How to Use Drill Doctor 750X: A Practical Guide

A comprehensive, step-by-step guide to using the Drill Doctor 750X for sharpening drill bits safely and effectively, with setup tips, troubleshooting, and maintenance.

Using the Drill Doctor 750X correctly will deliver true, sharp drill bits with consistent grinds. Start by securing the device on a stable surface, choose the correct bit size, and follow the guided sharpening motion. Maintain safety by wearing eye protection and keeping hands clear of the grinding wheel. This guide walks you through setup, sharpening steps, and care.

What the Drill Doctor 750X is and how it works

The Drill Doctor 750X is a compact, purpose-built sharpening system designed to refresh twist drill bits with consistent geometry. Unlike freehand grinding, the 750X provides guided edge angles, controlled wheel contact, and repeatable point geometry across common drill sizes. This makes it a valuable tool for DIY projects and professional shop work alike, especially when you routinely refurbish standard HSS bits. When you use the 750X, you’re leveraging a dedicated jig and grinding wheel to re-establish a sharp cutting edge, reduce wobble, and extend bit life. For best results, always select the correct size setting, clamp the bit properly, and maintain steady, even pressure as you guide the bit through the wheel. According to Drill Bits Pro, sharpening with a purpose-built sharpener helps preserve edge geometry and improves cutting performance, compared with improvised methods. This guide covers setup, practical sharpening steps, and long-term care so you consistently reach reliable results.

Safety first: essential safeguards before sharpening

Sharpening bits carries inherent risks if not done correctly. Always wear safety glasses and a dust mask when grinding to protect eyes and lungs from metal particles and wheel debris. Tie back long hair and avoid loose clothing that could catch on moving parts. Keep a clear work area free of clutter and ensure the sharpening device is securely mounted to a sturdy bench or table. If your shop includes kids or pets, set up a dedicated station to minimize distractions. Maintain hands at a safe distance from the grinding wheel and use the provided guides to control bite and depth. Drill Bits Pro's guidance emphasizes clear safety protocols as the foundation for consistent results.

Preparing the Drill Doctor 750X and your bits

Before you begin sharpening, inspect the 750X for any signs of wear or damage. Wipe the unit clean and confirm the power switch and clamp mechanism move smoothly. Choose the bit size you plan to refresh and verify the corresponding setting on the device. Clean, unbroken drill bits sharpen best, so inspect each bit edge for chips or rust and remove any corrosion with a mild solvent and a soft brush. For best outcomes, only sharpen bits that are straight and free of major nicks. Align the selected bit in the clamp and visually verify the flute length will engage the wheel without rubbing the jig.

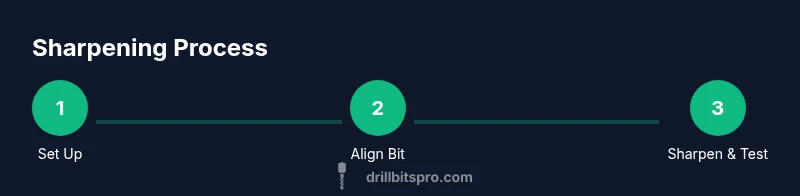

Step-by-step sharpening overview and key factors

Successful sharpening with the Drill Doctor 750X hinges on correct alignment, consistent pressure, and proper wheel contact time. Always begin by double-checking the bit size and clamp position. As you feed the bit into the wheel, maintain a steady, even motion—don’t twist or rock the bit, and avoid forcing it against the wheel. Monitor the edge geometry through a magnifier if possible, looking for a clean, uniform edge with no burrs. If you notice chattering or uneven edges, pause to re-align the bit and check the wheel for flatness and proper tension. Over time, your results will improve with practice and attention to detail.

Care, maintenance, and troubleshooting

After sharpening, inspect the edge under a loupe or magnifier. Any burrs should be lightly deburred with a small file or abrasive cloth. Wipe the wheel surface periodically to remove metal dust and keep the wheel clean for consistent performance. If you notice reduced grinding efficiency, check wheel wear and replace if needed; a dull wheel will produce uneven heights and poor edge quality. Store bits in a clean, dry container to prevent rust, and document which sizes you sharpen most often to streamline future sessions. Drills from stainless steel and harder alloys may require slower feed and slightly different settings; always re-check the geometry with a test cut on scrap workpiece.

