Drill vs Impact Driver for Home Use: A Practical Comparison

A detailed, task-focused comparison of drill and impact driver for home use, covering performance, ergonomics, cost, and how to build a practical two-tool kit for DIY and professional projects.

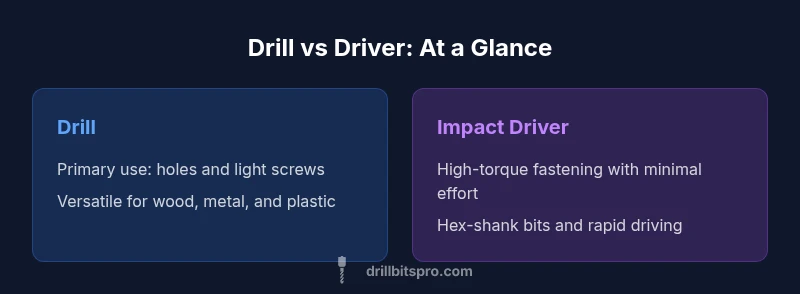

When deciding between a drill or impact driver for home use, remember: drills handle precision drilling and light screw driving, while impact drivers excel at driving larger fasteners with less effort. According to Drill Bits Pro, the best choice depends on your typical tasks and budget, favoring a versatile base drill plus occasional impact driver for most DIYers.

Choosing between drill or impact driver for home use

Deciding between a drill and an impact driver starts with your typical projects. A drill provides precise control for bore holes and light screw driving, making it a true all-rounder for wood, metal, and plastic. An impact driver, by contrast, delivers high torque in short bursts that dramatically reduce the effort required to drive long or coarse-threaded screws. The Drill Bits Pro team emphasizes task-first thinking: if you mainly drill holes and occasionally fasten small screws, a good drill may cover most needs; if fastening large fasteners is common, an impact driver shines. For many DIYers, the optimal setup is a compact, capable drill paired with an occasional impact driver. This two-tool approach offers flexibility without overcommitting to one specialized device. In this guide, we’ll explore how these tools behave in real-world home scenarios, and how to avoid common buying mistakes that leave you with gaps in capability. According to Drill Bits Pro, prioritize task alignment and scalable value over chasing the latest gadget.

Core mechanics and why they matter

Understanding the fundamental mechanics helps you predict how a tool will perform on your projects. A drill relies on a steady rotary action to cut holes and drive screws with controlled torque. It typically uses a chuck to hold various drill bits and screwdriver bits, enabling quick changes between tasks. An impact driver, on the other hand, uses a rotational hammer mechanism to deliver short, powerful bursts that convert torque into driving force. The result is high-impact fastener driving with less muscle fatigue, especially on hardwoods or dense materials. For home users, the practical takeaway is clear: if a job requires drilling and precision screwing, start with a drill; if your goal is fast, heavy-duty fastening, an impact driver should be your go-to option. Drill Bits Pro analysis shows that matching tool action to task reduces user fatigue and improves accuracy in repetitive work, which is a practical win for any DIY project.

When a drill shines: common home projects

Drills excel in a wide range of tasks you’ll encounter around the house. For precise hole placement, tapping pilot holes, and light screw driving, a drill offers superior control and versatility. You’ll find drilling jobs in furniture assembly, cabinet installation, shelf mounting, and fixtures where hole diameter and depth matter for a clean fit. In soft woods, drills handle rapid assembly pleasantly, while metal drilling benefits from a steadier hand and adjustable speed control. For those on a budget or space-limited shop, a compact drill can handle most everyday tasks, especially when paired with a handful of high-quality bits and a selection of screwdriver bits. The key is to choose a model with a comfortable grip, reliable speed control, and compatibility with common bit interfaces. By selecting a drill that balances weight and ergonomics, you’ll reduce strain during longer sessions and preserve accuracy across projects.

When an impact driver shines: heavy fasteners and quick work

Impact drivers are designed to handle tough fastening scenarios with minimal effort. When you’re driving long or coarse-thread screws, lag bolts, or deck-fastening hardware, the impact action dramatically reduces spinout and cam-out. This makes tasks like building a deck frame, fastening cabinetry, or securing dense materials much easier on your wrists. For home users, the impact driver’s ergonomic advantage is clear: you can reach higher torque without using excessive grip strength. However, impact drivers are not substitutes for drilling holes; without appropriate drill bits, you’ll struggle to bore into wood or metal. A practical approach is to reserve the impact driver for driving and fastening tasks while using the drill for holes and precision screw work. This division of labor minimizes tool-switching and maximizes efficiency on common home projects.

Bits, attachments, and compatibility: what to buy first

Bit compatibility often drives initial satisfaction with a drill or impact driver. Drills use standard chucks that accept a wide array of drill bits and screwdriver bits with hex shanks or star/torx patterns. Impact drivers typically require hex-shank bits, which are highly durable under high-torque action. When planning your kit, consider purchasing a small set of drill bits in common sizes for wood and metal, a handful of driver bits that fit your chosen screw types, and a handful of hex-shank bits for the impact driver. Some models offer rapid bit changes and reversible chucks, which can speed up workflows in cramped spaces. Another practical tip is to keep a universal bit set that covers the most frequent tasks you face, from cabinetry to basic metalwork. By focusing on core bits first, you’ll unlock the practical benefits of each tool sooner and minimize wasted purchases later.

