Why Impact Driver Over Drill: A Practical Comparison

An analytical, side-by-side guide showing when to use an impact driver versus a drill, with torque, speed, ergonomics, and cost considerations for DIYers and professionals.

If you're asking why impact driver over drill, the short answer is that impact drivers deliver higher torque and lower cam-out for fastener driving, while drills excel at precision drilling. For most DIY and professional tasks, choose based on whether you need fastener performance or holes; in many setups, both tools are essential.

Why the debate matters for every toolbox

Understanding the core distinction between an impact driver and a drill helps you optimize your workflow and protect components. The question of why impact driver over drill isn’t about one tool being universally better; it’s about matching the tool to the task. The Drill Bits Pro team emphasizes this practical lens: for driving fasteners with minimal effort and reduced cam-out, an impact driver often outperforms a standard drill. Conversely, when the goal is precise hole creation or drilling into tougher materials, a drill’s chuck and speed range offer flexibility that an impact driver cannot easily replicate. By recognizing this fundamental difference, you’ll reduce tool fatigue, prevent stripped screws, and extend the life of your bits and fasteners. In short, the correct tool depends on the job at hand, not on a single万能 solution.

Core mechanical differences that drive the decision

At a high level, an impact driver uses a rotating anvil paired with a hammering action to deliver bursts of torque. This design minimizes cam-out and allows you to drive longer fasteners with less effort, which is why many professionals cite the question of why impact driver over drill as a matter of task alignment. A drill, especially a drill/driver or hammer drill, relies on a continuous rotation with a clutch that controls torque. Drills excel at drilling holes and handling larger bit diameters, but they rely on friction grip rather than impulse torque. In practice, this means you’ll see more cam-out in screws when using a regular drill without a proper bit, whereas an impact driver mitigates that problem through its percussive action.

Torque, speed, and control: what to measure when choosing

Torque and speed are the two most critical performance metrics that influence the choice of why impact driver over drill. Impact drivers typically offer higher torque at lower rotational speeds and use hex shank bits that reduce slipping. Drills provide adjustable speeds and a wider range of bit sizes, which is essential for precision work. When you’re fastening into hardwoods or metal studs, the impact driver’s torque helps you reach depth quickly, while a drill’s consistent rotation is advantageous for clean pilot holes and clean driving in delicate materials. The best decision hinges on the type of material, desired finish, and whether you value speed or precision more.

Practical scenarios: when to pick each tool

A common real-world test for why impact driver over drill is seen in fastener-heavy assemblies—decking, framing, or cabinet installation. For these tasks, the impact driver’s impact blows help seats settle faster and reduce your wrist strain. For hanging a shelf or drilling into drywall, a drill offers more control and a cleaner start. If you routinely switch between screws and holes in the same project, you’ll often benefit from owning both tools and choosing between them based on the immediate requirement. In such cases, thinking in terms of task compatibility rather than tool superiority is the most reliable strategy.

Ergonomics, battery life, and long-term value

Ergonomics and battery performance influence the long-term value of either tool. An impact driver is typically more compact and lighter when considering the torque delivered, which reduces fatigue during long sessions of driving fasteners. Drills can be bulkier with larger chucks, but they offer versatility through a broader bit ecosystem, which can justify a higher total cost of ownership if you frequently switch between drilling and driving. Drill Bits Pro’s analysis notes that the best investment is a balanced kit: a compact impact driver paired with a versatile drill and a solid set of bits. This approach addresses the core question of why impact driver over drill by combining strengths from both categories.

Bit compatibility and maintenance: practical tips

Hex shank bits work seamlessly with impact drivers, while drills accept a range of chuck-based bits. To maximize longevity and minimize wear, always use the correct bit type and ensure proper seating before applying torque. Regularly inspect bits for bending or dull edges and replace worn bits promptly. Proper maintenance reduces the risk of cam-out and improves the overall performance of both tools, supporting the case for why impact driver over drill when the job involves driving fasteners with minimal effort.

Battery ecosystem and charging habits

A major practical consideration is the battery platform. Keeping a shared battery system between your impact driver and drill can dramatically improve workflow efficiency and reduce downtime. If you already own one brand’s 20V or 18V platform, you can swap batteries between tools, which makes an investment in both tools more efficient. Drill Bits Pro’s experience indicates that battery management—charging cycles, storage, and temperature control—has a meaningful impact on performance consistency and tool longevity. When evaluating why impact driver over drill, consider not just the tool, but the entire energy ecosystem that supports consistent performance.

