How to Make a Hole Without a Drill: Step-by-Step Guide

Learn practical, safe methods for making holes without a drill. This expert guide covers wood, metal, and masonry with step-by-step approaches and safety tips.

Learn how to make a hole without a drill using safe, proven methods. This guide covers wood, metal, and masonry, with hands-on steps like using nails, awls, punches, or heat. According to Drill Bits Pro, choose the method based on material, hole size, and safety. Whether indoors or outdoors, you’ll plan, select tools, and execute with control to reduce damage and injury.

What it means to make a hole without a drill

In many DIY projects, you’ll reach a moment where a hole is needed but a drill isn’t available or practical. The phrase how to make a hole without a drill is a common search for woodworkers, metalworkers, and builders alike. This article walks through several reliable approaches that rely on hand tools, heat, pressure, or abrasive methods. You’ll learn to assess the material, select the proper method, and apply it with control to avoid cracks, burrs, or misalignment. According to Drill Bits Pro, the best results come from matching the method to the material and the hole’s diameter, rather than forcing a one-size-fits-all technique. With careful planning, you can often achieve a clean starting point and an accurate bore without power tooling. The goal is not to replace a drill but to provide safe, repeatable options when a drill is unavailable or impractical. In this guide, you’ll find practical steps, material-specific tips, and safety reminders to protect your eyes, hands, and work surface. If you want a quick overview, you’ll also find a concise quickAnswer above, but the detailed steps below offer the nuance that DIYers and professionals expect. The Drill Bits Pro team found that practicing on scrap material first reduces the risk of error.

Safety first: assess materials and hazards

Before attempting any non-drill hole, evaluate the material type, thickness, and surrounding structure. Wear safety glasses or a face shield, gloves, and hearing protection when using metal, heat, or impact methods. Keep your work area clear of clutter and ensure good lighting. For wood, metal, and masonry, different starting points and protective steps reduce the chance of cracking or shattering. As you read, remember that accuracy matters more than speed, and a measured approach lowers the risk of injury. Drill Bits Pro analyses show that a cautious, material-specific plan yields more reliable holes than brute force alone. If you’re inexperienced, practice on scrap pieces first and test fits before committing to the final piece. Safety is not optional here; it’s your first tool.

Woodworking techniques: creating holes in wood

Wood is forgiving compared with metal or masonry, but it still benefits from careful preparation. Start with a sharp center punch or a sharp nail to create a faint starting point. Use an awl or a brad-point nail to create a small pilot hole, then widen gradually with a suitable hand-cutting tool such as a hammer drill substitute (e.g., a sharpened screwdriver or a thin chisel) while applying steady pressure. For larger holes, use a hand auger or a drill-free bit driver, but only after you’ve established a solid pilot. Always work with scraps to verify alignment and avoid tear-out on the top surface. The key is to work slowly, check depth frequently, and deburr the edge with a file or sandpaper for a smooth finish.

