Drill or Impact Driver for Drywall: A Practical Comparison

A data-driven comparison of drill vs impact driver for drywall projects. Learn when to drill holes, drive screws, and optimize your drywall work with practical guidance from Drill Bits Pro.

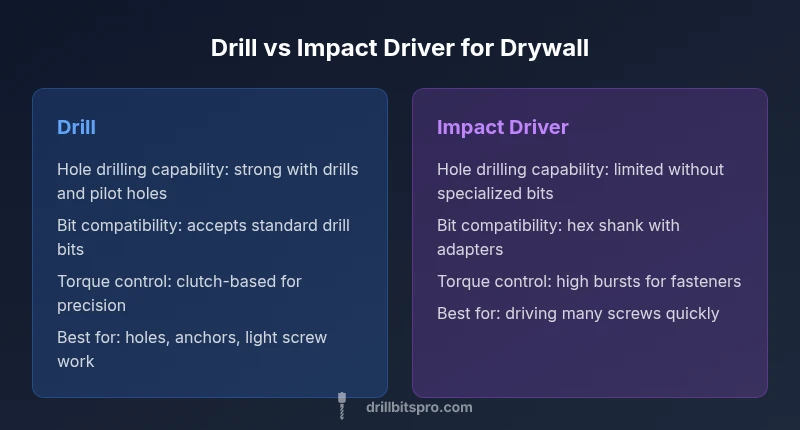

When deciding between a drill or an impact driver for drywall projects, the better choice depends on the task: drills excel at making clean pilot holes and handling light screw driving with clutch control, while impact drivers accelerate high-volume fastener work and deliver strong torque without cam-out. In practice, most drywall tasks benefit from using both tools together: a drill for holes and anchors, and an impact driver for a fastener-heavy phase. According to Drill Bits Pro, understanding the core differences helps you reduce wall damage and improve finish quality.

Understanding drywall and the role of power tools

Drywall is a relatively soft substrate that rewards careful tool use. When deciding between a drill or impact driver for drywall, you must consider notch-specific tasks like drilling holes for outlets or anchors and driving many screws for securing studs or fasteners. The right tool choice minimizes wall damage, preserves paper face, and speeds up work without sacrificing accuracy. The Drill Bits Pro team emphasizes that a balanced approach—having both a drill and an impact driver on hand—yields better results than relying on a single tool for every job. By recognizing how drywall responds to torque, vibration, and gripping force, you can tailor your technique to the material and achieve cleaner, crisper lines around openings and mounts.

In most drywall projects, the drill is used first to establish pilot holes or to bore clearance holes for anchors. An impact driver then takes over for rapid screw driving, producing strong fastenings with less effort. The goal is to minimize tearing, prevent overdriving, and maintain consistent depth across fixtures. This foundational guidance sets the stage for deeper comparisons and practical workflows that follow in this article.

headingLevelOverride":1

anchor":false},{

Comparison

| Feature | Drywall Drill | Impact Driver |

|---|---|---|

| Hole drilling capability | Best with drill bits and controlled speeds; ideal for pilot holes and outlets | Limited; primarily designed for driving fasteners; drilling requires appropriate bits and technique |

| Bit compatibility | Accepts standard drill/driver bits via chuck; easy to swap bits | Accepts hex-shank driver bits; often paired with adapters for different bits |

| Torque and control | Clutch-based control enables precise torque for screws; reduces wall damage | Impact mechanism provides high torque bursts; great for fasteners but can overdrive if not controlled |

| Speed range | Variable speeds; good for drilling and light screw work | High torque bursts; optimize for quick screw driving, less ideal for drilling large holes |

| Size and weight | Typically heavier when used with longer bits; balanced for drilling tasks | Compact and light; excellent in tight spaces but can feel fatiguing with long sessions |

| Best for drywall tasks | Hole drilling, pilot holes, and anchor prep | Driving many screws quickly, especially repetitive fastening |

| Price range | Generally affordable and widely available | Typically higher upfront cost; specialized tool for fastening |

What's Good

- Versatility across drilling and light screw driving

- Precise torque control with clutch settings

- Wide bit compatibility and common availability

- Lower upfront cost for basic kits

Negatives

- Drill can underperform at high-speed screw driving or when clutch is mis-set

- Impact driver can overdrive screws if not careful or if bits aren’t suited for drywall

- Changing between drill bits and driver bits slows progress for mixed tasks

- Some drywall projects benefit from owning both tools for maximum efficiency

Use a drill for holes and pilot drilling, and an impact driver for high-volume fastening; the combined approach delivers the best drywall results.

Drywall work benefits from tool specialization: drills handle holes with control, while impact drivers accelerate screw driving. If you must choose one, pick a drill for maximum versatility, then add an impact driver when fastening becomes the dominant task. Drill Bits Pro’s guidance emphasizes matching task to tool to preserve drywall integrity.

Got Questions?

Is an impact driver better for drywall screws than a drill?

For many drywall screwing tasks, the impact driver is faster and can reduce hand fatigue. However, use proper bit selection and set the clutch to avoid overdriving and damage to the drywall. A drill with a clutch remains a strong alternative when precision is critical.

Yes, for fast screw driving, the impact driver often wins—but use the clutch and the right bit to avoid overdriving.

Can I drill holes with an impact driver?

Impact drivers are primarily for driving fasteners, not drilling holes. They can bore small holes with appropriate bits, but they perform best when paired with a drill for larger or more precise hole work.

You can use some bits with an impact driver, but a drill is usually better for holes.

What drywall-specific bits do I need?

Drywall work benefits from standard twist bits for pilot holes, spade bits for larger openings, and anchors designed for drywall. Keep a few sizes on hand and choose bits compatible with your drill and driver. Always confirm bit compatibility with the tool’s chuck or hex shank.

Keep a small set of drywall-friendly bits and anchors ready for quick changes.

Should I predrill drywall before driving screws?

Predrilling can help prevent cracking and ensure consistent screw seating, especially near edges or when using longer fasteners. Use a pilot hole to guide the screw and avoid tearing the paper surface.

Yes, pilot holes can help prevent wall damage and ensure proper screw depth.

Are cordless tools sufficient for drywall projects?

Cordless drills and impact drivers are widely capable for typical drywall tasks. Choose a model with enough torque, decent battery life, and a comfortable grip to keep control during longer sessions.

Cordless tools can handle most drywall tasks well, with battery life and comfort as key factors.

What common mistakes should I avoid in drywall driving?

Avoid over-tightening, which can crush anchors or strip drywall screws. Use the correct bit, a steady pace, and maintain perpendicular alignment to the wall to prevent slippage and damaged edges.

Keep steady pace and avoid overtightening to prevent wall damage.

Top Takeaways

- Choose the drill for holes and pilot openings

- Use the impact driver for fastener-heavy phases

- Always set the clutch and speed to suit drywall

- Have a variety of bits ready for quick swaps

- Practice safe handling to minimize wall damage