correct drill bit

Select a bit size that matches the planned hole diameter and choose material (HSS or cobalt) appropriate for the metal’s hardness. Check that the bit is sharp and clean before use.

Tip: If in doubt, start with a smaller pilot hole to guide the larger bit. - 3

Mark and center punch the hole

Mark the precise spot with a marker and center punch to create a small indentation. The indent helps the bit start reliably and reduces wandering on hard surfaces.

Tip: Use a light touch; avoid punching too deep or too hard. - 4

Apply lubrication and begin drilling

Apply a thin layer of cutting oil or lubricant to the marked area. Start drilling at a low speed with gentle pressure, allowing the bit to cut rather than burnish the surface.

Tip: Stop if the bit starts to grab; back off and re-align. - 5

Create a pilot hole first

Drill a shallow pilot hole slightly smaller than the final hole diameter. This guides the main bit and reduces heat buildup during the larger cut.

Tip: Peck the drill to clear chips and maintain lubrication. - 6

Drill the final hole and clear chips

Proceed to the final dimension with steady pressure and continuous lubrication. Periodically withdraw the bit to clear chips and prevent binding.

Tip: Avoid pushing hard; let the bit do the work. - 7

Deburr and inspect the hole

Remove burrs with a deburring tool and inspect hole dimensions for accuracy. Clean up any oil residue and ensure the surface remains smooth.

Tip: Deburring reduces injury risk and improves assembly fit.

Got Questions?

What drill bits go through metal?

For metal, use HSS bits for general work and switch to cobalt or carbide-tipped bits for hard metals like stainless steel. Wood bits or masonry bits will not perform well on metal and can dull quickly. Always verify the metal’s hardness and pick a bit accordingly.

Use HSS for soft metals and cobalt or carbide for harder metals like stainless steel. Avoid wood or masonry bits for metal.

Can I drill metal with a regular household drill?

Yes, a standard drill can drill metal provided you use metal-rated bits, proper lubrication, and operate at a slow, controlled speed. A drill press is recommended for precision and consistent pressure.

A regular drill can work if you use the right bits and control the speed; a drill press is better for precision.

Should I use lubricant when drilling metal?

Yes. Cutting oil or lubrication reduces heat, minimizes friction, and prolongs bit life. Apply sparingly along the cut line and reapply as needed during deeper holes.

Yes. Lubrication lowers heat and protects the bit; apply as you drill.

What speed should I drill stainless steel?

Drill stainless steel at a slow, controlled pace with ample lubrication. High speeds generate heat quickly and can dull or seize the bit.

Keep speeds slow and steady with plenty of oil when drilling stainless steel.

Is a center punch necessary?

A center punch is highly recommended. It creates a starting point that prevents wandering, especially on hard metals where precision matters.

Yes, it helps start the hole accurately and reduces wandering.

How do I remove a broken drill bit from metal?

If a bit breaks in the hole, stop drilling, back out carefully, and use proper extraction tools or tapping to loosen the fragment without enlarging the hole.

If a bit breaks, stop and use extraction tools to remove it without ruining the hole.

Can I deburr with hand tools after drilling?

Yes. Use a deburring tool or file to remove sharp edges. A smooth edge improves safety and helps with fitting parts.

Yes, use a deburring tool to smooth edges for safety and fit.

Watch Video

Top Takeaways

- Choose metal-specific bits (HSS, cobalt, carbide) for best results

- Center punches guide starting points and prevent wandering

- Lubrication reduces heat and extends bit life

- Secure the workpiece to avoid movement and misdrilling

- Deburr holes for fit and safety