How to Get Drill Bit Into Drill: A Practical Guide

Learn how to insert a drill bit into a drill safely and correctly. This comprehensive guide covers chuck types, bit sizes, and troubleshooting from Drill Bits Pro.

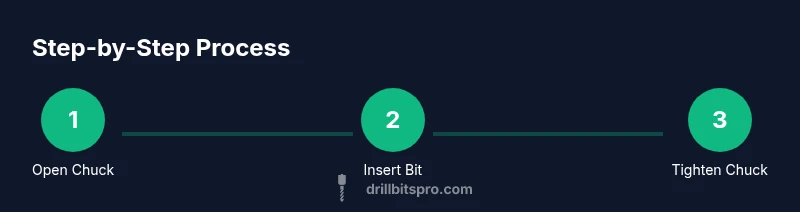

To get the drill bit into the drill, first unplug the tool or remove the battery. Open the chuck jaws fully, insert the bit so the cutting edge sits against the back of the chuck, and tighten until it cannot move. Use the correct bit size for your chuck (commonly 1/16" to 1/2"). According to Drill Bits Pro, fast, steady tightening prevents wobble.

How to get drill bit into drill: Understanding chucks and bit types

Bits are secured in the drill by the chuck, which comes in several styles. The most common are keyed chucks and keyless chucks, with round shanks that fit standard openings or hex shanks for quick-change systems. Bit shanks must match the chuck's capacity; forcing a larger shank into a too-small opening can damage both bit and chuck. The Drill Bits Pro team notes that choosing the correct match reduces vibration, increases precision, and extends tool life. When you insert a bit, you’re ensuring the shank sits squarely against the chuck’s inside back, with the cutting edge aligned along the intended centerline. A misaligned or loose fit leads to wobble, irregular holes, and accelerated wear, so take a moment to confirm compatibility before turning on the drill.

Understanding chuck types and bite sizing

Keyed chucks use a separate tool (the key) to tighten, while keyless chucks rely on the user’s grip and a friction mechanism. For hex shanks, ensure your chuck can grip the flat faces securely; for round shanks, check that the opening diameter accommodates the shank with a snug tolerance. Always consider the bit material (high-speed steel, carbide-tipped, masonry) and the task at hand, since different bits demand different chuck handling to prevent slippage during impact or drill modes. As you gain experience, you’ll learn to quickly gauge whether the bit will seat correctly based on its shank type and the chuck’s opening.

Note: Always inspect the chuck for any nicks or debris before seating a bit. A clean chuck bite greatly improves seating reliability and reduces the risk of the bit popping free during drilling.

Tools & Materials

- Drill or cordless drill(Ensure battery is charged or power cord is unplugged before assembly)

- Appropriate drill bit(Match shank type and diameter to your chuck size)

- Chuck key (for keyed chucks)(Keep within easy reach; optional for keyless chucks)

- Safety glasses(Protect eyes from chips and dust)

- Work surface(Stable, uncluttered workspace)

- Cleaning cloth(Wipe away dust and chips after seating)

Steps

Estimated time: 10-25 minutes

- 1

Power off and disconnect

Unplug the drill or remove the battery to prevent accidental starts. This simple safety step protects you as you handle the chuck and bit, reducing the risk of injury during the seating process.

Tip: Always verify power is off with a quick toggle before proceeding. - 2

Open the chuck jaws

Fully open the chuck jaws to their maximum width so the bit can seat properly. If you have a keyed chuck, insert the key and turn to open the jaws wide; for a keyless chuck, twist the outer ring to the open position.

Tip: While opening, gently wiggle the chuck to feel for smooth movement and remove any debris. - 3

Insert the bit and center it

Hold the bit near the shank and push it into the chuck hole until the bit sits centered and straight. The back of the shank should rest against the inner back of the chuck; avoid angles that would seat the bit off-center.

Tip: If the bit won’t seat straight, remove it, clean the chuck, and try again. - 4

Tighten the chuck securely

For keyed chucks, use the chuck key to snugly tighten the jaws around the bit. For keyless chucks, grip the ring firmly and rotate until the bit can no longer rotate. Do not over-tighten, which can damage the chuck and shorten its life.

Tip: Double-check that the bit is as far back as the chuck allows and that the jaws grip all the way around the shank. - 5

Test the grip

Gently tug the bit to confirm it’s secure. If there is any movement, readjust the bit position and re-tighten. A good grip prevents slippage during drilling and is critical for accuracy.

Tip: If the bit slips, stop and re-seat rather than forcing a retry. - 6

Check alignment and test on scrap

Hold the drill so the bit is perpendicular to the test surface and run at a low speed on scrap material. Observe if the bit tracks straight and remains stable before you begin the real cut.

Tip: Use a center punch or guide to help keep the bit on track during the first contact. - 7

Proceed with drilling with caution

Begin drilling slowly, applying steady pressure while maintaining a clean feed rate. Listen for unusual sounds and watch for heat buildup; stop if you notice anything abnormal and recheck the seating.

Tip: Let the tool do the work; don’t force the bit through the material. - 8

Shutdown and inspect

When finished, power off, remove the bit, and inspect the chuck and bit for wear or debris. Clean the chuck and store the bit properly to preserve seating quality for next use.

Tip: Wipe the bit with a dry cloth and store in a protective case to prevent damage.

Got Questions?

Can I insert any drill bit into any chuck?

Bits vary by shank size and chuck type. Always verify that the bit shank matches the chuck’s capacity and that the chuck type (keyed vs keyless) is appropriate for the bit. Forcing a mismatched bit can slip or damage the chuck.

Bits vary by shank size and chuck type, so always check compatibility before inserting.

What if the bit won’t seat fully in the chuck?

A bit that won’t seat usually indicates a mismatch or a dirty chuck. Clean the jaws, recheck the bit size, reinsert, and try again. If it still won’t seat, try a different bit within the chuck’s range.

If it won’t seat, clean the chuck and try again, or switch to a different bit.

Should I use a keyless or keyed chuck?

Keyed chucks provide a strong grip with the chuck key; keyless chucks rely on friction. Either works if you tighten fully and verify the bit is secure before drilling.

Keyed or keyless both work if you tighten properly.

How do I know the chuck size?

Check the chuck markings or measure the maximum jaw opening. Sizes commonly indicate the largest grip range; always ensure your bit shank fits comfortably within that range.

Check the jaw opening or markings to know size.

What safety steps should I follow?

Always unplug or remove the battery, wear safety glasses, and keep hands clear of the chuck while tightening. Safety first reduces risk of injury during seating.

Unplug, wear eye protection, and keep hands clear.

Can I use a metal drill bit in wood and vice versa?

Bit type matters for material; ensure you use the appropriate bit (e.g., masonry, wood, metal). This choice affects performance and safety.

Use the right bit type for the material.

Watch Video

Top Takeaways

- Verify chuck compatibility before inserting any bit.

- Unplug the drill before handling.

- Match bit shank to the chuck size.

- Tighten securely and test the grip.

- Inspect chuck and bit after use.