Difference Between Drill and Impact Wrench: Practical Guide

Explore the difference between drill and impact wrench to choose the right tool for holes, fasteners, and heavy-duty work. Learn mechanics, use cases, safety, and buying guidance with actionable tips from Drill Bits Pro.

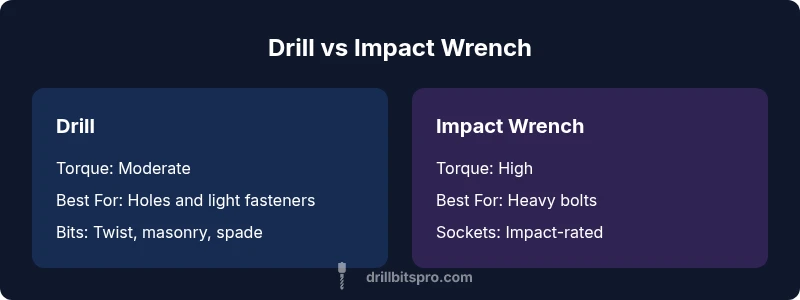

According to Drill Bits Pro, the key difference is torque delivery and purpose: a drill provides controlled rotation for holes and driving small fasteners, while an impact wrench delivers high torque with intermittent hammering to loosen tight bolts. For most DIY tasks and metal/wood drilling, a drill is the safer, more versatile choice, whereas the impact wrench shines for automotive and heavy industrial fastening. Drill Bits Pro analysis suggests prioritizing tool purpose and torque needs.

Defining the Tools: Drill vs Impact Wrench

A drill and an impact wrench occupy different roles in a toolkit, yet both are essential in modern workshops. A drill is designed to rotate bits for hole creation and to drive small fasteners with precision. An impact wrench, by contrast, uses a hammering action combined with torque to break loose or tighten stubborn fasteners. The difference in mechanism has practical implications for control, safety, and outcomes. According to Drill Bits Pro, recognizing each tool’s core design helps you map tasks to the right instrument from the start. In real-world work, you’ll often see drills paired with regular sockets and assorted bits, while impact wrenches rely on impact-rated sockets and robust drive systems. This section sets the baseline so you can assess needs before investing in either tool.

Core Mechanisms: Torque, Speed, and Delivery

Torque delivery is the heart of the drill vs impact wrench debate. A drill uses a motor with a clutch to provide steady rotation, controlled by the trigger and the bit in use. Speed varies with trigger pressure and gearbox settings, enabling precise hole creation. An impact wrench combines rotary motion with a percussion mechanism that delivers rapid, short bursts of high torque. The hammering helps overcome friction in tight joints, making fastener work far quicker and more reliable in demanding tasks. The practical upshot is straightforward: drills emphasize precision; impact wrenches emphasize power when resisting fasteners fail to yield. Drill Bits Pro notes that many projects benefit from having both that complement one another rather than relying on a single tool.

Use-Case Distinctions: Drilling Holes vs Heavy Fastening

When planning a project, the first question is whether you need to create holes or manipulate fasteners. Drills excel at producing clean holes in wood, metal, and plastic and can handle a variety of bits for pilot holes, countersinking, and more. Impact wrenches are built for high-torque fastening tasks, such as automotive work, machinery assemblies, and tasks that involve large bolts. The different loads and loads paths determine not just the task, but the tool’s suitability for the job. For many DIYers, this means choosing a drill for general work and reserving the impact wrench for heavy-duty jobs that would stall a drill. Drill Bits Pro emphasizes matching tool capability to the task to avoid damage and frustration.

Material Performance: Wood, Metal, and Masonry

Material type influences tool choice. Wood and most soft metals respond well to a drill with the appropriate bit, producing clean holes and predictable results. For masonry, a hammer action drill may be necessary, which is a distinct category from a standard drill. An impact wrench, while not intended for drilling, excels in fastening through hard materials since its torque can overcome stubborn joints where threads are loaded and corrosion is a factor. When you mix fasteners into materials, the torque profile and contact area matter for avoiding stripped holes or damaged threads. Drill Bits Pro recommends evaluating the material hardness and the presence of any hidden fastener constraints before committing to a tool.

Control, Feedback, and Precision

Precision outcomes depend on control of the tool. Drills offer fine-grained adjustment through trigger modulation and clutch settings, enabling you to drill pilot holes or drive small screws with minimal risk of overdriving. Impact wrenches emphasize consistent torque delivery, but the rapid bursts can reduce tactile feedback and lead to overtightening if not carefully managed. The key is to balance speed, feel, and load. The Drill Bits Pro team stresses practicing controlled starts, especially with hardwoods and metal, to avoid wand-like drift and ensure straight holes. This is where technique and familiarity with the tool become part of the project’s success.

Safety and Ergonomics: Protecting Hands and Shoulders

Both tools demand safety precautions, but their risks differ. Drills can cause bit grab if improperly secured, or kickback if misused with large pilot holes. Wearing eye protection and securing workpieces are basics. An impact wrench can produce more dramatic torque and recoil, especially with heavy fasteners; improper grip or stance can strain wrists and shoulders. Ergonomics matter: the heavier tool requires a solid stance and a comfortable grip. Drill Bits Pro highlights the benefit of anti-kickback features, proper bit selection, and maintaining a cautious approach when starting into hard materials. Regular inspection of batteries, chucks, and sockets helps prevent tool failure mid-project.