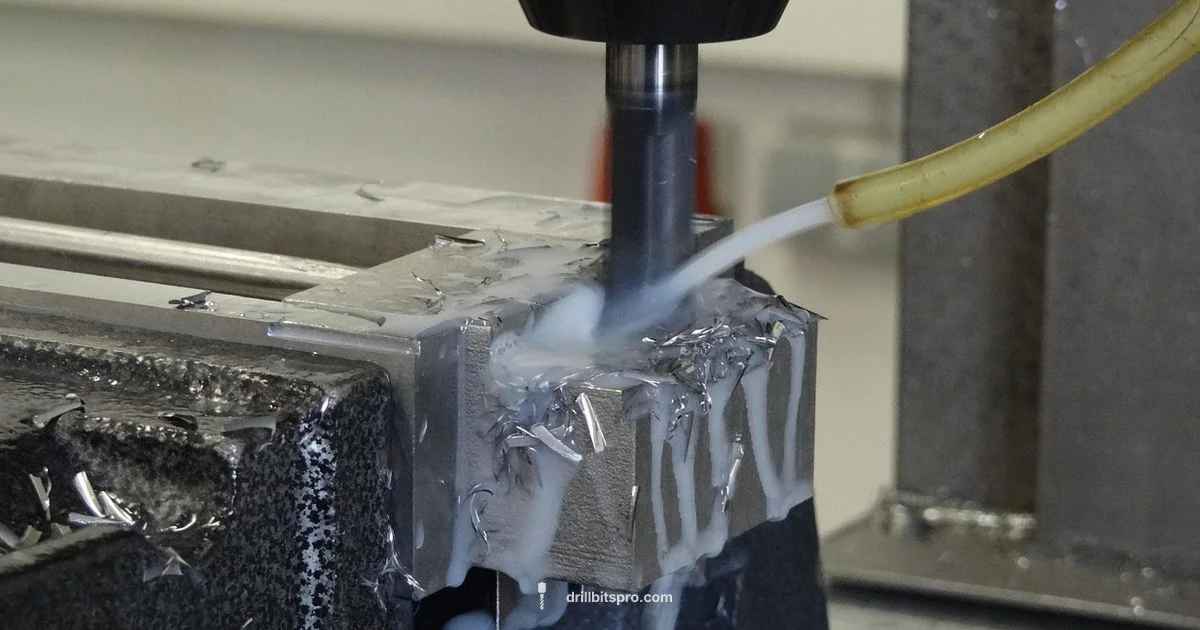

Metalworking techniques: punching and reaming

Metal requires different tactics. Start with a center punch to locate the hole center, then use a hardened nail or punch and a hammer to drive a starting point. For soft metals like aluminum, a sharp punch can create a clean starter; for steel, you’ll need progressively larger punches or a handheld punch set and a corresponding drill-free reamer to enlarge the hole. Protect the surface with a sacrificial block and wear eye protection for metal chips. If you’re working with torsion or a high-load area, consider testing the approach on scrap metal first and monitor for drag or binding that could injure your hand. Drilling without a drill in metal is about controlled aggression rather than brute force, and the right tool makes all the difference.

Masonry and concrete: alternative approaches

Masonry and concrete are the toughest to bore without a drill. The most reliable non-drill approaches involve using a carbide-tipped nail or masonry punch on a pre-marked center point and gradually widening by tapping with a hammer, or employing a cold chisel and hammer to create a starting notch for a larger cavity. This technique is slow and requires patience; heat should be avoided on most masonry materials to prevent cracking. For very hard concrete, you may need to rent or borrow a hammer drill as a practical option. Always wear eye protection and protect nearby surfaces from dust and chips. Drill Bits Pro notes that for structural work, professional tools and methods are recommended to maintain safety margins and durability.

Tools and improvised substitutes: what to use and what to avoid

A surprising amount of success comes from combining common tools creatively. An awl, center punch, nail set, and small hammer enable starting points and controlled openings in wood and metal. For smaller holes, a heated nail or wire can soften the material’s resistance just enough to begin a groove. Avoid using blunt force on finished surfaces or delicate components, as this can crack or deform the material. Keep a set of scrap pieces handy for practice, and document which methods yield the best results for different materials. As always, safety gear is non-negotiable; eye protection is essential when chips or splinters are possible. The right approach depends on material, hole size, and the work environment.

Finishing the hole and cleanup: getting a clean edge

Once the hole is started, finish with deburring tools or light sanding to remove burrs. If the hole edges are rough, wrap sandpaper around a small dowel or a rod and twist gently to smooth the circumference. Clean the area with a soft brush to remove dust and debris. Check the hole for size against the intended fastener or insert, and adjust as needed using a reamer or fine hand file. A crisp edge improves fit and reduces wear on fittings. Document any notable challenges for future projects to improve your technique over time. Remember that practice with scrap material builds confidence and accuracy.

When to switch to powered tools or call a pro

If the hole must be precise, wide, or deep, and your non-drill method isn’t achieving the required result within a reasonable timeframe, it’s prudent to switch to powered tools or consult a professional. In many scenarios, a small hand drill or cordless screwdriver can be rented or borrowed at short notice, offering a safe, controlled alternative without committing you to an improvised method. The decision to escalate should consider material integrity, hole tolerance, and project deadlines. The Drill Bits Pro team recommends evaluating cost, safety, and finish quality before widening a hole beyond your capability with hand tools.

