When Drilling into Concrete: A Practical How-To Guide

Learn safe, effective methods for drilling into concrete with the right tools, bit types, and techniques. This comprehensive guide from Drill Bits Pro covers pilot holes, dust control, anchoring, and common mistakes to avoid for professional results.

To drill into concrete safely and effectively, use a hammer drill with a carbide-tipped masonry bit, start with a small pilot hole, and maintain steady pressure while cooling the bit as needed. Choose the correct diameter, use dust containment, and anchor or plug the hole as required. Follow safety guidelines and consult manufacturer instructions.

Why drilling into concrete requires careful planning

When you plan to drill into concrete, you must account for material hardness, dust generation, and the risk of bit wear. According to Drill Bits Pro, selecting the right tool and technique is essential to achieve clean holes and reliable anchors. This section explains how to assess the surface, choose the proper drill and bit, and prepare the workspace for a safe, accurate bore. You will learn how concrete consistency, moisture, and rebar presence influence your approach, and why a structured plan reduces attempts and wasted time on the job.

Concrete categories: hardness and drilling implications

Concrete is a composite material with varying hardness levels depending on aggregate, cement mix, and curing. The harder the concrete, the more stress a bit endures and the faster it can dull. Based on Drill Bits Pro research, selecting a bit with carbide tips and a robust hammer-drill action is essential for long life and good hole quality. In softer concrete, you may get away with smaller pilot holes and faster progress, but you should still follow best practices to avoid spalling and misplacement.

Tools and bits: what really works for concrete

Choosing the right tools makes the difference between a clean hole and a frustrating experience. Essential items include a hammer drill, carbide-tipped masonry bits, a tape measure and marker, depth stops or tape, and PPE such as safety glasses and a dust mask. Optional but highly recommended are a dust extraction vacuum and masking tape to prevent bit wandering. For larger holes, consider specialized carbide-tipped bits and, if needed, SDS-compatible options. Drill Bits Pro emphasizes quality over price to minimize wear and maximize control.

Setting up a safe, clean workspace

Begin by clearing the work area and placing a stable backing board or pad to prevent chipping on the opposite side. Remove loose material and ensure there is no live wiring or plumbing within the drill path. Use masking tape on the drilling site to keep the bit from wandering and to mark the exact center. Set up dust containment or a shop vac to capture dust from the hole, reducing airborne particles and improving visibility. A well-lit, ventilated space helps maintain accuracy during drilling.

Pilot holes and progressive drilling strategy

Starting with a smaller pilot hole helps guide the larger masonry bit and minimizes breakouts. Drill the pilot hole at a slow speed with steady pressure, then switch to the final bit and proceed to full depth. Drilling progressively—first the pilot hole, then the larger bit—reduces stress on the bit and the surrounding concrete. If the hole demands precision anchors, match the final depth to the anchor requirements and use a depth stop to stay consistent.

Dust control and debris management

Concrete dust is fine and can irritate eyes and lungs, so PPE is essential. Use a vacuum alongside you, keep the drill to a low speed when starting, and pause to clear dust periodically. Wetting the drill site lightly with a spray bottle can reduce dust and help with heat management, but avoid excessive moisture that could weaken the concrete or affect fasteners. Regularly inspect and replace filters on your vacuum to maintain peak dust capture.

Anchors, plugs, and load considerations

After drilling to the required depth, install the appropriate anchor or plug based on the load and substrate. For light-duty installations, plastic anchors may be sufficient; for heavy loads, use metal anchors, expansion anchors, or sleeve anchors designed for concrete. Ensure the hole diameter matches the anchor specification and that the hole is clean before insertion. Set anchors according to manufacturer recommendations, allowing any adhesive or resin to cure fully if used.

Maintenance and care for drill bits and equipment

Keep bits sharp by cleaning off concrete dust and inspecting for chips after use. Store bits in a dry environment to prevent corrosion, and sharpen carbide-tipped bits when possible using proper equipment. Periodically inspect the drill for overheating signs and allow it to cool between long drilling sessions. Cleaning the chuck and keeping a dry, organized toolbox reduces wear and improves reliability for future jobs.

Common mistakes and how to avoid them

Avoid starting with the largest bit first, neglecting dust control, or drilling without a depth stop. These mistakes can cause wandering, poor hole quality, and safety hazards. Always mark center points accurately, use the correct bit for the concrete type, and monitor heat buildup that can degrade bit life. Slow, steady progress with proper cooling yields the best results and reduces material damage.

Tools & Materials

- Hammer drill(Corded or cordless with hammer function; aim for 800-1200 RPM for masonry.)

