How to Remove a Drill Bit from a Drill: Safe Step-by-Step Guide

Learn a safe, step-by-step method to remove a drill bit from a drill. This practical guide covers prep, back-out techniques, and how to avoid chuck damage, with tips from Drill Bits Pro.

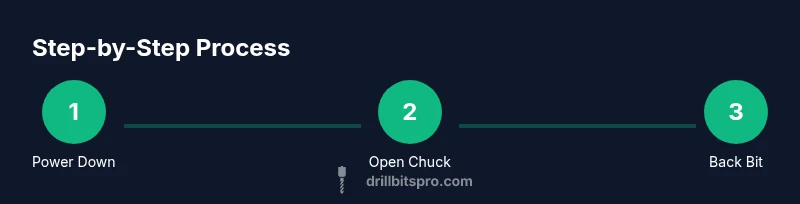

Safely remove a drill bit from a drill by following these steps. First, unplug the drill and open the chuck to release the bit. If it’s stubborn, insert an appropriately sized hex key into the chuck and back the bit out slowly, then grab with pliers to finish. According to Drill Bits Pro, proceed calmly to avoid damaging the chuck.

Understanding why drill bits get stuck

According to Drill Bits Pro, stuck drill bits are typically caused by debris or corrosion building up in the chuck, misalignment between the bit and chuck jaws, over-tightening, or forcing the bit when the jaws are not fully open. In some cases, heat from friction can weld the bit to the shank, especially with certain steel alloys. Identifying the root cause helps you choose the safest removal method and prevents repeat jams. Start by visually inspecting the bit, the chuck, and the shank for burrs, rust, or deformations. If you notice obvious damage beyond cleaning, plan to replace the chuck or bit rather than forcing removal, which could compromise tool safety.

Dirt, sap, or metal shavings can create adhesion that makes extraction tough, while mixed metals may seize due to oxidation. For any removal, keep the drill powered down, the bit controlled, and your hands clear of the jaws. Then consider the chuck type: keyed chucks require a chuck key to back the jaws, while keyless chucks rely on manual rotation. The approach you take will differ depending on the mechanism you’re dealing with, so take a moment to determine which path is appropriate.

Safety prerequisites and workspace setup

Before you touch the chuck, ensure the drill is completely powered down. Unplug the cord or remove the battery to eliminate any risk of accidental spinning. Secure the drill in a stable vise or clamp so it cannot move during removal, and align your workspace with good lighting. Wear impact-rated safety glasses, and consider gloves to protect your hands from sharp teeth of the chuck. Have a clean rag nearby to wipe away debris and a small brush or air can to clear dust from the chuck area. If you’re working with metal, consider a penetrating oil as a last resort—but apply sparingly and never near electrical contacts. A calm, methodical approach is essential; rushing increases the chance of damaging the drill or injuring yourself.

Chuck types and what removal methods work best

Most consumer drills use either a keyed chuck or a keyless chuck. A keyed chuck uses a separate tool (the chuck key) to tighten and loosen the jaws; turning the key counterclockwise usually loosens the grip. A keyless chuck relies on your hand to rotate the outer sleeve to open the jaws. When removing a stuck bit, the method depends on the chuck design: for a keyed chuck, you may back the bit out using the chuck key and a hex key; for a keyless chuck, you’ll typically back the bit out by rotating the chuck itself while securely holding the bit shank. In both cases, avoid twisting or forcing the bit if the jaws show resistance. If the drill is batteries or corded, ensure power is off before attempting to rotate the chuck and never pinch fingers in the jaws.

Step-by-step strategies for safe removal

Start with a simple back-out approach first. If the bit resists, switch to using the hex key as a lever, maintaining straight alignment. If the chuck is stubborn, non-destructive coaxial force with locking pliers can help. In rare cases where rust or corrosion locks the bit in place, applying a small amount of penetrating oil and giving it time to penetrate can loosen the bite. If the bit remains seized after all methods, do not continue to pry; consult a professional or replace the chuck.

Maintenance and prevention for the future

After removal, wipe the chuck clean and inspect for burrs; remove any seized debris; keep the chuck lubricated per manufacturer guidelines; replace worn jaws; store the drill with a reduced torque or unplug when not in use; Cleanliness and proper bit selection help prevent future jams. Regular maintenance reduces the chances of future sticking and prolongs the life of the chuck and bit. If you notice unusual play in the chuck or it won’t rotate smoothly by hand, stop using the tool and assess the broader condition of the drill.

