Drill vs Impact Driver: A Practical Guide for DIY and Pros

A rigorous, practical comparison of drill and impact driver roles to help DIYers and pros choose the right tool for drilling holes and driving fasteners.

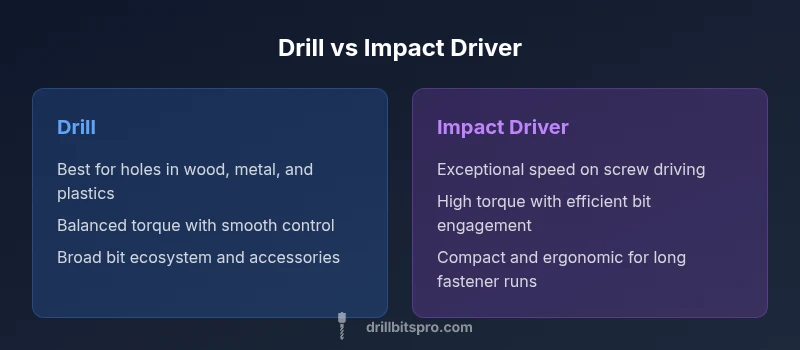

Both tools serve different jobs: a drill excels at making holes and handling light-to-medium drilling tasks, while an impact driver specializes in driving screws quickly with high torque. For most DIY projects, the drill-versus-impact driver decision hinges on whether you need versatile hole-making or fast, high-torque fastening. In practice, many professionals carry both to cover all bases.

The practical meaning of drill versus impact driver for your toolbox

Understanding the drill versus impact driver is essential for setting expectations about what each tool can do. At its core, the drill is a versatile hole-maker that handles a wide range of materials, from soft wood to dense metals, while the impact driver is engineered to maximize torque for fastener driving, especially when screws resist turning. The Drill Bits Pro team has observed real-world projects where the right pairing dramatically reduced time and effort. In practice, choosing between these tools—or deciding to own both—depends on your typical work: how often you drill holes, what materials you encounter, and how frequently you deal with fasteners. The goal is to match task demands with tool capability, not to insist on a single “best” option for every situation. This article uses practical tests and field-time observations to present a clear, task-oriented framework that DIY enthusiasts and pros can apply to their setups.

Core differences: torque, speed, and control

Torque and speed are the two axes that separate drill and impact driver performance, but control and feedback matter just as much. A drill delivers rotational force with smooth, adjustable speed, which makes it ideal for precision hole-making and pilot-hole work. An impact driver uses a hammering action coupled with rotation to deliver bursts of torque, reducing the effort needed to push a stubborn fastener. The result is faster screw driving with less wrist strain, especially on dense materials or long fasteners. Control comes from the clutch or variable-speed trigger on the drill and the torque-limiter or built-in clutch on many impact drivers. When used correctly, each tool reduces the risk of bit slipping, cam-out, or stripped screws. For users who routinely switch between drilling and driving, a hybrid mindset—recognizing the peak strengths of each tool—drives the most efficient outcomes.

When to choose a drill: drilling holes and mixed tasks

A drill shines when you need to create clean holes or perform light to medium drilling tasks across various materials. Woodworking projects, cabinet assembly, or pilot-hole creation for screws benefit from the drill’s broad bit ecosystem and comfortable control. Metal and plastic work also fall under the drill’s umbrella, especially when hole diameter choice and precision are critical. In many cases, pilot holes improve screw accuracy and reduce the chance of wood splitting. For tasks that require delicate bit tracking or step-by-step hole sizing, the drill’s steady RPM range and ability to accept a wide variety of bits are invaluable. If you foresee frequent drilling in different materials, a drill’s versatility becomes the deciding factor.

When to choose an impact driver: fastener tasks and heavy-duty driving

When the core job is driving screws, particularly long or heavy fasteners, an impact driver typically outperforms a drill. The hammering action reduces the torque you must apply with your wrist, enabling rapid fastening with less fatigue. This is particularly beneficial for deck construction, framing, and cabinetry where numerous fasteners must be seated flush or counter-sunk. An impact driver also excels with hex-shank bits and standard fastener protocols because its design emphasizes torque over precision drilling. For tasks that involve many screws or bolts, the impact driver becomes the efficiency engine of the toolkit.

Tool ergonomics, chuck types, and bit compatibility

Ergonomics often decide day-to-day comfort more than raw power. Drills typically feature larger, rounded grips optimized for extended drilling sessions, while impact drivers often emphasize compactness and a snug fit for one-handed operation. Chuck types on drills are commonly keyless and accommodate a wide range of bit sizes, whereas impact drivers use hex-shank bits with quick-release or secure-lock systems for rapid changes. Bit compatibility—bit length, shank type, and coating—matters for both tools. When choosing, consider the bit ecosystem you already own and the kinds of projects you foresee; the right bit selection and chuck compatibility streamline work and prolong tool life.