- Carbide-tipped masonry bits(Choose diameter equal to hole size; use shorter bits for control on deep holes.)

- Tape measure and marker(Accurate center marks and depth tracking.)

- Depth stop or tape(Helps maintain consistent hole depth for anchors.)

- Safety glasses(Protect eyes from chips.)

- Dust mask or respirator(Filters fine concrete dust.)

- Hearing protection(Reduces noise exposure during drilling.)

- Masking tape(Prevents bit wandering on center marks.)

- Dust extraction vacuum (optional)(Improves dust control and visibility.)

Steps

Estimated time: 60-120 minutes

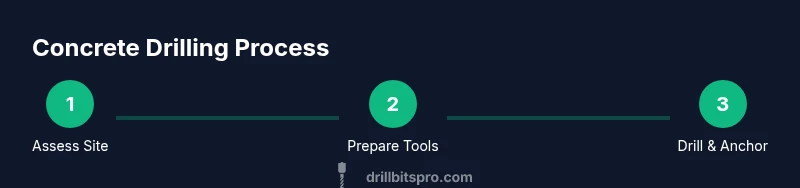

- 1

Assess site and prepare workspace

Clear the area, ensure no utilities are in the drill path, and mark the center with precision. Set up dust control and lighting to maintain visibility. Verify anchor locations align with structural requirements.

Tip: Clamp or secure the workpiece if possible to minimize movement. - 2

Choose bit size and type

Select a carbide-tipped masonry bit that matches the hole size required by the anchor. Use a pilot bit if recommended for the final hole to improve accuracy.

Tip: Keep spare bits on hand to avoid delays. - 3

Mark and pilot drill

Place masking tape at the drilling point. Drill a small pilot hole at low speed to guide the larger bit and reduce wandering.

Tip: Apply light, steady pressure; avoid pushing hard at the start. - 4

Drill full-depth holes

Switch to the final masonry bit and drill to the required depth using the depth stop. Maintain a steady pace and water when appropriate to cool the bit and reduce dust.

Tip: Pause to clear dust and check depth frequently. - 5

Cool and clean the hole

Pause to blow out or vacuum dust from the hole. Recheck depth and ensure walls are clean for anchor seating.

Tip: Never force the bit; if resistance occurs, back out and re-center. - 6

Install the anchor or plug

Insert the anchor and follow manufacturer guidelines for setting or curing. For resin-based anchors, follow cure times before applying load.

Tip: Wipe away excess material to guarantee a clean seating surface. - 7

Inspect and test

Check the hole for cleanliness and make sure anchors seat firmly. Apply light load to verify holding strength before final assembly.

Tip: If an anchor spins, reset or switch to a larger size as needed. - 8

Finish and cleanup

Remove debris, store tools properly, and document any deviations from plan for future reference. Respect safety rules even after the job is done.

Tip: Clean tools promptly to extend bit life.

Got Questions?

What bit should I use for concrete drilling?

Use a carbide-tipped masonry bit designed for concrete; match the bit size to the hole and anchor. For larger holes, consider specialized bits.

Carbide-tipped masonry bits are best for concrete; pick the size to fit your anchor and drill progressively.

Why is dust control important when drilling concrete?

Concrete dust is fine and can irritate the respiratory system; use a vacuum or dust collection and wear PPE to protect eyes and lungs.

Concrete dust can irritate you, so use a vacuum and wear PPE.

Can I drill large holes without a hammer drill?

A hammer drill or rotary hammer is strongly recommended for concrete; without impact, holes will take much longer and wear out bits quickly.

Yes, you should use a hammer drill or rotary hammer for concrete to save time and reduce wear.

How deep should I drill for a standard anchor?

Drill to the depth specified by the anchor manufacturer, plus any resin or adhesive cure requirements. Use a depth stop to maintain accuracy.

Drill to the anchor depth recommended by the manufacturer and allow for curing if needed.

Is it safe to drill near electrical or plumbing?

Always verify you are not hitting hidden utilities. Use a stud finder or utility locator, and avoid drilling in areas with unknown lines.

Check for hidden pipes or wires before drilling and use professional locators.

What maintenance does a masonry bit require?

Keep bits clean, dry, and sharp. Inspect for chips and replace worn bits to maintain hole quality.

Keep masonry bits clean and sharp for best results.

Watch Video

Top Takeaways

- Drill with the correct bit and tool for concrete.

- Pilot holes and progressive drilling reduce wear and breakouts.

- Dust control and PPE are essential for safety and accuracy.

- Anchor selection should match load and substrate.