What Drills Are Used For A Practical Guide

Discover what drills are used for, how to choose the right drill, essential drill bits, safety practices, and maintenance tips to keep your tools performing at their best.

A drill is a power tool that creates holes or drives fasteners by rotating a drill bit. It is a type of hand-held or stationary tool, available in corded, cordless, and specialized variants for wood, metal, or masonry.

What drills are and what they are used for

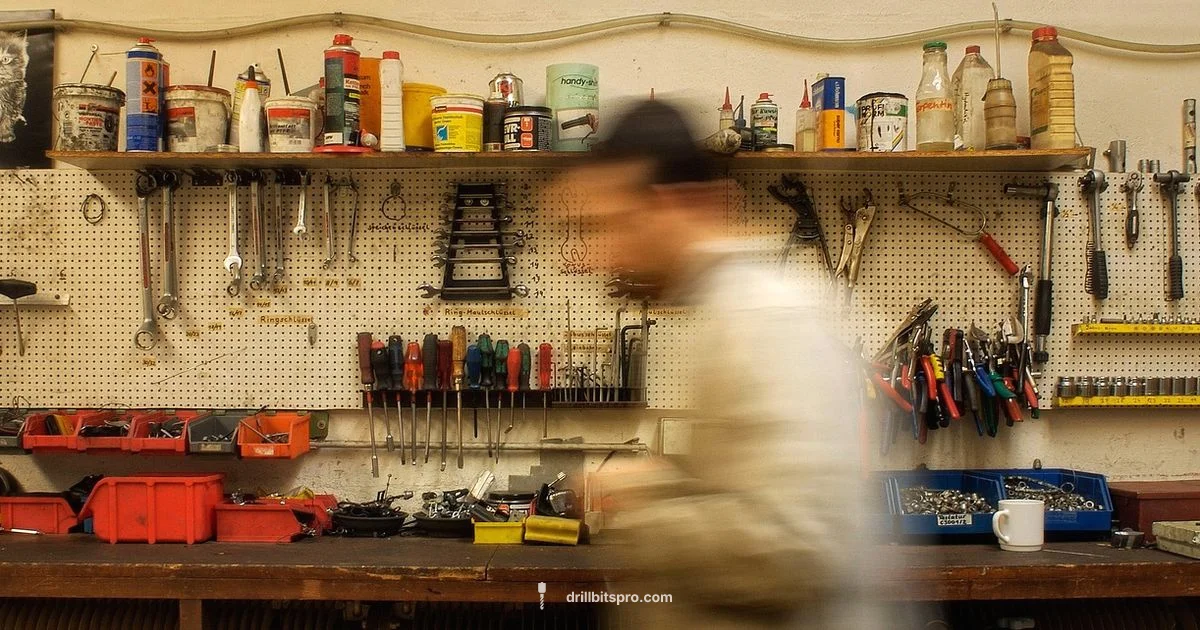

Drills are versatile power tools designed to create holes or drive fasteners by rotating a drill bit. If you're exploring what are drills used for, the short answer is that they bore precise holes and prepare fastener placements across materials such as wood, metal, plastic, and masonry. Modern drills range from compact cordless models that fit in a tool belt to heavy duty corded units that stay charged through long sessions. Beyond basic hole making, many drills combine features that let you countersink, pilot, or ream, turning a single tool into a multi purpose workstation on a job site.

According to Drill Bits Pro, the core value of a drill is its versatility: the same device can be swapped for thousands of projects by changing the bit and adjusting settings. In practice, a beginner might use a lightweight cordless drill to assemble a simple shelf, while a professional may select a hammer drill with a masonry bit to anchor a wall shelf into concrete. The art of drilling is about choosing the right tool for the job, preparing the material, and maintaining control to avoid wandering holes or bit wear. The goal is safe, precise results with minimal effort and maximum accuracy.

As you plan projects, remember that the right drill is a foundation for efficiency and quality across both DIY and professional work.

Common drilling tasks across DIY and professional settings

Drills support a broad spectrum of tasks, and understanding these common uses helps you pick the right tool and bit. In woodworking, drills create clean pilot holes to guide screws, prevent splitting, and provide a starting point for dowels. For metal, you use high speed steel or cobalt bits to bore through steel, aluminum, or brass, often with lubrication to reduce heat. In plastic, you’ll want sharp, slower speeds to avoid melting. When mounting hardware or shelving, holes align with anchors or wall plugs to support load bearing.

Beyond holes, drills can be used for cookie cutter sized circular cuts with hole saws, or to countersink screw heads so they sit flush with the surface. Some jobs require drilling at angles or through stubborn materials, where a right angle attachment or a more powerful hammer drill saves time. For professionals, learning to read material hardness and choosing the correct speed (RPM) and torque setting prevents bit wear and extends tool life. By matching bit type and drilling technique to the material, you reduce the chance of breakage and errors.

