Do You Need a Special Drill Bit for Metal? A Practical Guide

Learn when metal requires a dedicated drill bit, compare HSS, cobalt, and carbide options, and follow a clear, step-by-step approach to drill clean holes safely.

Yes, in most cases you should use a bit designed for metal, especially for steel, stainless, or harder alloys. Use the right bit material (HSS for softer metals, cobalt or carbide for tougher alloys), apply cutting fluid, and start with a center punch. For best results, match the bit to the metal, adjust the drill speed, and work gradually to the final diameter.

Metal types and the right bit choices

If you’re asking the question do you need a special drill bit for metal, the short answer is often yes. Metals behave differently from wood or plastic: they conduct heat rapidly, they can work-harden if cut too aggressively, and their thickness and composition affect how a drill bit wears. For thin sheet metal and soft alloys, a standard HSS bit may run well, but for stainless steel, cast iron, or hardened steels you’ll want a tougher tip and a robust shank. Always clamp the work securely and use a center punch to create a starting point so the bit doesn’t wander. This simple preparation reduces wandering and improves accuracy from the first stroke.

Bit material matters: choosing the right tool for the job

Choosing the right drill bit material is the first decision when drilling metal. High‑speed steel (HSS) bits cover many DIY metal tasks, especially in aluminum and mild steel. For stainless or heat‑treated alloys, cobalt bits (often labeled M42) resist heat and stay sharper longer. Carbide tips are extremely hard and maintain sharpness through many cuts, but carbide bits are brittle and best used in controlled situations. For most home projects, start with HSS for softer metals and step up to cobalt for tougher jobs. Drill bit geometries—such as split-point and dual‑end tips—can also help with start-up and reduce walking.

Center punch, pilot holes, and hole location

Before you ever touch the drill, mark the hole with a center punch and a light hammer tap. The indentation keeps the bit from skidding as you begin cutting. For thicker stock, drill a small pilot hole (about 10–20% of the final diameter) first. A pilot hole reduces the amount of material the final bit must shear through at once, which improves hole accuracy and extends bit life. Always verify alignment with a straightedge or a caliper before drilling.

Lubrication and cooling: saving bits and surfaces

Metal drilling generates heat that can dull bits or gall metal. Use a light cutting fluid or oil on the bit and workpiece to reduce friction. Aluminum often benefits from light lubrication, while steel and stainless benefit more from steady cooling. If you don’t have cutting fluid, at least pause to re-lubricate every few minutes and withdraw the bit to clear chips. Lubrication is a straightforward way to improve life and performance, especially during deeper cuts.

Speed, feed, and arc: how to set the drill for metal

Drilling metal requires careful control of speed and feed. In general, metals drill better at slower speeds with steady pressure, rather than high RPMs that overheat the bit. Start with a conservative speed and apply consistent downward pressure as you feed the bit into the material. If the bit begins to smoke or the chips are hot and curl slowly, back off, pause for lubrication, and reduce pressure. For thicker sections, you may need multiple passes with increasing diameter.

Stainless steel and hardened alloys: special considerations

Stainless steel and hardened alloys are among the trickiest metals to drill. Their high heat resistance and work-hardening characteristics mean you should choose a cobalt or carbide tip and maintain a generous cooling flow. Avoid rapid plunging or side pressure that can cause the bit to bite and deflect. A slow, steady plunge with a center-punched mark yields the cleanest hole with the least wear on the bit.

Hole sizing and layout: accuracy matters

Plan hole size by selecting the final diameter first, then work through the steps to reach it. When working with metal, tolerance matters; tiny misalignments become more obvious, especially in assemblies. Use calipers to check the hole diameter and a deburring tool to remove sharp edges once the hole is complete. For precision, consider drilling from multiple passes: pilot hole, intermediate size, then final diameter, with coolant between passes.

Common mistakes and how to avoid them

Avoid dull or damaged bits by sharpening when needed and replacing worn tools. Do not rush the cut and never force a bit through metal—the risk of breakage and rebound increases with speed and pressure. Always clamp the workpiece, use marking and center punching, and maintain cleanliness of the hole area. Lastly, protect your eyes and hands; metal shavings can be sharp and hot.

Tools, accessories, and setup you’ll want

A proper drill, a metal‑rated bit (HSS, cobalt, or carbide), a center punch, clamps, cutting fluid, a deburring tool, and safety gear form the core kit. Keep scrap metal handy for test runs. Comparative practice on a scrap piece can reveal how a bit behaves before you drill the real workpiece. A stable, flat work surface minimizes movement and improves hole accuracy.

How to determine bit wear and when to replace

Inspect bits after every few holes for signs of dullness, chipping, or rounding of the tip. A worn bit cuts slowly, produces rough edges, and increases heat. If you notice reduced cutting efficiency or irregular chips, switch to a sharp bit. Proper storage and cleaning reduce corrosion and ensure bits stay sharp longer.

Safety first: setup and PPE

Always wear safety glasses or a face shield, hearing protection if using louder tools, and gloves kept away from rotating parts. Secure the work with clamps and never drill while standing off to the side. A clean, well-lit workspace and a spill-free floor reduce accidents. Follow tool manufacturers’ safety guidelines for metal drilling at all times.

