How to Remove a Drill Bit from a DeWalt Drill: A Step-by-Step Guide

Learn a safe, step-by-step method to remove a stuck drill bit from a DeWalt drill. This guide covers tools, safety, and prevention tips to avoid future jams.

Quick answer: You can safely remove a stuck drill bit from a DeWalt drill by powering off, unplugging or removing the battery, securing the work, and using steady, controlled twists to release the bit. For those wondering how to get drill bit out of dewalt drill, this approach avoids hammering and damage. According to Drill Bits Pro, avoid hammering or forcing the chuck, and inspect for damage before reassembling. Follow these steps for best results.

Why the bit gets stuck in a DeWalt drill

Stuck drill bits in DeWalt tools are a common sight for DIYers and professionals. Debris in the chuck jaws, minor rust on the bit shaft, worn cutting edges, or misalignment can all cause binding. When a bit binds, yanking it free risks bending the bit, marring the chuck, or damaging the spindle. In this article on how to get drill bit out of dewalt drill, we focus on practical, field-tested steps you can perform with basic tools. This is not about brute force; it’s about controlled, repeatable motions that respect the tool’s tolerances. Drill Bits Pro analyses show that most stuck bits come from a combination of debris and tight holding—so starting with a clean jaw and a gentle extraction is often enough. Before any removal, inspect for obvious damage: chipped chuck jaws, excessive wobble, or a bent bit stem. If you notice significant wear, do not reuse the chuck until it’s serviced. A careful assessment now saves headaches later and keeps your DeWalt drill reliable for future jobs.

Safety and prep before you start

Safety is non-negotiable when dealing with jammed drill bits. Power down the tool, unplug the drill or remove the battery, and wear eye protection and gloves. Clear your workspace of clutter to prevent slips, and secure the drill so it cannot move during extraction. Keep a clean rag handy to wipe away dust and metal shavings. If you have a clamp or vise, use soft jaws to hold the drill without marring the finish. This phase reduces the risk of sudden slips that could injure fingers or damage the chuck. Drill Bits Pro’s guidance emphasizes a deliberate, orderly prep: the less you rush, the higher the probability you’ll remove the bit without collateral damage. After prep, you’ll have a safer base to proceed with the actual removal.

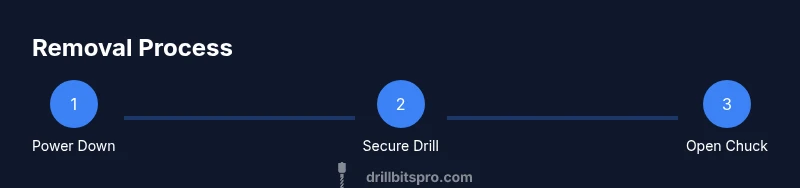

The standard removal sequence

With the drill secured and powered down, open the chuck jaws wide to expose the bit. If your DeWalt model uses a chuck key, insert the key and turn counterclockwise to loosen. If you don’t have a key, grip the bit with locking pliers only if you can do so without squeezing the shaft, then carefully twist the chuck counterclockwise to release. Apply a small amount of penetrating oil to the jaws if they feel stubborn or dry, and give it a moment to work. Then, reattempt the extraction with slow, steady motion rather than brute force. In most cases, a patient, evenly applied twist will free the bit without damage. If the bit remains stubborn, move to the chuck-removal method described in the next section. This approach minimizes stress on the drill’s spindle and extends the life of the chuck.

Handling stubborn cases: chuck removal and deeper access

Some stuck bits require removing the chuck from the drill to access the bit more directly. Start by stabilizing the spindle with a suitable tool and inserting a large hex key into the chuck. Tighten securely, then gently strike the hex key with a soft hammer to loosen the chuck’s grip on the spindle. Once loosened, unscrew the chuck from the spindle by turning counterclockwise in a controlled manner. If your DeWalt drill uses a left-hand retention screw inside the spindle, follow the manufacturer’s instruction to remove that screw first. After removing the chuck, reinsert the bit or swap in a new chuck if the existing one is compromised. Always verify there is no lingering heat or wear before reassembly. Drill Bits Pro notes that chuck removal is a last resort when the bit is deeply bound or the jaws are damaged; otherwise, stick to the standard method.

