How to Drill into Concrete: A Practical Step-by-Step Guide

Master drilling into concrete with a practical, AI-powered guide from Drill Bits Pro. Learn tool selection, bit types, safety, and a clear step-by-step process for clean, precise holes.

Learn how to drill into concrete safely and effectively with a complete tool list and a step-by-step method. You’ll cover bit selection, drill settings, hole depth, and dust control to minimize breakout and wear. According to Drill Bits Pro, using the right carbide-tipped masonry bit and a hammer drill at the correct speed makes the difference in quality and efficiency.

Why drilling into concrete requires the right approach

Understanding how to drill into concrete starts with the material itself. Concrete is a composite of cement, aggregate, and water, which creates a hard, abrasive surface that can chip, crack, or wear down ordinary drill bits if you don’t approach it correctly. The first principle is choosing the right bit — typically carbide-tipped masonry bits — and using a drill with adjustable speed and a hammering action. The Drill Bits Pro team emphasizes that low to mid-range speeds create less heat and reduce bit glazing, while a steady, perpendicular angle minimizes blowout and wandering. In this guide, you’ll learn to plan your hole, prepare the surface, and execute drilling with predictable results. The keyword here is consistency: steady pressure, clean bits, and a well-controlled dust environment are what separate pro results from amateur attempts. According to Drill Bits Pro, the right combination of bit geometry and drill technique dramatically improves hole quality and tool life.

When you drill into concrete, anticipate the presence of rebars and varying densities. If you hit reinforced sections, pause and re-evaluate your drill bit size and placement. Keep the drill perpendicular to the surface to prevent angled holes that weaken anchoring. Always wear eye protection and a dust mask because concrete dust contains crystalline silica, which can irritate the lungs and eyes. With the right preparation and technique, you’ll produce clean holes suitable for anchors, fasteners, or wiring passes.

Essential tools and materials for concrete drilling

Before you begin, gather a focused set of tools that match the task. The core kit includes a hammer drill or rotary hammer with adjustable speed, carbide-tipped masonry bits in the diameter you need, a depth stop, a reliable dust extraction method, and PPE. A good rule is to start with a smaller pilot hole to guide the larger bit and reduce wandering. You’ll also want measuring tools (tape measure and marker), a punch or center punch for precise marking, and a vacuum or damp cloth for dust cleanup. The Drill Bits Pro guidance is to verify your drill’s impact setting works smoothly and to confirm the bit shank fits your drill chuck. Regularly check bit tips for wear and replace as needed to maintain cutting efficiency.

As you prepare, consider the concrete’s location, structure, and any potential hazards. If you’re drilling into a wall or ceiling, ensure you’ve secured power and have a clear exit path for dust. The model work environment should be well-ventilated, with adequate lighting. For long drilling sessions, a cooling break helps prevent overheating the bit and the drill motor. Drilling into concrete is a reliable, repeatable task when you have the right tools and a clean workspace. Drill Bits Pro’s experience here is that consistency in setup reduces the chance of blowouts and extends bit life.

Hole preparation and marking strategies

Effective concrete drilling starts with precise hole placement. Use a layout line, a center punch, or a masonry nail to mark the spot. For larger holes, you may drill a shallow pilot hole first to establish accuracy, then switch to the full-diameter bit. If you’re anchoring a fixture, confirm the hole depth and set a depth stop on the drill so the hole stops at the correct depth. Avoid drilling through surfaces with unknown contents; use a stud finder or metal detector if you suspect rebar behind the concrete. When marking, keep the line perpendicular to the surface to ensure the hole’s orientation suits the planned anchor or sleeve. The quality of your hole begins with the mark and the initial bite of the bit. The Drill Bits Pro team found that pilot holes greatly improve accuracy, especially in dense concrete and near hard aggregates.