Real-world scenarios: project-by-project decisions

In a typical construction or woodworking project, you might drill pilot holes in a wooden frame with a drill, then switch to an impact driver for all deck screws and fasteners. For metalworking, you’ll want the drill for holes and a reliable carbide bit for material drilling, while keeping the impact driver on standby for quick assembly tasks. In furniture builds, predrilling with the drill and finishing with an impact driver can prevent strip-outs and speed up assembly. The nuance lies in matching bit types, screw sizes, and material hardness to the right tool. When uncertain, err on the side of using a drill for precision and the impact driver for torque-intensive work.

How to decide: a step-by-step framework

- List the typical tasks you perform (holes, driving, or both). 2) Estimate how often you’ll switch between drilling and driving. 3) Consider the materials you most frequently encounter. 4) Evaluate whether the torque needs are higher for fasteners or whether hole-depth control is paramount. 5) If budget permits, own both tools and designate roles (drill for drilling, impact driver for fasteners). 6) Check your battery platform compatibility to minimize waste and maximize interchangeability across tools. This framework keeps the decision grounded in real-world needs and avoids over-investing in a tool that will sit idle.

Maintenance, safety, and buying tips

Maintenance is often overlooked but crucial. Keep contacts clean, apply light oil to moving parts as recommended by manufacturers, and store bits properly to prevent damage. Safety includes eye protection, gloves, stable workpieces, and secure clamping when drilling or driving. When buying, prioritize a model with a comfortable grip, reliable ergonomics, and a modular battery system that suits your existing tools. Read user reviews for reliability and service quality, and consider a warranty that covers both the drill and impact driver. Finally, remember that a thoughtful combination of drills and impact drivers will typically deliver the best long-term value for any serious DIYer or professional.

Final tips and strategy: get the most out of your toolkit

To maximize productivity, treat the drill and impact driver as complementary rather than interchangeable. Build a small decision rubric for common tasks: drill for holes and light drilling, impact driver for fasteners. Keep a few essential bits and driver bits in a dedicated bit set, and ensure you maintain a clean, organized toolbox. With a balanced approach, you’ll experience smoother projects, fewer tool changes, and more reliable results.

Comparison

| Feature | Drill | Impact Driver |

|---|---|---|

| Best use | Hole-making and general drilling across materials | High-torque fastener driving and quick screw installation |

| Torque characteristics | Moderate torque with smooth control during drilling | Very high torque bursts optimized for fasteners; less precise drilling capability |

| Chuck/drive system | Varies by model; often keyless chucks for drill bits | Hex-shank bit drives with quick-change capabilities |

| Material handling | Excellent for wood, plastics, and softer metals with appropriate bits | excels with hardwoods and dense materials when driving long screws |

| Weight and ergonomics | Balanced for drilling tasks; comfortable grip for extended use | Compact and ergonomic grip geared toward fastener work |

| Bit ecosystem and accessories | Broad range of drill bits, brad point bits, twist bits, spade bits | Wide selection of hex bits, driver bits, and specialty driving bits |

| Cost/value context | Affordable option for basic applications; versatile for entry-level users | Higher value when heavy fastener work dominates projects; efficient for large screw counts |

What's Good

- Versatile tool pair covers drilling and fastening needs

- Impact driver speeds up screw-dominant tasks

- Drill provides precise hole-making and material control

- Extensive accessory ecosystems support a wide range of projects

Negatives

- One tool may not suffice for all tasks; may require both

- Impact drivers can damage bits if misused with non-fastener tasks

- Drills can be less efficient for repeated heavy driving without high-torque variants

For most projects, pair both: use a drill for holes and light driving, and an impact driver for fastener work.

Choosing between drill versus impact driver depends on the task. A drill is your go-to for hole-making and versatility, while an impact driver excels at heavy-duty fastening. If you frequently alternate between drilling and driving, owning both tools provides the best overall efficiency and results.

Got Questions?

Can I substitute an impact driver for a drill when drilling holes?

An impact driver is not ideal for precision drilling and can be harsher on bits and materials. Use a drill for creating clean holes and pilot holes.

An impact driver isn’t the best tool for drilling holes; use a drill for precise hole work.

Is an impact driver stronger than a drill?

In driving power, yes—impact drivers deliver higher torque bursts. For drilling, power depends on the model, with drills offering steadier, controlled performance.

Impact drivers are stronger for driving; drills are better for drilling.

Do I need a hammer drill for masonry?

For masonry tasks, a dedicated hammer drill or rotary hammer is typically necessary. A standard drill or a typical impact driver isn't ideal for brick or concrete.

A hammer drill is usually required for masonry work.

Can I use the same battery for both tools?

Most cordless drills and impact drivers are built on compatible platforms, so you can often swap batteries across tools within the same brand.

Yes, many brands share batteries across tools, simplifying setups.

What safety precautions should I take?

Wear eye protection and gloves, secure the workpiece, and use clamps. Follow manufacturer safety guidelines and avoid forcing bits or fasteners.

Always wear PPE and fix work securely before drilling or driving.

What about price and value?

Prices vary by features, but investing in a capable drill and an efficient impact driver often saves time. Compare total cost over the life of the tools rather than just the upfront price.

Look at long-term value—not just the sticker price.

Top Takeaways

- Prioritize a drill for hole-making and versatility

- Choose an impact driver for high-torque fastening

- Consider ergonomic weight when choosing between tools

- Many pros keep both for maximum efficiency