What Drill for 3/8 Tap: A Practical Guide

Learn the correct pilot hole size for a 3/8 tap, how to read tapping charts, and a step-by-step process to drill, tap, and verify threads with confidence.

To create a clean 3/8-16 threaded hole, start with a pilot hole drilled to the tapping size recommended for your material. According to Drill Bits Pro, the exact size depends on the material, thread form, and whether you’re chasing a max or standard engagement. Always consult a tapping drill chart or the tap manufacturer’s guidance to choose the correct pilot hole, then proceed with lubrication and careful threading.

Understanding 3/8 Tap Sizes and Drill Size

A 3/8 tap refers to the nominal diameter of the threaded hole, not the drill bit itself. When you drill for tapping, the drill size is a pilot hole that will shape the eventual internal threads after cutting. The specific drill size you select depends on the thread form (UNC vs UNF), the minor diameter of the tap, and the material you’re machining. In practice, you want a drill that yields proper thread depth and pitch engagement without excessive material removal or binding. The right size ensures clean threads, reduces the risk of tap breakage, and provides consistent bolt fit. The Drill Bits Pro team emphasizes using published tapping drill charts or manufacturer recommendations because even small deviations can affect thread quality. If in doubt, start with the chart’s conservative option and test on scrap material before committing to a critical part.

Understanding 3/8 Tap Sizes and Drill Size

A 3/8 tap refers to the nominal diameter of the threaded hole, not the drill bit itself. When you drill for tapping, the drill size is a pilot hole that will shape the eventual internal threads after cutting. The specific drill size you select depends on the thread form (UNC vs UNF), the minor diameter of the tap, and the material you’re machining. In practice, you want a drill that yields proper thread depth and pitch engagement without excessive material removal or binding. The right size ensures clean threads, reduces the risk of tap breakage, and provides consistent bolt fit. The Drill Bits Pro team emphasizes using published tapping drill charts or manufacturer recommendations because even small deviations can affect thread quality. If in doubt, start with the chart’s conservative option and test on scrap material before committing to a critical part.

Choosing the Right Drill Bit Type

Not all drill bits are created equal for tapping. High-speed steel (HSS) bits are versatile and inexpensive, making them a reliable default for most metals and plastics. For hard materials like stainless steel, a cobalt or carbide-tipped bit can resist wear longer, though it tends to cost more. In softer metals such as aluminum, a sharp HSS bit reduces burrs and gear up for a smoother tapping operation. When drilling through a thick workpiece, a split-point or self-centering bit helps start the hole accurately and minimizes wandering. Always keep the bit sharp and oriented perpendicularly to the work surface to avoid misalignment. Lubrication during drilling is optional but reduces heat buildup and can improve hole quality, especially in tougher materials.

Choosing the Right Drill Bit Type

Not all drill bits are created equal for tapping. High-speed steel (HSS) bits are versatile and inexpensive, making them a reliable default for most metals and plastics. For hard materials like stainless steel, a cobalt or carbide-tipped bit can resist wear longer, though it tends to cost more. In softer metals such as aluminum, a sharp HSS bit reduces burrs and helps achieve a smoother tapping operation. When drilling through a thick workpiece, a split-point or self-centering bit helps start the hole accurately and minimizes wandering. Always keep the bit sharp and oriented perpendicularly to the work surface to avoid misalignment. Lubrication during drilling is optional but reduces heat buildup and can improve hole quality, especially in tougher materials.

How to Determine the Correct Pilot Hole for a 3/8-16 Tap

The safe way to pick the pilot hole is to consult a tapping drill chart specific to your thread form (3/8-16 UNC). If you don’t have the chart handy, measure the minor diameter of the intended tap and compare it with a reputable tapping chart to identify the closest recommended hole size. Use calipers to verify the diameter and ensure the drill will produce the proper engagement for full thread depth. Always drill perpendicular to the surface and deburr the hole after drilling to prevent chips from binding the tap. Lubrication is crucial during tapping and can greatly improve thread quality and tool life. After tapping, test the hole with the mating bolt to confirm a clean, full thread.