AUTHORITY SOURCES

For further safety and best practices, consult these credible sources:

- https://www.osha.gov

- https://extension.psu.edu

- https://nap.edu

Tools & Materials

- Unplugged drill or removed battery(Power off before attempting removal to prevent injury)

- Chuck key (for keyed chucks)(Keep the key accessible; do not leave inside the chuck)

- Allen wrench / hex key(Size should fit the chuck and shank grips)

- Locking pliers (vise-grips)(Use to grip the bit shank securely without slipping)

- Rubber mallet(Helpful for light, controlled taps if the bit is only lightly stuck)

- Penetrating oil(Apply sparingly and only to the chuck area)

- Safety glasses(Protect eyes from chips and debris)

- Gloves(Provide grip and hand protection)

Steps

Estimated time: 20-40 minutes

- 1

Power down and secure the drill

Unplug the drill or remove the battery to prevent any rotation. Secure the drill in a vise or clamp so it cannot move during removal. Wear safety glasses and position the work area for clear access.

Tip: Double-check power is off before touching moving parts. - 2

Open the chuck to release the bit

If you have a keyed chuck, insert the chuck key and turn counterclockwise to loosen the jaws. For keyless chucks, grip the outer sleeve and rotate to open the jaws until the bit can move freely.

Tip: Support the bit end as the jaws loosen to prevent it from dropping. - 3

Assess the grip and plan the method

Check for debris, rust, or misalignment that’s causing the bind. Decide whether you will back the bit out with the hex key, or grip and pull with locking pliers, based on the chuck type.

Tip: If you feel real resistance, stop and reassess rather than forcing the bit. - 4

Back out with a hex key (if applicable)

Insert the hex key into the chuck area and rotate counterclockwise to back the bit away from the jaws. Use steady, even pressure and keep the tool aligned to avoid slipping.

Tip: Do not apply torquing force that could bend the hex key or shear the bit. - 5

Grip with locking pliers and extract

Once the bit has loosened enough, clamp the shank with locking pliers and pull straight out. Keep the pull gentle and controlled to avoid bending the bit or damaging the chuck.

Tip: Position the pliers as close to the shank as possible for maximum control. - 6

If still stuck, use oil and gentle taps

Apply a small amount of penetrating oil at the interface and let it sit for a minute. Gently tap the chuck or bit with a rubber mallet to loosen corrosion and debris, then try again.

Tip: Wipe away excess oil to prevent slippage in the next step. - 7

Inspect, reassemble, and test

Wipe the chuck clean, inspect for burrs or damage, and rotate the chuck by hand to confirm smooth movement. Reinstall any removed components and test with a scrap bit in a safe area.

Tip: Never power the drill while the chuck is not fully secured.

Got Questions?

What should I do first if the drill bit is stuck?

Power down the tool, unplug or remove the battery, and secure the drill before inspecting the bit and chuck for debris or damage.

First, unplug the drill and secure it, then check for debris or damage in the chuck.

Can I use oil to loosen a stuck drill bit?

A small amount of penetrating oil can help loosen corrosion. Apply sparingly, wait a moment, then retry the back-out method.

Yes, a little penetrating oil can help loosen a stuck bit; wait a moment and try again.

Is it safe to strike the chuck with a hammer?

No. Hitting the chuck can damage bearings or misalign the chuck. Use gentler methods first and avoid striking the tool.

No—don’t hammer the chuck. Try gentler back-out methods first.

What if the bit still won’t come out after trying?

Stop and reassess. Check for damage or corrosion, consider replacing the chuck, or consult a professional if needed.

If it won’t budge, stop, check for damage, and seek professional help if needed.

How can I prevent this from happening again?

Keep the chuck and bit clean, use correct bit sizes, avoid forcing, and perform regular maintenance.

Keep things clean, use the right size, don’t force it, and maintain your drill.

Watch Video

Top Takeaways

- Power down and secure the tool before any removal.

- Back out the bit using the appropriate chuck method without forcing.

- Grip with locking pliers and pull straight for stubborn bits.

- Inspect the chuck after removal and perform preventative maintenance.