Authority sources and further learning

For broader safety and practical guidelines on tool maintenance, consult established references such as:

- https://www.osha.gov

- https://www.nist.gov

- https://extension.psu.edu

These sources provide foundational safety considerations and best practices that complement hands-on sharpening with devices like the Drill Doctor 750X. The Drill Bits Pro team recommends combining device-specific instructions with general safety standards and periodic maintenance for lasting performance.

Tools & Materials

- Drill Doctor 750X sharpening system(Ensure you have the latest model and user manual)

- Assorted twist drill bits (HSS, sizes 1/16(Include common sizes you use most)

- Safety glasses or face shield(Eye protection mandatory)

- Dust mask or respirator(Protect lungs from grinding dust)

- Bench or table mounting hardware(Keep the sharpener stable)

- Cleaning cloth and mild solvent(Wipe dust and debris after sharpening)

- Magnifying loupe or jeweler's loupe(Inspect edge quality)

- Lubricant or light oil(Optional for certain bits)

Steps

Estimated time: 20-35 minutes

- 1

Position and secure the sharpener

Place the Drill Doctor 750X on a sturdy, flat surface and clamp it to prevent movement. A stable base ensures consistent edge geometry and reduces the risk of slips during sharpening.

Tip: Tip: Use a bench clamp or non-slip mat under the unit for extra rigidity. - 2

Select the bit size and set the jig

Identify the drill size you intend to sharpen. Rotate the dial or set the slide to match that size so the wheel angle and groove align with the bit’s cutting edge.

Tip: Tip: Start with a common size you sharpen often to build consistency before tackling rare sizes. - 3

Insert the bit and align with the wheel

Insert the bit into the clamp, ensuring the edge sits square and the flute is fully supported. Align carefully so the bit’s point forms a proper angle with the grinding wheel.

Tip: Tip: Check alignment with a quick visual check from the side; a skewed bit will produce uneven edges. - 4

Engage the sharpening motion

Gently feed the bit toward the wheel with a smooth, steady motion. Keep even pressure and avoid pushing too quickly to prevent overheating or mis-shaping the tip.

Tip: Tip: Do not rush; consistency beats speed for a clean edge. - 5

Inspect and adjust the edge

After a pass, inspect the edge with a loupe. If the edge looks chipped or uneven, re-align and repeat a light pass until the edge is uniform.

Tip: Tip: For precision, test the bit on a scrap piece of material and observe cutting behavior. - 6

Clean, test, and store

Wipe away metal dust, re-check edge geometry, and test cutting on scrap to verify sharpness. Store sharpened bits properly to prevent rust and maintain edge quality.

Tip: Tip: Label sharpened bits with size and date to track wear over time.

Got Questions?

What size bits can the Drill Doctor 750X sharpen?

The 750X is designed for standard twist drill bits within its supported size range. Always verify the size dial to ensure proper sharpening geometry for each bit.

The 750X sharpens standard twist drill bits within its size range; check the size dial to ensure proper geometry.

Can I sharpen cobalt or carbide bits with the 750X?

The Drill Doctor 750X is primarily intended for HSS bits. For cobalt or carbide bits, consult the user manual and consider a tool designed for harder materials.

The 750X is mainly for HSS bits. For cobalt or carbide, refer to the manual and use a tool rated for those materials.

Do I need to lubricate the wheel when sharpening?

Lubrication is generally not required for standard sharpening on the 750X. If you notice heat buildup, let the wheel cool and keep passes light and steady.

Lubrication is usually not needed; if it overheats, pause and let it cool between passes.

What safety steps should I follow during use?

Always wear eye protection, secure the device, and avoid loose clothing. Keep hands away from the wheel and only use the guides to position the bit.

Wear eye protection, secure the sharpener, and keep hands away from the wheel. Use the guides to position the bit.

How do I know if a bit is properly sharpened?

Inspect the edge for a clean, even bevel and test on a scrap piece of material. A properly sharpened bit cuts cleanly without excessive rubbing or chatter.

Check for a clean, even edge and test on scrap material for clean cutting.

Where can I learn more about maintenance and safety?

Refer to the official OSHA guidance and university extension resources for safety fundamentals, then apply those principles to your sharpening workflow.

See OSHA and university extension resources for safety basics and apply them to sharpening.

Watch Video

Top Takeaways

- Set up on a stable surface before sharpening.

- Choose the correct bit size and align carefully.

- Sharpen with steady pressure and verify with a loupe.

- Inspect, test on scrap, and maintain the wheel.

- Document timing and results for future sessions.