What size drill bit for 1/2 tap: A practical guide

Learn how to choose the correct drill bit size for a 1/2 tap, understand pitch (coarse vs fine), and verify with trusted charts to ensure strong, clean threads.

To tap a 1/2-inch hole correctly, start by identifying the thread pitch: 1/2-13 UNC (coarse) or 1/2-20 UNC (fine). Then consult a reliable tap-drill chart or the tap manufacturer’s recommendations to choose the exact drill size. Always test the hole on scrap material, deburr, and verify fit before cutting threads in the final part.

Understanding 1/2 Tap Sizes and Pitch

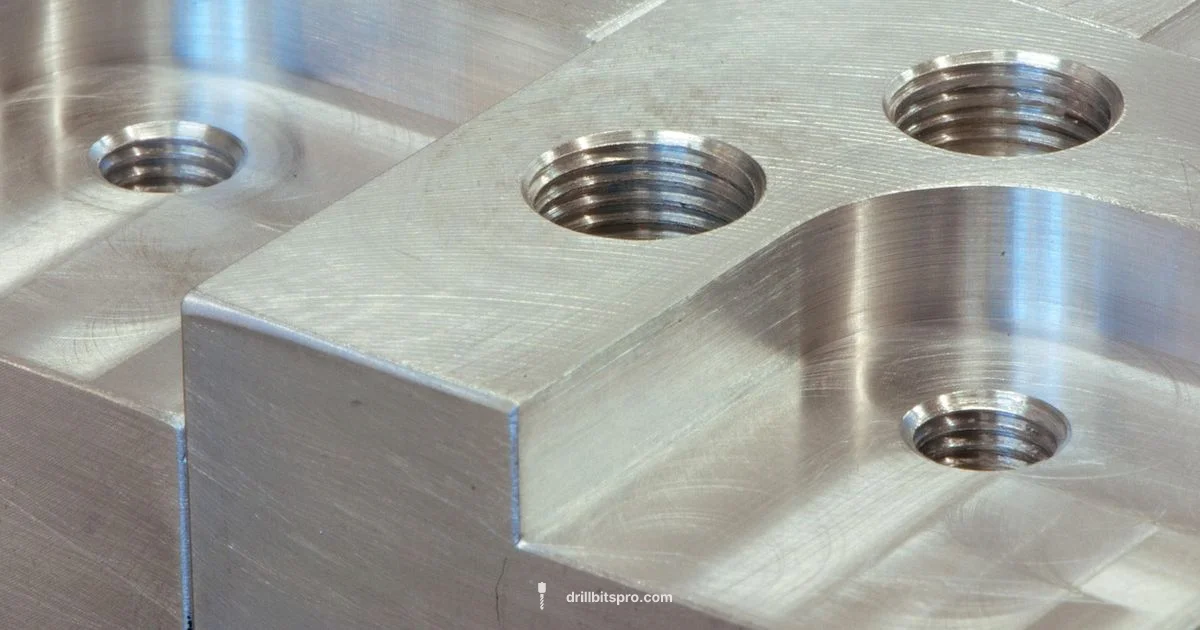

The term “1/2 tap” refers to a nominal diameter used for creating internal threads. However, the exact size of the hole you need before tapping depends on the thread pitch—how many threads per inch you plan to cut. A 1/2-inch hole can be paired with several pitches, including coarse and fine variants. The drill size you select must align with the pitch you intend to produce; using the wrong size will lead to faulty engagement, stripped threads, or poor strength. For this reason, the first step in answering the question, what size drill bit for 1/2 tap, is to confirm the desired thread pitch and the material you’re working with. Industry-standard tapping charts translate those specifications into practical drill diameters, which is why consulting a chart is standard practice rather than guessing. In short, the keyword here is precision: you’re mapping thread geometry to a specific drill diameter to achieve the right core, tooth engagement, and thread profile.

