How to Fix Drill: Step-by-Step Repair Guide

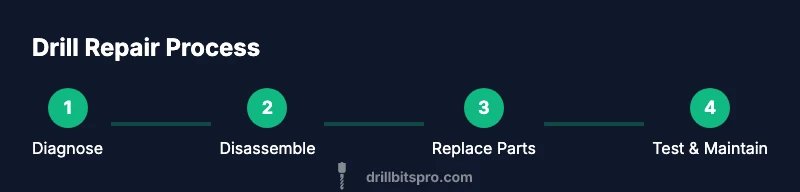

Learn how to fix drill safely with a practical, step-by-step guide. Diagnose common issues, decide repair vs replacement, disassemble, replace parts, and test for reliable performance.

Learn how to fix drill with a practical, safe approach. This guide covers diagnosing common symptoms, choosing between repair and replacement, and step-by-step disassembly, part replacement, and testing. By following these steps, you’ll extend your drill’s life and avoid costly downtime. Always prioritize safety and use proper tools. It also highlights when professional service is warranted and how to document the repair for future maintenance.

Why Fixing Your Drill Saves Time and Money

According to Drill Bits Pro, learning how to fix drill problems empowers DIY enthusiasts and professionals to extend tool life and reduce downtime. When you know the common failure modes and the right repair approach, you avoid costly replacements. In this guide on how to fix drill, you’ll explore practical diagnostics, safe disassembly, and parts replacement strategies that apply to most household and workshop drills. You'll also see how regular maintenance and careful operation cut the total cost of ownership. By focusing on repair rather than disposal, you gain a reliable skill that pays off over years of projects. This section lays the foundation: repair is often faster than waiting for service, and many failures are the result of wear, overheating, or simple misalignment that you can fix with common tools and a patient approach. The goal is not just to fix a single drill but to build a repeatable workflow you can repeat on future tools.

Common Symptoms That Indicate a Drill Needs Repair

Drills fail in predictable ways that point to specific parts. If your drill won’t spin or only hums when you pull the trigger, the issue could be a worn carbon brush, a stuck switch, or a power delivery problem. If the drill runs intermittently, check for loose wiring, a failing trigger, or a degraded battery connection. Smell of burning or a growling/whining gear noise often signals bearing wear or seized gears. Drilling slowly, or heating quickly without load, can indicate motor or clutch problems. In this block we outline quick checks you can perform safely, and we discuss how to distinguish battery issues from inside-the-tool faults. Based on Drill Bits Pro analysis, many early-stage faults are battery-related or due to worn brushes, which are among the easiest repairs to address with common parts. Understanding symptoms helps you decide whether you can fix it yourself or should seek help.

Safety First: Prep and Shutdown Procedures

Safety is non-negotiable when repairing a drill. Always unplug the drill or remove the battery before touching moving parts to prevent accidental starts. Work in a well-lit, ventilated area with clear space to spread out screws and small parts. Wear eye protection and gloves as needed, and keep a trash-free workspace to avoid losing tiny components. If you’re dealing with a corded tool, unplug from the wall outlet and tape the switch to the off position when needed during disassembly. A grounded, static-free surface helps prevent damage to electronics inside the tool. By establishing safe habits at the start, you reduce the risk of shock, cuts, or accidental injuries and ensure a cleaner diagnostic process.

Tools and Parts You Might Need

Before you start, assemble a basic repair kit tailored to your drill. Essential items include a screwdriver set with Phillips and flathead bits, needle-nose pliers, a multimeter for electrical checks, and a clean magnetic tray to keep tiny screws organized. Depending on your model, you may need replacement carbon brushes, a new switch, or a bearing kit. Lubricants such as light machine oil or white lithium grease are helpful for reassembly. Have spare parts on hand only after you have correctly diagnosed the worn components so you don’t stock unnecessary items. Finally, a camera or smartphone to document disassembly steps can be very valuable for reassembly.

Diagnostic Checklist: How to Identify the Root Cause

A systematic diagnostic routine saves time and avoids unnecessary part swaps. Start by inspecting the battery and charging system for cordless tools; check voltage with a multimeter and look for corrosion on contacts. If the battery is healthy, move to the switch and trigger—their internal contacts can wear and cause intermittent operation. Remove the back cover to inspect wiring and connectors, looking for loose or pinched wires. Check the commutator and brushes if present; worn carbon brushes are a common cause of low performance. For mechanical issues, listen for grinding, grinding, or binding sounds that may indicate bearing wear or gear misalignment. When in doubt, test continuity with a multimeter or a simple resistance check to confirm a fault.

Disassembly Best Practices for Safety and Longevity

Disassembly should be deliberate and organized to protect fragile components. Start by unplugging or removing the battery, then photograph or sketch each step to guide reassembly. Keep screws grouped by location and use a magnetic mat. As you open the housing, handle springs and small parts with care to avoid losing them. If you need to pry, use non-metallic tools to minimize marring. When you reach the motor assembly, avoid touching the windings and use insulated tools to prevent shorts. Clean debris from the housing and check for misaligned gears before proceeding with any replacement.