Tools & Materials

- Hammer(Claw hammer or ball-peen hammer depending on material)

- Center punch or sharp nail(For precise starting point)

- Awl or brad-point nail(Creates small pilot hole)

- Nail set(For finishing flush countersinks)

- Sharp chisel(Widen starting point in wood/metal)

- Scratch awl or hardened punch(Additional starting accuracy)

- Pliers or needle-nose pliers(For chip removal and grip)

- Safety gear (glasses, gloves)(Eye protection is essential)

- Scrap material for practice(Test the method before final work)

- Rasps or fine file(Finish and deburr edges)

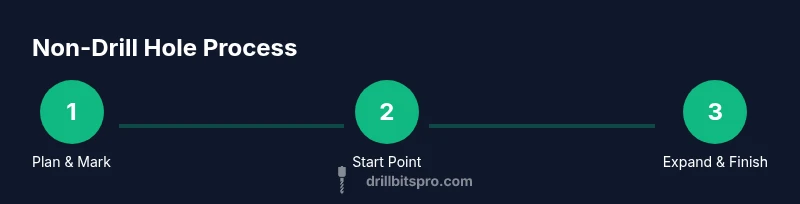

Steps

Estimated time: 60-90 minutes

- 1

Assess material and plan hole

Identify the material and the required hole diameter. Decide on the method based on material type and thickness. Gather all tools and mark the final position on scrap first if possible.

Tip: Choose a method with the least risk of cracking or shattering. - 2

Mark the location clearly

Use a center punch or a sharp nail to create a small dimple at the center. This guides the starting tool and helps prevent wandering.

Tip: Double-check alignment before striking. - 3

Create a starting point

Drive a small pilot point using an awl or punch. Keep the force controlled to avoid widening the mark beyond the target diameter.

Tip: If the material resists, pause and test on scrap. - 4

Widen the hole gradually

Carefully expand the opening with the chosen method (punching, chiseling, or partial reaming). Progress in small increments and check fit frequently.

Tip: Do not force the tool; if it binds, stop and reassess. - 5

Finish the edge and deburr

Remove burrs with a file or sandpaper wrapped around a dowel. Clean the surface to prepare for fitting or finishing.

Tip: Deburring reduces catching and improves fit. - 6

Test and adjust

Insert the intended fastener or tool to verify fit. If too tight, remove a small amount and re-check.

Tip: Always test in the actual hole with the final component. - 7

Clean up and store tools

Wipe down tools, put heated tools aside safely, and return them to their sheath or case. Document what worked for future projects.

Tip: Keep a small notes pad handy for quick references. - 8

Reflect on safety and environmental impact

Dispose of metal chips and dust properly. Reassess PPE and workspace layout to prevent accidents on future projects.

Tip: A tidy workspace prevents injuries later.

Got Questions?

Can you drill through masonry without a drill?

Drilling through masonry without a drill is possible with careful tapping and chiseling, but it is slow and risky. For professional results, a hammer drill or rotary tool is typically needed. Always assess safety and structural considerations before attempting any masonry work.

Drilling masonry without a drill is possible but slow and risky; consider safer, professional options for best results.

Is heating metal a safe technique for starting a hole?

Heating metal to soften it can work for soft metals but can introduce warping or unwanted changes in temper. Use small, controlled heating and wear heat-resistant gloves. Avoid heating alloys that may emit toxic fumes.

Heating metal can help start a hole in soft metals, but use caution and protective gear.

What PPE should I wear when making a hole without a drill?

Wear safety glasses or a face shield, gloves, and hearing protection if using impact tools. A dust mask may be appropriate for wood or dusty materials. Ensure the work area is well-ventilated and free of trip hazards.

Always wear eye protection and gloves; ensure good ventilation and a clear workspace.

When should I avoid non-drill methods and switch to powered tools?

If the hole requires high precision, a large diameter, or deep depth, switch to a powered tool or consult a professional. Non-drill methods can be slower and less accurate for challenging tasks.

If precision or depth becomes critical, switch to powered tools.

Can I use everyday household items to start a hole in wood?

Yes, items like an awl, sharp nail, or small punch can start a hole in wood. Use scrap wood to practice and verify alignment before working on your final piece.

Household tools can help start a hole in wood, but practice first with scrap.

Is there a risk of damaging the surface when starting a hole?

There is always some risk of scratches or tear-out if starting points are not precise. Use a center punch and light, controlled strikes to minimize damage and check depth as you go.

Yes, start precise and go slow to avoid surface damage.

Watch Video

Top Takeaways

- Plan the hole size and starting point before any action.

- Match the method to material to avoid damage.

- Mark precisely and center punch for accuracy.

- Progress gradually and test frequently for best results.

- Prioritize safety and proper cleanup after work.