How Thread Pitch Dictates Drill Size

Thread pitch describes how tightly spaced the threads are. When you switch from a coarser pitch to a finer pitch for the same nominal diameter, you generally need a smaller pilot hole. This makes intuitive sense: more threads per inch means threads will be closer together, so the hole must be smaller to allow room for those threads to form without tearing. Conversely, a coarser pitch requires a larger hole to give the taps enough material to cut cleanly. Because the relationship between pitch and hole size is precise, the only reliable way to select the drill size is to reference a trusted chart or the manufacturer’s guidelines for the exact thread you intend to produce. Do not rely on memory or approximate numbers—use official references and confirm with a test cut on scrap material.

Reading Tap-Drill Charts: A Practical Skill

Tap-drill charts are your most important tool when deciding what size drill bit to use for a 1/2 tap. These charts list combinations of nominal size and pitch (for example, 1/2-13 UNC or 1/2-20 UNC) and pair them with the recommended drill diameter. Accessibility matters here: many charts exist in mechanical handbooks, manufacturer catalogs, and reputable online references. When you read a chart, locate your target diameter first, then follow to the corresponding pitch. If you work with unfamiliar materials, keep in mind that tool geometry and lubrication can shift the ideal size slightly. In any case, start with the chart’s recommended drill size and validate with a test hole in scrap material before proceeding to your production workpiece.

Step-by-Step Method to Size the Drill Bit

Identifying the correct drill size for a 1/2 tap starts with determining your thread pitch and then cross-referencing a trusted chart. If you don’t have a printed chart handy, many reputable sources offer downloadable references. After you locate the recommended drill size for your pitch, confirm the measurement with calipers for accuracy. Note that some charts show slight tolerances; when in doubt, pick the smaller option to avoid a hole that’s too large. In practice, you’ll align your drill bit’s diameter with the chart’s guidance and proceed to drill your pilot hole with a sharp bit and steady pressure.

Testing and Verifying Your Hole

Always validate your pilot hole before tapping. Drill a scrap hole with the chosen size, deburr, and inspect the edge for any nicks or burrs that could damage the tap. Apply a light cutting lubricant or tapping fluid to reduce friction and chip buildup. Manually run the tap in with a slow, steady motion, backing out every few turns to break and clear chips. If the threads feel binding or you observe excessive resistance, stop and reassess—either try a smaller drill size (on scrap) or switch to a different pitch.

Common Mistakes and How to Avoid Them

Common errors include guessing the drill size, drilling in the wrong spot, failing to deburr, and rushing the tapping process without lubricant. Always secure the workpiece, mark the center with a punch, and start with a pilot hole. Don’t force the tap; apply even downward pressure with occasional back-turns to break chips. Lubrication is essential, especially with harder materials; without it, taps can dull, break, or seize. If you observe chatter or poor thread form, re-check the drill size against a chart and test again in scrap.

Material and Lubrication Considerations

Different materials respond differently to tapping. Softer metals may allow a slightly larger hole without compromising thread integrity, while harder alloys can benefit from a smaller pilot hole and generous lubrication. For practice runs, test in scrap material that resembles the final workpiece. Use a light tapping fluid to reduce heat and wear, particularly in stainless steel or aluminum. Always ensure your tool is sharp and correctly aligned to prevent thread runout.

Safety, Maintenance, and Best Practices

Tapping creates significant metal chips and heat, so PPE is essential: safety glasses, gloves, and a clean workspace. Clamp the workpiece firmly to avoid movement. After tapping, clear chips thoroughly and inspect the threads with a gauge to confirm accuracy. Keep your drill bits sharp and store them properly to maintain geometry. Regularly check your tapping setup, including speed, lubricant, and torque, to extend tool life and maintain consistent results.

Final Checks Before Production

Before committing to a full production run, verify the chosen drill size with multiple scrap holes. Confirm the threads with a go/no-go gauge and test a fastener to ensure proper engagement. Re-check drill wear and lubrication effectiveness, and adjust if necessary. Consistency is the goal: repeatable results across parts rely on starting with the correct drill size and maintaining clean, deburred holes.

Tools & Materials

- Drill (handheld or drill press)(Use a speed appropriate for the material; maintain steadiness.)

- Quality twist drill bits for metal or wood(Ensure sharpness; have a spare in case of dulling.)

- Center punch(Create a dimple to prevent wandering during drilling.)

- Tap set (matching the target thread pitch)(Includes the correct tap and perhaps a bottoming/plug tap depending on depth.)