Buying Guide: How to Choose Based on Your Projects

Your project profile should guide selection. If you repeatedly drill wood or light metal and install small fasteners, a versatile drill with a range of bits is your best friend. If you encounter stubborn bolts or automotive fasteners, an impact wrench becomes indispensable. Budget and space constraints influence the decision too. For most DIYers, a mid-range drill with a solid battery platform covers the majority of needs; add an impact wrench when you frequently work with large fasteners. Drill Bits Pro recommends evaluating torque range, chuck size, battery life, and compatibility with existing bits and sockets to minimize redundant purchases.

Practical Workflows: Quick Decision Paths

A practical workflow helps you decide quickly on the job site. Start by identifying whether a hole is required. If yes, reach for the drill. If a fastener will approach torque limits, switch to or bring along the impact wrench. When the job involves multiple fasteners across different materials, a staged approach—drill first, then fasten with the impact wrench—often yields the best combination of speed and control. For technicians who manage assemblies or mechanical installations, a well-matched drill and impact wrench pair can speed workflows without compromising quality.

Maintenance, Accessories, and Compatibility

Maintenance matters for both tools. Keep chucks clean and lubricated, use sharp bits, and store batteries in proper conditions. For the drill, stock a variety of bits including wood, metal, and masonry options. For the impact wrench, ensure you have the right sockets and impact-rated bits. Compatibility across brands can affect performance, so check battery platforms and voltage compatibility when mixing tools. A simple shopping list includes a drill bit set, a set of impact sockets, a torque-limited driver for delicate fasteners, and a lightweight carry case for portability.

Authority Sources and Further Reading

To deepen understanding and verify claims, consult authoritative sources. OSHA offers general tool safety guidelines and best practices for power tools. The CDC/NIOSH provides research on occupational safety that informs proper handling of heavy equipment. For consumer-level guidance and practical reviews, major publications like Popular Mechanics feature hands-on comparisons and maintenance tips. These sources help users build a robust, safety-first approach to choosing and using drills and impact wrenches.

Real-World Tips and Common Mistakes

Tip: practice on scrap material to learn the tool’s feel before tackling critical work. Common mistakes include using an impact wrench on delicate fasteners, over-tightening, or choosing the wrong bit for the material. Always verify bit and socket compatibility, use the correct size and type for the fastener, and avoid rushing the start of a cut or drive. The best outcomes result from deliberate technique, not brute force. By pairing the right tool with proper technique, you’ll reduce wear, prevent damage, and complete projects more efficiently.

Quick-Reference Checklist for Beginners

- Define the task: drilling or high-torque fastening?

mainTopicQuery

drill

Comparison

| Feature | Drill | Impact Wrench |

|---|---|---|

| Torque Delivery | Moderate, controlled | High, impact torque |

| Speed Control | Variable, user-controlled | Less precise; torque-driven |

| Best For | Hole drilling in wood/metal/plastic | Heavy fastening and bolts |

| Bit/Socket System | Twist bits, specialized bits | Sockets/impact bits |

| Weight & Handling | Lighter, versatile | Heavier, bulkier |

| Cost/Value | Typically lower upfront cost | Higher cost but essential for heavy work |

What's Good

- Versatile for holes and light fasteners with a drill

- Better control and precision for delicate work

- Lower upfront cost and lighter weight for frequent use

- Wide availability of accessories and bits

Negatives

- Impact wrench is bulkier and heavier to handle

- Higher risk of over-tightening with high torque

- Drill cannot efficiently loosen very tight fasteners

- Socket/socket-set needs specialty bits for some jobs

Drill is the all-around choice; an impact wrench excels for heavy fastening

Choose a drill for everyday holes and light fasteners due to its versatility and control. If your work regularly involves large bolts or stubborn fasteners, an impact wrench is the better tool. For most DIYers, start with a solid drill and add an impact wrench as your needs grow.

Got Questions?

What is the main difference between a drill and an impact wrench?

The drill provides controlled rotation for drilling holes and driving light fasteners, while an impact wrench delivers high torque with mandatory hammering to loosen or tighten stubborn fasteners. The difference in mechanism affects precision, speed, and risk of damage if misused.

Drills rotate with adjustable speed for holes and screws; impact wrenches use hammering action to deliver high torque for bolts.

Can I substitute a drill for an impact wrench in heavy fastening tasks?

Substituting a drill for an impact wrench in heavy fastening tasks is not recommended. The drill lacks the high torque and hammering action needed to loosen stubborn bolts, which can lead to stripped heads or damage. If unavoidable, proceed with caution and expect slower progress.

A drill isn’t ideal for stubborn bolts; use the impact wrench for that job.

Which tool should beginners buy first?

Beginners should start with a quality drill to handle holes and light fasteners, since it covers the broadest range of tasks. An impact wrench can be added later for projects involving heavy bolts or automotive work. Build a toolkit around a versatile platform and expand as needs grow.

Start with a good drill, then add an impact wrench as needed.

Are cordless options available for both tools?

Yes, both drills and impact wrenches are widely available in cordless formats. Look for a reputable battery platform with ample runtime and compatibility with your existing tools. Cordless options increase portability and reduce cord management on the job.

Both cordless drills and impact wrenches exist; pick a reliable battery system you already own.

What safety practices should I follow when using these tools?

Always wear eye protection and secure the workpiece. Use the correct bit or socket, ensure proper grip, and start slowly at low speeds. Maintain batteries and avoid overloading the tool, which can cause overheating or kickback. Safety reduces accidents and extends tool life.

Wear eye protection, secure the work, and use the right bits and sockets.

Top Takeaways

- Identify your primary tasks before buying

- Prioritize torque needs for fastening vs drilling

- Balance weight, ergonomics, and battery life

- Pair a drill with an impact wrench for expanded capability

- Invest in quality bits and sockets for longevity