Practical Drill Size Guidelines for Common Materials

Material choice drives the final drill size; there isn’t a one-size-fits-all number you can memorize. The recommended tapping size is listed in charts published by drill manufacturers and engineering handbooks, and your material will determine whether you pick a slightly smaller or a slightly larger pilot hole. For harder metals, start with the smaller end of the chart and proceed with steady pressure; for softer metals, you may be able to go a touch larger while maintaining good thread engagement. Plastic occasionally requires extra care to avoid cracking; run a shallower hole and use generous lubrication. The most reliable approach is to consult a tapping drill chart for 3/8-16 UNC and confirm with trial holes on scrap material before working on a critical part.

Tools and Safety for Drilling and Tapping

Before you begin, assemble a stable workstation with a robust clamp and a flat, secure surface. Wear safety glasses, and use gloves as needed to handle sharp metal chips. Use a center punch to mark your drill point and drill with a slow, steady feed to maintain control. Lubrication reduces heat and extends tool life; it’s especially important when tapping steel or stainless. Maintain perpendicular alignment between the drill and workpiece, and stop periodically to clear chips. A tapping guide or jig can help keep the tap aligned, reducing the chance of cross-threading. After tapping, clean the hole and inspect the threads with a bolt gauge or thread gauge to confirm proper engagement.

Common Mistakes and Troubleshooting

Common mistakes include starting without securing the workpiece, wandering the drill bit, and rushing the tapping operation. Always check hole alignment, keep chips cleared, and back off the tap after a few turns to break chips. A dull bit or insufficient lubrication can cause heat buildup and broke taps. If the tap binds, stop, back it out, re-lubricate, and re-align before continuing. If a tap breaks, do not force the remainder; use a proper extract or consult a professional. When in doubt, practice on scrap stock first to dial in your technique.

Authority Sources

For reference, consult tapping size charts from reputable sources and standards bodies. Recommended reading includes official material from industry standards and university extension programs. Quick check: OSHA safety guidelines and basic metalworking sources can provide general safety context, while engineering handbooks cover tapping sizes and procedures in detail. Always verify sizes with manufacturer charts and test on scrap before final production.

Tools & Materials

- High-speed steel (HSS) drill bit(Sharp, properly sized for the tapping chart recommendation)

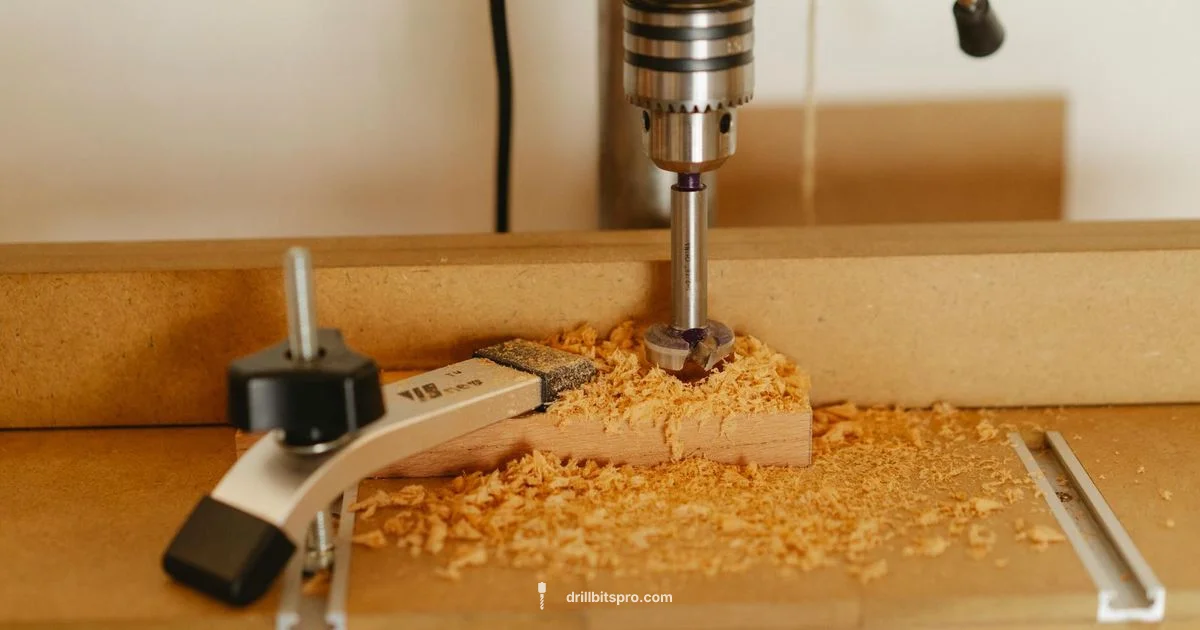

- Corded or cordless drill / drill press(Maintain perpendicular alignment with the workpiece)