- Lubricant or tapping fluid(Reduces heat and wear; especially helpful on harder metals.)

- Tap wrench or T-handle(Provides controlled, even turning force.)

- Go/no-go gauge or thread gauge(Used to validate thread dimensions after tapping.)

- Safety gear (eye protection, gloves)(Protect from chips and sharp edges.)

Steps

Estimated time: Estimated total time: 30-60 minutes depending on material and hole depth.

- 1

Identify the thread pitch

Determine whether you’re using a coarse or fine 1/2 inch thread. This decision drives the drill size and ultimately the strength of the threaded connection. If you’re unsure, check the project specification or consult the manufacturer’s guidelines.

Tip: Document the pitch for future reference in the same project folder. - 2

Locate the recommended drill size

Consult a trusted tap-drill chart or manufacturer data to find the exact drill diameter for your chosen pitch. Cross-check units (inches) and verify that the chart matches your thread standard (UNC vs UNF).

Tip: If you don’t have a chart handy, download a reputable reference before proceeding. - 3

Mark and center punch the hole

Mark the hole position and use a center punch to create a small indentation. This helps keep the drill from wandering as you begin cutting.

Tip: Apply light taps—avoid deforming the workpiece. - 4

Drill the pilot hole

Using the chosen drill size, drill the pilot hole in a controlled manner. Maintain perpendicular alignment to the workpiece surface and clear chips frequently.

Tip: Periodically stop to verify hole depth with a drill stop or depth gauge. - 5

Deburr and clean the hole

Remove burrs from the hole entrance and deburr the hole interior to promote clean thread cutting. Wipe away chips before tapping.

Tip: A deburring tool or fine file works well for the edge. - 6

Tap the hole with lubrication

Apply a light lubricant or tapping fluid and begin turning the tap slowly in the correct orientation. Use a gentle back-turn to break chips occasionally.

Tip: Keep guiding the tap to stay aligned with the hole axis. - 7

Check progress and back out periodically

As you cut threads, back the tap out every few turns to clear debris. Periodic cleaning maintains thread quality and reduces friction.

Tip: Do not force the tap—if you encounter resistance, stop and reassess. - 8

Validate with a gauge and test fastener

After tapping, verify the thread with a go/no-go gauge and thread a test fastener to confirm fit and engagement.

Tip: If it binds, do not force; rework the hole size or pitch.

Got Questions?

What does UNC vs UNF mean for a 1/2 tap?

UNC and UNF refer to coarse and fine thread series. The pitch difference changes the recommended drill size, so always confirm the exact specification before drilling.

UNC and UNF refer to coarse and fine thread options; the pitch difference affects the drill size you should use.

Why can’t I use a standard drill size for all 1/2 taps?

Because the drill size must match the intended thread pitch to achieve proper engagement. Using the wrong size can produce weak or nonfunctional threads.

The drill size must match the thread pitch; otherwise threads may be weak or fail.

What if I don’t have access to a tap-drill chart?

Look up a reputable chart online or consult the tap manufacturer’s guide. If possible, test a few scrap holes to determine the best option.

If you lack a chart, consult the manufacturer’s guide and test on scrap pieces.

Can I rework a hole that’s too tight or too loose?

If the hole is too tight, try a slightly larger drill size on scrap material to reach the correct clearance. If too loose, you may need to re-tap with a different pitch or plug-and-re-tap.

If the hole is off, adjust using scrap tests and consider re-tapping with the correct pitch.

What safety steps should I always follow when tapping?

Wear eye protection, secure the workpiece, and use lubricant to reduce heat. Maintain clean work surroundings to avoid chips causing injuries.

Wear eye protection and secure the workpiece; keep the area clean and lubricate the tap.

Is there a formula to calculate drill size automatically?

There isn’t a single universal formula; use official charts or manufacturer guidance for each thread size and pitch. Charts translate thread geometry into drill diameter.

There isn’t a universal formula—use a chart or manufacturer guidance.

Watch Video

Top Takeaways

- Identify the pitch before selecting drill size.

- Always use a trusted tap-drill chart for accuracy.

- Test on scrap before final production.

- Deburr, lubricate, and verify with gauges after tapping.