Replacing Components: Bearings, Switches, and Brushes

If inspection shows wear, replacement is the most reliable fix. Replace carbon brushes only if the length shows significant wear or the contact surface is uneven. Install a new switch if the trigger doesn’t return smoothly or has a delayed response. Bearings are often accessible behind the end cap; replace them if you feel roughness or hear grinding during rotation. After installing components, lightly lubricate moving parts and reassemble. Recheck the fit and clearance before testing. Keep notes of the parts you replaced and be sure you are using the correct type and size for your model. When unsure, consult the manual or manufacturer’s part numbers.

Reassembly and Functional Testing

Reassembly should mirror the reverse order of disassembly. Start by reattaching any insulation or shielding, then snap the housing back together while ensuring all wires are correctly seated. Reinsert screws in their exact positions, avoiding overtightening that could strip threads. Reconnect the battery or plug in the cord and perform a controlled test run without a drill bit installed. Test the trigger, variable speed, and chuck engagement under light load first, then with a bit to verify performance. Listen for unusual noises, watch for overheating, and watch the operation of the gears. If anything seems off, pause and re-check connections and parts alignment before applying full torque.

Maintenance and When to Replace: Final Checks and Preventive Tips

Even repaired drills benefit from preventive maintenance. Clean the exterior and vent openings after use to prevent dust buildup in the motor. Lubricate moving parts sparingly to reduce wear and avoid attracting dust. Use correct drill bits and apply the right speed and pressure for each material. Store tools in a dry, organized space to prevent corrosion or damage to the electrical contacts. Establish a routine: inspect the brushes and switch every few months and replace components before they fail. The Drill Bits Pro team's guidance emphasizes treating repairs as a learning process and developing habits that extend tool life and performance. By following these practices, you’ll keep drills performing reliably for new projects.

Tools & Materials

- Corded or cordless drill(Identify model and battery type before repairs)

- Screwdriver set (Phillips and flathead)(Sizes #1-3, vary by model)

- Needle-nose pliers(For gripping small parts and wires)

- Multimeter or continuity tester(Useful for electrical checks)

- Replacement carbon brushes or switches(Only if you confirm wear or failure)

- Lubricant oil or white lithium grease(For gears during reassembly)

- Safety glasses and gloves(Personal protective equipment)

- Magnetic parts tray(Keeps tiny screws organized)

- Camera or phone for documentation(Helpful for reassembly)

Steps

Estimated time: 60-120 minutes

- 1

Disconnect power

unplug or remove the battery to prevent accidental starts during any handling of moving parts. Safety first.

Tip: Always confirm the tool is de-energized before touching internal components. - 2

Remove the chuck to access internals

Gently loosen and remove the chuck so you can inspect gears, bearings, and the spindle without obstruction.

Tip: Support the spindle to avoid damaging bearings or threads. - 3

Inspect carbon brushes

Check brush length and contact surfaces; worn brushes reduce performance and can cause arcing.

Tip: Replace if brushes are worn beyond the manufacturer’s guidance. - 4

Check electrical connections

Inspect wires and connectors for corrosion, loose crimps, or pinched insulation that could cause intermittent operation.

Tip: Document any damaged connectors for replacement. - 5

Test motor windings

Use a multimeter to check continuity and resistance as a basic motor health check.

Tip: Follow safe testing procedures; disconnect power before testing. - 6

Inspect gears and bearings

Look for wear, pitting, or binding that could cause grinding or poor runout.

Tip: Turn gears by hand to feel for rough spots or looseness. - 7

Replace worn parts

Install new brushes, a switch, or bearings as needed after confirming wear through inspection.

Tip: Match part numbers to your model and test fit before final assembly. - 8

Lubricate and reassemble

Apply a thin layer of lubricant to moving parts and reassemble housing in the reverse order of disassembly.

Tip: Wipe away excess lubricant to prevent dust attraction. - 9

Test operation

Run a controlled test with no load, then with a bit installed to confirm proper operation and safety.

Tip: Listen for abnormal sounds and monitor for overheating during the test.

Got Questions?

What is the first step to fix a drill safely?

Always unplug or remove the battery before handling any internal components. This prevents accidental starts and reduces shock risk.

Always unplug the drill or remove the battery before you begin.

Can all drill problems be repaired at home?

Many common issues like worn brushes, faulty switches, or loose connections can be repaired at home with basic tools. More complex motor problems may require professional service.

Some problems you can fix at home, but bigger motor issues may need professional help.

How do I know if carbon brushes need replacement?

Inspect brush length and contact area; replace when brushes are worn past the manufacturer’s minimum length or when the contact surface is uneven.

Check the brushes and replace if they’re visibly worn or uneven.

Is it safe to continue using a drill after partial disassembly?

If the drill runs roughly, stops, or smells burning, stop and re-check components. Do not continue using a damaged tool.

If it runs poorly or smells, stop and re-check before using it again.

Should I lubricate gears during reassembly?

Yes, apply a light layer of suitable lubricant on gears and moving parts, but avoid over-lubricating as dust will stick to excess grease.

Light lubrication helps; don’t overdo it.

How can I prevent future drill failures?

Regular cleaning, correct bit usage, proper speed and pressure, and storing the drill in a dry place reduce failures and extend life.

Keep it clean, use the right bits, and store it properly.

Watch Video

Top Takeaways

- Diagnose before disassembly to save time

- Always prioritize safety and proper tools

- Use model-specific parts to ensure compatibility

- Test thoroughly after repair to confirm success

- Regular maintenance extends drill life and reliability