Aftercare and prevention: keeping the chuck healthy

Reassemble the drill and reinstall the chuck, ensuring all fasteners are clean and tight. Wipe the chuck’s interior with a clean rag to remove metal shavings that can accelerate binding. Use the correct bit size for each job to minimize excessive force, and avoid overtightening—the chuck should clamp firmly but not crush the bit shank. Regular maintenance includes lubricating the chuck mechanism with a light oil and testing the chuck by inserting several different bits to ensure smooth operation. Store your drill in a dry environment to prevent corrosion, and periodically inspect the chuck for wear. Following these steps will reduce future jam risks and extend the life of your DeWalt drill.

Tools & Materials

- DeWalt drill (with battery removed or unplugged)(Ensure power is off before starting.)

- Chuck key (if model requires one)(Keep handy during operation.)

- Allen wrench/hex key (for chuck removal if needed)(Use a size that fits the chuck’s hex socket.)

- Vise or clamp with soft jaws(Stabilizes the drill during extraction.)

- Penetrating oil or light machine oil(Optional if jaws feel dry or sticky.)

- Locking pliers (optional)(Can help grip the bit if a key is not available.)

- Safety glasses(Eye protection against metal shards.)

- Soft cloth/rag(Clean up debris and wipe oil.)

Steps

Estimated time: 20-40 minutes

- 1

Power down and secure the drill

Turn off the drill, remove the battery or unplug the cord, and set the tool on a stable surface. This prevents accidental start-up during extraction and protects your fingers from moving parts.

Tip: Never attempt removal with power connected. Keep the area clear and wear safety glasses. - 2

Secure the drill in a stable position

Clamp the drill in a vise or secure it with a sturdy workbench setup. Use soft jaws or a rag to prevent scratching the chuck while keeping the jaw area accessible for the next step.

Tip: A stable setup reduces the chance of slips that could injure you or damage the chuck. - 3

Open the chuck jaws and expose the bit

If your model uses a chuck key, insert it and turn to open the jaws wide. If there is no key, try to grip the bit with locking pliers only if you can do so without squeezing the shaft.

Tip: Be careful not to apply pressure on the bit’s cutting portion; focus pressure on the chuck jaws instead. - 4

Gently twist to release the bit

Apply a slow, counterclockwise twist to the chuck while maintaining a steady pull. If resistance remains, pause and reapply a light oil to lubricate the surfaces before trying again.

Tip: Patience is key—repeated small motions are safer than a single forceful yank. - 5

If stuck, consider chuck removal

If the bit won’t budge, remove the chuck from the spindle by inserting a hex key in the chuck, securing the spindle, and tapping the key lightly to loosen the chuck. Then unscrew the chuck from the spindle and extract the bit.

Tip: Use a wooden block to cushion impacts and avoid damaging the spindle. - 6

Reassemble and test

Reinsert the chuck and bit, tighten securely, and test with a light, unloaded drill to ensure smooth operation. If the chuck wobbles or feels gritty, service or replace the chuck before further use.

Tip: Always run a quick no-load test before resuming work.

Got Questions?

Can I remove a stuck drill bit without removing the chuck?

In many cases you can free a bit by opening the jaws and gently twisting, but if the bit is deeply bound or the jaws are damaged, removing the chuck may be the safer option.

You can often free a bit without removing the chuck, but if it won’t budge, removing the chuck is safer.

Why does a drill bit get stuck in a DeWalt drill?

Bits get stuck due to debris, corrosion, or excessive tightening. Misalignment or a worn chuck can also trap a bit, especially in older tools.

Bits get stuck because debris or wear makes the chuck grip too tightly.

Is it safe to strike the chuck with a hammer to loosen it?

Only use a hex key and light, controlled taps to loosen the chuck. Direct hammer blows on the chuck can damage bearings or misalign the spindle.

No heavy hammering; use the hex-key method and gentle taps instead.

What if the chuck is damaged after removal?

If the chuck shows wear or wobble after removal, replace it or have it serviced. A damaged chuck can compromise safety and drilling accuracy.

If the chuck is worn or damaged, replace it before continuing.

How can I prevent future drill bit jams?

Keep the chuck clean, use the correct bit size for the material, and lubricate the mechanism occasionally. Store tools in a dry environment to reduce corrosion.

Keep the chuck clean and use proper bits to prevent jams.

Do I need special tools for DeWalt models?

Most DeWalt drills use standard chuck removal tools (key, hex keys). Always refer to your model’s manual for model-specific steps.

Usually standard tools are enough; check your manual for specifics.

Watch Video

Top Takeaways

- Power down fully before any removal attempt

- Stability reduces risk of damage or injury

- Most jams free with slow, methodical twisting

- Chuck removal is a last resort and should be done carefully

- Regular chuck maintenance prevents future sticking