Safety guidelines and best practices

Both tools demand safe operation. When using an impact driver, keep fingers away from the fastener head and use the correct bit length to prevent kickback. For drills, secure the workpiece and use pilot holes to control the entry path. Understanding the differences in torque delivery helps you apply the right technique and maintain control, especially on projects with dense materials. Emphasize eye protection, gloves when handling sharp edges, and a steady stance to ensure safe, productive operation across both tool types.

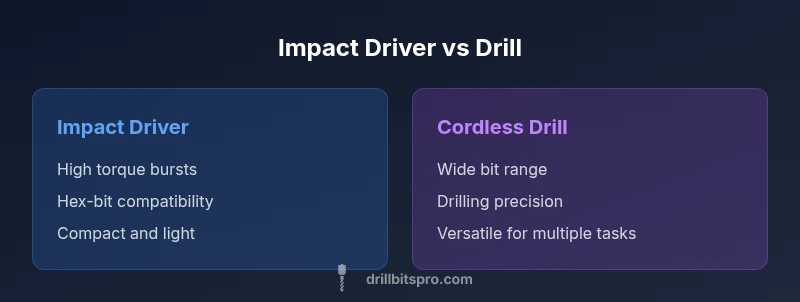

Comparison

| Feature | Impact Driver | Cordless Drill |

|---|---|---|

| Torque & cam-out | High torque with percussive bursts, minimizes cam-out | Lower immediate torque with continuous rotation |

| Chuck/Bit system | 1/4" hex quick-change bits, hex shank | Adjustable chuck (usually 1/2"), accepts various bits |

| Best for | Driving screws, bolts, and heavy fasteners | Drilling holes, pilot holes, and mixed tasks |

| Weight & size | Typically compact and lighter for high-torque tasks | Often larger due to chuck and housing |

| Speed range | Lower no-load speeds with high torque bursts | Broader speed range for drilling and driving |

| Versatility | Specialized for fasteners; some models support impact settings | Widely versatile for drilling and light driving |

| Maintenance & life | Bit wear depends on impact use; hex bits are robust | Chuck maintenance and bit wear with regular drills |

| Price range | Similar platform pricing; depends on kits | Typically similar or slightly higher for feature-rich models |

What's Good

- High torque for fastener driving with less effort

- Reduced cam-out compared to standard drills

- Compact design aids overhead and tight spaces

- Shared battery ecosystems improve overall efficiency

- Fast setup with hex-bit systems and quick-change bits

Negatives

- Limited drilling capability compared to drills

- Hex-bit dependence can limit some applications

- Less ideal for precision drilling without pilot holes

- Some models can be pricier when kits are expanded

Impact driver generally excels for fastening; drill remains essential for holes

Opt for an impact driver when you drive many fasteners or work in tight spaces. Choose a drill when you need versatile hole-making and broad bit compatibility. In most setups, a balanced pair is ideal.

Got Questions?

What is the main difference between an impact driver and a drill?

An impact driver delivers high torque in short bursts to drive fasteners with less effort, reducing cam-out. A drill provides continuous rotation with adjustable speed for drilling holes and driving with greater versatility.

The main difference is torque bursts versus continuous rotation. Impact drivers are great for fasteners; drills are best for holes.

Can I use an impact driver for drilling holes?

Impact drivers are not ideal for precision drilling due to their design. For clean holes, a drill is recommended, though some users may bore pilot holes with an impact driver using specialized bits.

Impact drivers are not the go-to tool for holes; use a drill for that.

Do I need both tools for most home projects?

For most home projects that involve fasteners and drilling, having both tools is beneficial. The impact driver speeds up screw driving, while the drill handles hole-making and versatile tasks.

Yes—having both makes projects faster and more flexible.

What bits work best with an impact driver?

Hex shank driver bits (1/4 inch) are standard for impact drivers, with socket adapters for certain jobs. Regular twist bits are less common unless using a drill with a hex adapter.

Hex-bit driver bits are your best bet with impact drivers.

Are there safety concerns when using these tools?

Wear eye protection and ensure workpieces are secure. Avoid over-torquing fasteners and maintain proper stance to control kickback and torque reactions.

Always protect your eyes and keep a firm grip on the tool.

How should I maintain batteries across tools?

Store batteries at moderate temperatures, avoid complete discharges, and rotate usage to prevent uneven wear. A shared battery platform helps maintain performance across tools.

Keep batteries warm, charged, and swapped between tools when possible.

Top Takeaways

- Prioritize task-specific performance over general claims

- Maintain a shared battery strategy to maximize efficiency

- Keep both tools if your projects require both drilling and driving

- Use hex bits with impact drivers for best results

- Protect user safety with proper PPE and proper technique