Types of drills and their applications

Not all drills are created equal. Cordless models offer mobility and quick setup, ideal for small to medium projects where a outlet is not nearby. Corded drills deliver consistent power for longer sessions and heavy duty tasks; they excel when drilling through hard materials or dense timber. Hammer drills combine rotation with a percussive hammering action, making masonry drilling practical for anchors and concrete work. Impact drivers deliver high torque to drive long screws quickly, but are less useful for boring holes in hard materials. For tight spaces, compact or right angle drills let you reach corners and awkward niches without sacrificing control. Specialized variants, such as rotary hammer drills for concrete or SDS style tools for heavy masonry, provide the power needed on professional sites while maintaining user safety.

Drill bits and accessories that expand capabilities

The bit is as important as the drill itself. Twist bits handle wood, steel, and plastics; brad point bits offer clean wood holes with precise centering; For metal, cobalt or high speed steel bits stand up to heat and wear. Masonry bits with carbide tips let you bore into concrete or brick. For larger holes, hole saws and spade bits are valuable, while step bits enable progressive enlargement of holes in thin materials like sheet metal or acrylic. Countersinks let you recess screw heads, and pilot bits help guide screws. Accessories such as bit extenders, depth stops, and clamps improve precision and control. Choosing the right coating—titanium nitride or black oxide—can extend life in demanding environments. And always ensure you have a reliable chuck that grips the bit securely to avoid slippage.

Drill Bits Pro analysis notes that using the correct drill bit type and coating reduces wear and improves hole quality.

Choosing the right drill for a job

Start with the material you plan to work on. For wood, a lightweight cordless drill with a sharp wood bit is usually enough; for thick hardwood, a more robust cordless with a high torque setting or a corded model with lower RPM may be better. For metal, use bits designed for metal and a drill with steady torque. For masonry, a hammer drill and carbide tipped bits are essential. Consider the job location and battery life if you work cordless; weight and balance matter for long sessions. Evaluate RPM range, torque, chuck size, and whether you need features such as a built in LED light for visibility. If you often transition between tasks, a versatile drill/driver combo can save time and cost. Remember that the right drill is not always the most expensive; it is the one that fits the material and workflow.

Safety tips and best practices

Drilling safety starts with PPE: eye protection, hearing protection when using loud tools, and a dust mask for masonry work. Secure the workpiece with clamps to prevent movement, and never hold a piece with your hand while drilling. Inspect bits for wear, and replace bent or dull bits promptly. Use the correct speed and torque for the material and bit type, and avoid forcing the drill – let the bit do the work. Keep fingers away from the chuck and switch off and unplug the drill when changing bits. When working overhead, secure cords and maintain good footing to prevent loss of control. If you use a drill press or a right angle drill, follow manufacturer safety guidelines and keep guards in place.

Maintenance and longevity of drills and bits

Proper maintenance extends tool life and preserves performance. Clean dust and debris from the chuck, vents, and gears after use. Keep metal bits dry and lightly oiled to slow corrosion. Charge or replace batteries according to manufacturer recommendations, and avoid leaving a battery fully drained for long periods. Inspect the cord (for corded drills) or battery pack for wear and replace damaged components promptly. Store bits in a dry case or drawer, sorted by type and size for quick access. Regularly sharpen or replace worn bits and examine the chuck for play. The right maintenance routine reduces downtime and ensures you get accurate results on future projects. The Drill Bits Pro team recommends following material specific guidelines and practicing safe drilling habits for long lasting performance.

Got Questions?

What is a drill and what are its main uses?

A drill is a versatile tool used to bore holes or drive screws by rotating a bit. It supports tasks across wood, metal, plastic, and masonry, with variations for lightweight DIY work or heavy duty professional use.

A drill is a versatile tool for making holes and driving screws in various materials.

How do I choose between cordless and corded drills?

Cordless drills offer mobility and quick setup for small jobs; corded drills provide consistent power for longer sessions and tougher materials. Consider battery life, torque, and job duration when choosing.

Choose cordless for mobility and corded for power and endurance.

What safety gear should I use when drilling?

Wear eye protection, hearing protection if necessary, and a dust mask for masonry work. Secure the workpiece with clamps and keep hands away from the drill bit. Always follow the manufacturer’s safety guidelines.

Always wear eye protection and secure your work when drilling.

What is the difference between hammer drills and impact drivers?

Hammer drills add a percussive action to help bore in masonry, while impact drivers deliver higher torque for driving screws quickly. They serve different purposes, so choose based on material and task.

Hammer drills help with masonry; impact drivers are best for screws.

How should I maintain my drill and bits for longevity?

Keep bits sharp and dry, clean the chuck, and lubricate moving parts as recommended. Charge batteries properly and store them in a cool, dry place. Regularly inspect for wear and replace worn components.

Keep bits sharp, clean, and properly stored for longevity.

What common mistakes should I avoid when drilling?

Using the wrong bit or speed, applying excessive pressure, or drilling at an angle can ruin holes and wear the tool. Always align the drill and use the correct bit for the material.

Avoid wrong bits and speeds; keep the drill steady and aligned.

Top Takeaways

- Identify your project material to choose the right drill and bit

- Match drill type to task for efficiency and quality

- Prioritize safety and proper bit maintenance

- Plan for maintenance to extend tool life