- Center punch(Marks exact drill point to prevent wandering)

- Lubricant or cutting oil(Reduces heat; improves thread quality)

- Tap wrench and 3/8-16 tap(Hand tapping or machine tapping setup)

- Calipers or drill gauage(Verify hole diameter against chart (optional but helpful))

- Deburring tool or file(Deburr the hole before tapping)

Steps

Estimated time: 45-75 minutes

- 1

Prepare and secure the workpiece

Clamp the part securely in a vise or fixture. Mark the drill point with a center punch to prevent the bit from wandering. Ensure the surface is clean and free of debris before you begin.

Tip: Use a drill press or hole jig to maintain perfect perpendicularity. - 2

Identify the tapping drill size using a chart

Consult a tapping drill chart for 3/8-16 UNC. If you don’t have the chart handy, measure the tap’s minor diameter and compare to a trusted reference. Choose the closest recommended hole size for your material and thread form.

Tip: Double-check the chart with a scrap piece to confirm the match. - 3

Drill the pilot hole

Set your drill to a slow speed and drill perpendicular to the workpiece. Apply steady pressure and avoid pushing too hard to prevent bit binding. Stop when you reach the required depth and remove chips.

Tip: Light lubrication during drilling reduces heat and helps maintain hole quality. - 4

Deburr and clean the hole

Remove burrs and flush chips from the hole. Deburring helps ensure the tap starts true and reduces the chance of cross-threading. A small countersink can help if the edge is sharp.

Tip: Blow out chips with compressed air or brush with a small, stiff brush. - 5

Lubricate and start tapping

Apply cutting oil or recommended lubricant on the tap. Start the tap by hand to keep alignment, then turn gradually with steady pressure. Back off every few turns to break chips and prevent binding.

Tip: Keep the tap perpendicular; avoid forcing it through a tight spot. - 6

Finish tapping and verify

Continue until the full thread depth is achieved. Break off the tap with a gentle twist, if needed, and clean the thread. Test the fit with the mating bolt to confirm clean engagement and correct depth.

Tip: Use a depth stop if your setup supports it to prevent over-tapping.

Got Questions?

What drill size do I use for a 3/8-16 tap?

The exact pilot hole size depends on the material and thread form; consult a tapping drill chart or manufacturer recommendations to pick the correct size. This ensures proper thread engagement and reduces the risk of tap breakage.

For a 3/8-16 tap, pick the pilot hole size from a tapping chart and use lubrication for best results.

Can I use any drill for tapping threads?

No. Use a sharp drill of the correct type for the material, and ensure you maintain perpendicular alignment. A dull bit or wrong type can produce undersized holes or uneven threads.

Use a sharp, appropriate drill and keep it perpendicular to the work for clean threads.

Is lubrication required for tapping?

Yes. Lubrication reduces heat, lowers wear on the tap, and improves thread quality. Use a dedicated tapping fluid or light machine oil.

Yes—use oil to reduce heat and improve thread quality.

What should I do if the tap binds or breaks?

Stop turning, back the tap out gently, re-lubricate, and realign before continuing. For a broken tap, use an appropriate extractor or seek professional help.

If it binds, back out slowly and re-lubricate; for a break, use an extractor.

How can I verify thread quality after tapping?

Test with the mating bolt or use a thread gauge. Check for smooth engagement and full thread depth without slop or binding.

Test the hole with a bolt to confirm clean engagement.

What safety gear should I wear when tapping?

Wear safety glasses and gloves as needed. Keep hands away from rotating parts and use clamps to secure the work.

Wear safety glasses and use clamps to secure the work.

Watch Video

Top Takeaways

- Identify the correct pilot hole using a tapping chart

- Choose the right drill type and keep it sharp

- Lubricate and tap with controlled, progressive turns

- Deburr, verify with a gauge, and test fit

- Refer to manufacturer charts for exact sizes