Choosing a metal-bit set for DIY projects

For most DIY metal projects, a set that includes HSS and one or two cobalt bits covers a wide range of materials. If you frequently drill stainless or hardened parts, consider adding carbide-tipped bits to your kit. Look for bits with a split-point tip for easier starting and less wandering. A compact set that fits in your tool box is ideal for on-the-go projects.

Tools & Materials

- Drill bit designed for metal (HSS, cobalt, or carbide)(Choose based on metal type and thickness)

- Drill(Variable-speed preferred; ensure chuck accepts your bits)

- Center punch(Marks starting point and prevents wandering)

- Lubricant/cutting fluid(Reduces heat and prolongs bit life)

- Clamps or vise(Secure workpiece firmly)

- Safety glasses or face shield(Protect eyes from chips and debris)

- Marker or tape(Mark hole location and depth)

- Deburring tool(Finish the hole edge)

- Shop towels or waste bin(Clean up metal shavings)

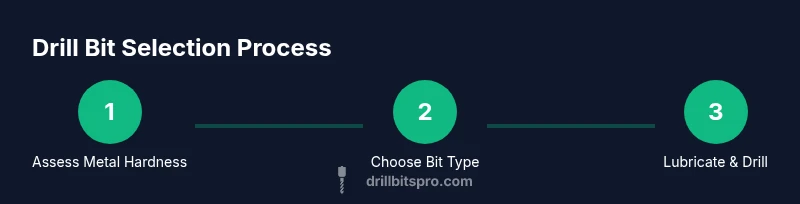

Steps

Estimated time: 45-60 minutes

- 1

Prepare and secure the workpiece

Place the metal on a flat, stable surface and clamp securely. This prevents movement that could mar the hole or cause the bit to wander. Verify the clamp won’t interfere with the drill path.

Tip: Double-check clamp positions before starting. - 2

Mark the hole location

Use a marker or center punch to mark exactly where you want the hole. A precise mark prevents drift as the drill begins cutting.

Tip: Keep marks visible by avoiding paint-over marks. - 3

Choose the bit and test on scrap

Select a bit based on metal type and diameter. Test on a scrap piece to confirm alignment and cutting behavior before touching the final workpiece.

Tip: Test run helps avoid costly mistakes. - 4

Drill a pilot hole

Start with a small pilot hole to guide the larger bit. Use light pressure and steady progress to avoid grabbing.

Tip: Pilot holes reduce final-diameter wandering. - 5

Drill to final diameter gradually

Switch to the final bit diameter in stages if needed. Pause for lubrication between passes and withdraw periodically to clear chips.

Tip: Avoid forcing the bit; let the bit do the cutting. - 6

Lubricate and manage heat

Apply cutting fluid or oil to minimize heat buildup. Heat is the enemy of sharpness and can warp thin metals.

Tip: Reapply lubrication as the cut progresses. - 7

Maintain alignment and speed

Keep the drill perpendicular to the workpiece and maintain a constant feed. If the drill binds, back off and re-lubricate.

Tip: A steady hand reduces chatter. - 8

Deburr and inspect the hole

Remove sharp edges with a deburring tool. Check hole diameter and straightness with calipers.

Tip: Deburring prevents injuries and fits better assemblies. - 9

Finish and clean up

Wipe away chips and oil; store bits clean to prevent corrosion. Return tools to their proper place for next project.

Tip: Keep a dedicated metal-bit kit for quick access.

Got Questions?

Do you need a special drill bit for metal?

Yes, for most metal work you’ll benefit from a bit designed for metal. The exact choice depends on the metal’s hardness and thickness; aluminum or mild steel often works with HSS, while stainless or hardened alloys benefit from cobalt or carbide.

Yes. For most metal drilling tasks, use a bit designed for metal, choosing cobalt or carbide for harder metals.

What is the difference between HSS, cobalt, and carbide drill bits?

HSS bits are versatile for soft metals; cobalt bits resist heat when drilling stainless or hard alloys; carbide bits stay sharp in tough materials but can be brittle. Match the bit to the metal and thickness for best results.

HSS is good for soft metals, cobalt for heat-resistant steels, carbide for the toughest metals, use the right one for your material.

Can I drill metal without lubrication?

Drilling metal without lubrication is possible on soft metals but not recommended. Lubrication reduces heat, extends bit life, and produces cleaner holes, especially on thicker or harder metals.

You can drill without lubrication on some soft metals, but it’s better to use cutting oil to keep bits sharp and holes clean.

What speeds should I use for metal drilling?

Use lower speeds for metal than for wood, and adjust based on metal hardness. Start slow, apply steady pressure, and increase only if the bit remains cool and chips flow smoothly.

Start slow and steady; adjust speed if the bit stays cool and chips flow well.

Is stainless steel harder to drill than aluminum?

Yes. Stainless is harder and generates more heat; it benefits from cobalt or carbide bits and good lubrication to prevent work-hardening and wear.

Yes, stainless is harder to drill than aluminum and needs tougher bits and lubrication.

What should I do if the bit binds or sticks?

If the bit binds, stop feeding, back out slowly, re-lubricate, and re-check alignment. Apply less pressure and let the bit cut at its own pace.

If it binds, back off, re-lubricate, and try again with gentler pressure.

Watch Video

Top Takeaways

- Choose the right bit for the metal type

- Center punch and pilot holes improve accuracy

- Lubrication reduces heat and extends bit life

- Slow speeds and steady feeds prevent damage

- Deburr holes for safe, clean finishes