Ergonomics and comfort for longer sessions

Long sessions demand comfortable handling and balanced weight distribution. Drills tend to be more forgiving in ergonomic design because they are built for both drilling and screw driving, but some models can feel top-heavy when loaded with heavy bits. Impact drivers, while compact in some models, deliver high torque bursts that can be taxing if you’re not used to them. If your workshop involves extended fastening tasks, prioritize models with rubberized grips, well-placed trigger access, and a low center of gravity. A good grip helps you maintain control and reduce fatigue. In addition, check for low-vibration features and a sound level you can live with, especially when working indoors. Investing in a comfortable, balanced tool reduces the risk of repetitive strain injuries and enhances precision across projects.

Battery platforms, chargers, and long-term value

Cordless tools offer the convenience of portability and a growing ecosystem of batteries and chargers. A common pitfall is choosing tools without considering battery compatibility. If you’re leaning toward a two-tool setup, ensure both devices use a common battery platform to maximize runtime and simplify charging. From a value perspective, shared batteries reduce ownership costs and simplify maintenance. When evaluating models, consider the availability of spare batteries, rapid chargers, and the ease of finding replacement parts. A steady battery platform can make a big difference in how efficiently you can complete tasks, especially during busy weekends with back-to-back projects. The Drill Bits Pro team notes that choosing a compatible system often yields better long-term value than chasing the latest single-tool feature.

Building a practical home toolkit: a two-tool plan that fits most homes

For most homeowners, the most practical path is a two-tool kit: a reliable drill for precision work and a capable impact driver for fasteners. This combination covers the majority of DIY tasks, from mounting shelves and assembling furniture to drilling holes in wood and metal. When selecting, you should evaluate your typical project mix, the space you work in, and your budget. Consider a drill with ergonomic shoulders and a comfortable handle, along with an impact driver that offers a balanced weight and a controllable trigger. If you anticipate frequent heavy fastening or outdoor projects, ensure the impact driver can handle long sessions without overheating. The key is to start with essential capabilities and then expand as needed, rather than buying multiple specialty tools upfront. This approach keeps your shop lean and effective while preserving budget flexibility for future projects.

Common mistakes and maintenance to extend life

Common mistakes include neglecting battery care, ignoring bit compatibility, and failing to maintain a clean, dry storage environment. Regularly inspect the chuck, bits, and fasteners for wear, and replace worn components promptly to prevent reduced performance or damaged materials. Keep the battery contacts clean, avoid exposing tools to excessive moisture, and store them in a dry space. Cleaning the vents and checking for overheating signs after long usage helps prevent performance drops. When not in use, remove batteries to avoid self-discharge and store at an appropriate temperature. A simple maintenance routine pays off by preserving performance and extending the life of both tools so you can rely on them for many projects.

Comparison

| Feature | Drill | Impact Driver |

|---|---|---|

| Primary use | Hole drilling and light screw driving | Heavy fastener driving with high torque |

| Drive mechanism | Rotary drill chuck with variable bits | Rotational hammering with hex-shank bits |

| Torque control | Fine torque settings and speed control | High-torque bursts with rapid driving |

| Best for | Woodworking, metal drilling, light fastening | Long screws, lag bolts, dense materials |

| Size/ergonomics | Balanced for drilling and overhead work | Compact and easy one-handed use in tight spaces |

| Typical cost range | Entry-level to mid-range configurations | Mid-range to premium for strong torque and durability |

What's Good

- Versatile across drilling and fastening tasks

- Torque settings improve control for delicate work

- Wide availability and spare parts

- Opportunity to build a two-tool kit for flexibility

Negatives

- Two tools may be needed for optimal coverage

- Higher upfront cost compared to a single tool

- Battery management becomes a consideration with two devices

Two tools strike the best balance for most home projects.

A drill handles holes and light screws well, while an impact driver speeds up heavy fastening. For most DIYers, starting with a solid drill and adding an impact driver later delivers versatility and long-term value.

Got Questions?

What is the main difference between a drill and an impact driver?

A drill provides steady rotary motion for drilling holes and light screw driving, while an impact driver delivers high-torque bursts for fasteners, reducing effort and cam-out. The two tools excel in different tasks, making a two-tool setup often the most versatile choice.

A drill is for drilling and light screws, an impact driver is for heavy fastening with less effort.

Can I drill holes with an impact driver?

Impact drivers are not designed primarily for drilling holes. They can accommodate some hex-shank drill bits in limited cases, but for clean holes and precision, a drill is the better choice.

Impact drivers focus on fastening; use a drill for holes.

Should I buy one tool or two?

If your budget allows, two tools offer the most flexibility for home projects. If you must start with one, choose a compact drill with bit options, and add an impact driver as your needs grow.

Two tools give you the most versatility; start with a drill and add an impact driver later.

What features should I prioritize when buying?

Prioritize torque range, ergonomic grip, battery platform compatibility, and chuck quality for the drill; for the impact driver, look for a strong driver system, comfortable trigger, and compatibility with a variety of hex bits.

Focus on torque, comfort, and battery compatibility.

Are cordless tools worth it for beginners?

Cordless tools are highly practical for beginners due to portability and ease of use. Establish a single battery platform to simplify charging and maintenance, and choose models with good support and replacements.

Yes, cordless tools are ideal for beginners; pick a single battery system.

Top Takeaways

- Assess your project mix to decide between drill and driver

- Prefer a two-tool setup for the broadest home coverage

- Choose ergonomic designs with compatible battery platforms

- Invest in core bits and driver bits first for immediate usefulness

- Maintain tools and batteries for longevity