What Drill Size for M6 Tap: A Practical Guide

Learn the exact tapping drill size for M6 taps, plus material considerations, tolerances, and hands-on tips from Drill Bits Pro.

For an M6x1 coarse-thread tap, the standard tapping drill size is 5.0 mm. This hole size yields proper thread engagement in most metals when paired with appropriate lubrication and tapping speed. For M6x0.75 (fine pitch), use about 4.25 mm. Always test on a scrap piece to confirm the fit before final production.

What drill size for m6 tap

The M6 thread family is defined by a 6 mm major diameter, with common variants like M6x1 (coarse) and M6x0.75 (fine). When you prepare to tap, the drill size you choose directly influences thread depth, engagement, and strength. The simplest rule of thumb is to subtract the thread pitch from the major diameter to obtain the tapping drill size: D_tap = D_major − P. For an M6x1, that’s 6.0 − 1.0 = 5.0 mm. This 5.0 mm hole typically yields a robust internal thread in steel, aluminum, and other common metals when you maintain proper lubrication and controlled tapping speed. The Drill Bits Pro team emphasizes that using this standard size as a baseline reduces the risk of incomplete threads or stripped joints.

In practice, many DIY projects rely on M6x1 with a 5.0 mm tapping drill, while some applications needing a tighter fit may retune the drill size slightly after testing on scrap parts. If you’re working with a fine pitch, such as M6x0.75, the appropriate tapping drill size becomes 4.25 mm (6.0 − 0.75). In plastics, composites, or softer materials, you might experiment with a slightly smaller hole, but you should perform a scrap-test to confirm tolerance and thread quality before committing to production pieces. For hardened materials or tight-fit applications, consider a test hole, then validate with a go/no-go gauge and a sample tap.

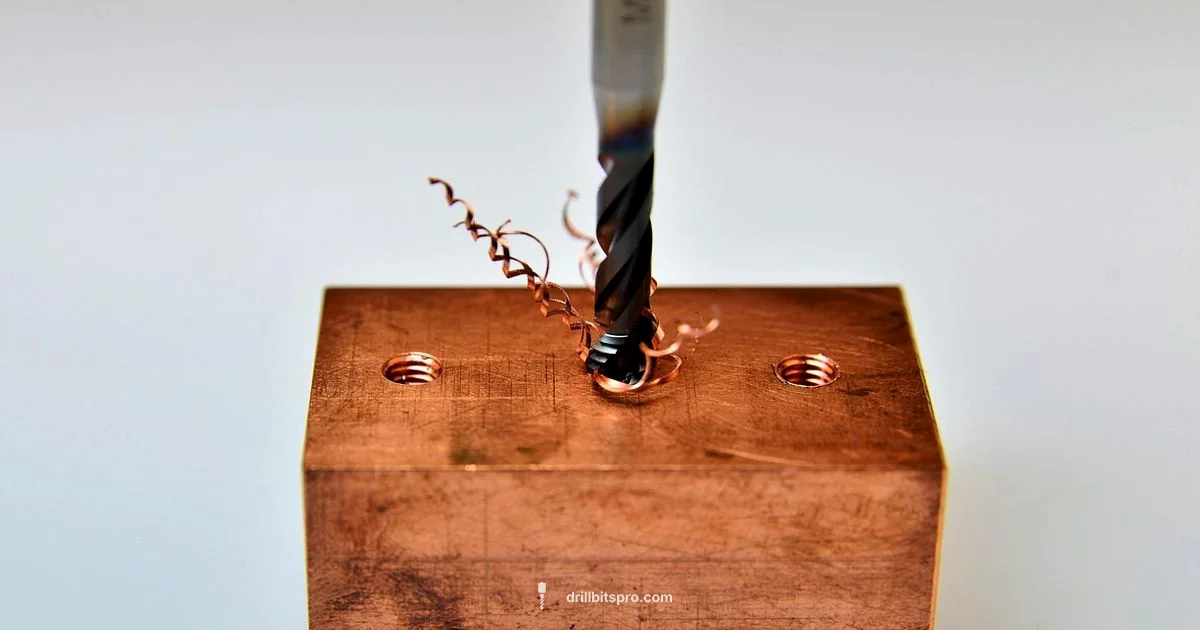

When selecting tools, ensure your drill bits are sharp, that you’re using the correct tap for the pitch, and that your workpiece is clamped securely to prevent movement during tapping. For consistent results, keep feed pressure steady and use a reliable cutting fluid or lubricant designed for metal tapping.

notes”:null,

Recommended tapping drill sizes for common metals (M6x1)

| Material | Recommended drill size (mm) | Typical pitch | Notes |

|---|---|---|---|

| Aluminum | 5.0 | 1.0 | Soft metal; easy tapping with lubrication |

| Carbon steel | 5.0 | 1.0 | Common choice; ensure lubricant and proper speed |

| Stainless steel | 5.0 | 1.0 | Harder material; use high-quality tapping fluid |

| Brass | 5.0 | 1.0 | Soft alloy; monitor for galling |

Got Questions?

What drill size should I use for M6x1 taps?

The standard tapping drill size is 5.0 mm. This serves as a reliable baseline for most metals. Test on scrap material if you’re unsure.

Use 5.0 mm for M6x1 taps, and test on scrap first.

Can I use a 5.5 mm drill for M6 taps?

A 5.5 mm drill will produce a looser thread. Only deviate if testing shows you need a larger core for your application.

5.5 mm can weaken the thread; test first.

What about M6x0.75 fine pitch?

For M6x0.75, use approximately 4.25 mm tapping drill.

Use 4.25 mm for M6x0.75.

Does material affect tapping size?

Yes. Harder materials may require careful tapping and lubrication; always test with scrap.

Material affects size; test first.

Should I use a drill press or hand drill?

A drill press improves accuracy for tapping; a steady hand with low rotation speed can work for softer metals.

Drill press is better for accuracy.

“Getting the drill size right is where thread engagement and strength begin. Start with the standard tapping drill for M6x1, then test and adjust if needed based on material and tool quality.”

Top Takeaways

- Always start with a 5.0 mm tap drill for M6x1.

- Test on scrap material before final production.

- Lubricate and deburr to ensure clean threads.

- Verify fit with a gauge before assembly.