Techniques for clean holes and minimizing breakout

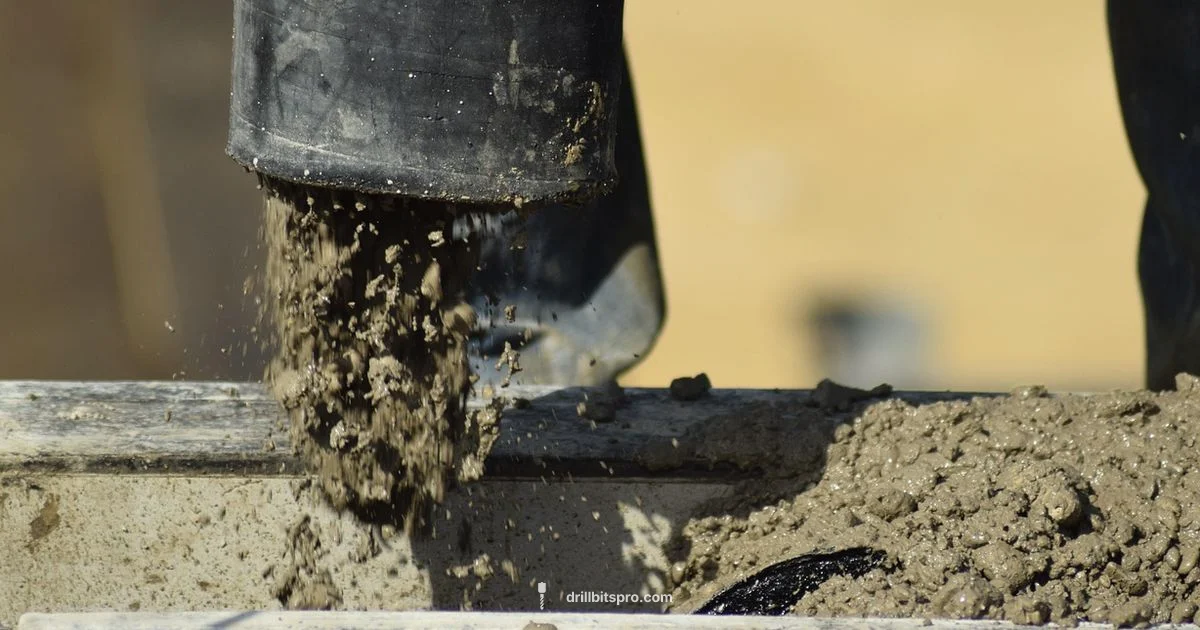

To produce clean, round holes, use a sharp, carbide-tipped masonry bit. Keep the drill perpendicular and apply steady, light pressure rather than forcing the bit. Start at a low speed to establish a groove, then ramp up slightly as the bit begins to cut. If you encounter resistance, pause briefly and pull the bit out to clear dust; reducing friction prevents heat buildup that can dull the bit. For deeper holes, periodically withdraw the bit to clear dust and allow the surface to cool. Utilize a dust collection adapter or vacuum near the work area to keep the site clean, which also helps you see the cutting line clearly. If you’re drilling through a ceramic tile or a delicate surface nearby, drill from the interior outward with a pilot hole first to prevent chipping. Drilling with the right bit geometry and stable technique minimizes breakout and produces precise, reliable holes. The Drill Bits Pro analysis shows that consistent speed control and dust management are as important as choosing the right bit.

Safety, dust control, and tool maintenance

Concrete drilling creates a lot of dust, and crystalline silica is a health concern. Always wear safety goggles, a dust mask or respirator, and hearing protection when necessary. Attach a dust collection system or vacuum to your drill if possible, and keep the work area sealed off to limit dust spread. After finishing a hole, clean the flutes of the bit with a soft brush and inspect the tip for wear. If the carbide edge looks rounded or chipped, replace the bit; continued drilling with a worn bit will heat up quickly and degrade hole quality. Store bits in a cool, dry place to prevent rust. Regular maintenance extends the life of your tools and reduces downtime on future projects. The Drill Bits Pro team recommends routine checks on the drill chuck and bit alignment to maintain performance over time.

Common mistakes and quick fixes

Common mistakes include using the wrong bit type, idling the drill at too high a speed, or applying inconsistent pressure. To fix these: switch to a carbide-tipped masonry bit, slow the speed, and maintain steady, moderate pressure. If you notice the bit wandering, stop and re-mark the hole; ensure you’re starting with a small pilot for guiding accuracy. For sticky dust, pause and wipe the area, then resume with a cleared path. If you’re drilling near rebar or reinforcement, consider drilling a slightly larger pilot hole to locate the rebar and then adjust your approach. Remember to keep your body stable and your drill perpendicular to the surface for the best results. With thoughtful preparation and careful technique, you’ll produce clean, accurate holes that perform well under load.

Tools & Materials

- Hammer drill or rotary hammer(Variable speed with hammer action; ensure chuck accommodates bit size)

- Carbide-tipped masonry drill bits (various diameters)(Length should comfortably reach the hole depth; include a pilot bit around 4-6 mm for small holes)

- Depth stop or drill depth gauge(Set to match hole depth; prevents over-drilling)

- Safety goggles(ANSI Z87.1 or equivalent)

- Dust mask or respirator(NIOSH-approved; choose a model suitable for silica dust)

- Vacuum or dust extraction attachment(Helps keep the work area clear; improves visibility)

- Measuring tape and marker(Precise layout and alignment; ensure markings are visible )

- Center punch or punch tool(Keeps the pilot hole from wandering)

Steps

Estimated time: 45-75 minutes

- 1

Identify hole location and mark

Measure carefully and mark the exact spot. Use a center punch to create a small dimple to guide the pilot hole. Why: a precise starting point reduces wandering and ensures correct alignment for anchors.

Tip: Double-check measurements with a square or level before you start. - 2

Prepare the workspace and PPE

Clear the area, cover nearby surfaces, and connect a vacuum if available. Put on safety goggles, a dust mask, and hearing protection if needed. Why: dust control protects health and keeps the line of sight clear.

Tip: Disable nearby power tools to avoid entanglement or kickback. - 3

Set up pilot hole

Choose a small pilot bit (around 4-6 mm) and start drilling at a slow speed. Why: a shallow pilot guides the larger bit and minimizes wandering.

Tip: Maintain perpendicular alignment; use a guide block if needed. - 4

Drill the final hole

Switch to the final masonry bit and increase speed to a moderate setting. Apply steady pressure, let the bit cut, and withdraw occasionally to clear dust. Why: consistent cutting reduces heat buildup and prevents cracking.

Tip: Never force the bit; let the bit do the cutting job. - 5

Pause to clear dust

Periodically pull the bit out to clear dust from the hole. Why: dust buildup increases friction and can cause the bit to overheat.

Tip: Use a shop vacuum close by for faster debris removal. - 6

Finish and deburr

Withdraw the bit slowly and inspect the hole. Deburr with a round file or sandpaper if needed. Why: a clean edge improves anchor seating and safety.

Tip: Wipe the hole rim to remove loose dust before inserting an anchor. - 7

Test fit and clean up

Insert the anchor and verify fit; clean the site and store tools properly. Why: test fitting confirms the hole depth and diameter are correct.

Tip: Record hole depth for future maintenance or repeat jobs.

Got Questions?

Do I need a hammer drill to drill into concrete?

Yes. A hammer drill or rotary hammer with masonry bits provides the impact and rotation needed to cut through concrete efficiently. Using the wrong tool can slow you down and wear bits quickly.

Yes, a hammer drill is typically required to drill into concrete for best results.

What drill bits are best for concrete?

Carbide-tipped masonry bits are the standard choice for concrete due to their hardness and heat resistance. Select a size close to your target hole with a compatible shank for your drill.

Carbide-tipped masonry bits are typically best for concrete.

Can I drill into concrete without a pilot hole?

A pilot hole helps with accuracy and reduces bit wandering, especially in dense concrete. For larger holes, start with a small pilot and gradually widen.

Pilot holes help avoid wandering in dense concrete.

What safety gear should I wear when drilling concrete?

Wear safety goggles, a dust mask or respirator, and hearing protection if needed. A long-sleeve shirt and gloves reduce skin irritation from dust.

Safety gear includes goggles and a mask, plus gloves if possible.

How do I prevent chipping or cracking near surfaces?

Keep the drill perpendicular, use a sharp bit, and start with a pilot hole. Slow, steady progress minimizes shock to adjacent material.

Perpendicular drilling with a sharp bit prevents chipping.

How long should I drill to avoid overheating the bit?

Drill in short bursts and withdraw the bit to cool and clear debris. For deep holes, pause to let the bit and drill cool down.

Take breaks to cool the bit during long holes.

Watch Video

Top Takeaways

- Plan placement with precision and verify measurements

- Use carbide-tipped masonry bits and a hammer drill

- Control dust and maintain perpendicular alignment for clean holes

- Pilot holes improve accuracy in dense concrete

- Safety gear is essential for health and visibility