How to Change the Tip of a Drill: A Practical Guide

Learn how to change the tip of a drill safely with a step-by-step approach. Find tips on selecting the right bit, removing the old tip, installing a new one, and testing seating for cleaner holes and longer tool life.

Power down your drill and gather the right tip before you begin. In this steps-based guide, you’ll learn how to change the tip of a drill safely and correctly. You’ll select the correct bit, remove the worn tip, install a fresh one, and test seating. Expect clear instructions, safety reminders, and practical tips for DIYers and professionals.

Preparation and safety for changing the drill tip

According to Drill Bits Pro, safety and methodical prep are the foundation of a successful tip change. In this module, we outline the essential steps you should take before touching the chuck: unplug the drill, secure the workpiece, and select the correct tip size for your intended material. The goal is to minimize chatter, prevent bit snag, and protect both the drill and your hands. Start by inspecting your drill to ensure the chuck operates smoothly and that there are no cracks in the housing. Gather the necessary tools and a clean workspace. By planning your change, you reduce risk and extend tool life. When you approach this task, remember that each step builds on the previous one and that careful preparation pays off with cleaner holes and less wear on the drill.

Choosing the right tip for your drill and material

Different materials and drilling tasks demand different tips. For metal and hardwood, twist drills are common; for masonry you typically need a carbide or diamond-coated bit; for plastic, spade or auger bits may work best. Before selecting a new tip, verify the shank size matches your drill's chuck (for cordless drills, a standard 1/4 inch or 6 mm shank is common). Always consider flute length and helix angle, because these influence chip removal and heat. Drill Bits Pro emphasizes matching tip geometry to the job to reduce wear and improve hole quality.

Safety and workspace setup

Create a clean, well-lit work area with a sturdy vise or clamp for securing the workpiece. Wear safety glasses, hearing protection if needed, and gloves if handling hot or sharp bits. Ensure the drill is unplugged or the battery removed before any tip handling. Keep loose clothing away from spinning parts and remove jewelry. If you are using a corded drill in a wet environment, unplug the power source and dry the area first. A stable setup reduces the risk of slips and accidental slips.

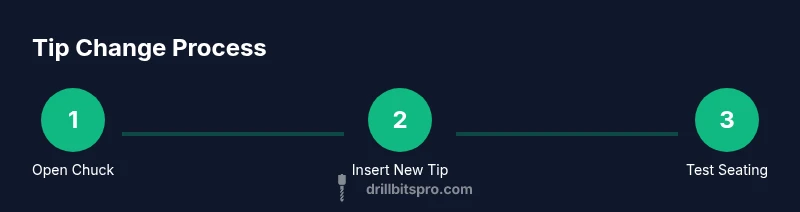

Step-by-step overview for replacing a drill tip

This section provides the high-level flow you will follow: unplug the drill, open the chuck, remove the old tip, inspect and clean the shank, select and insert the new tip, seat it securely, and run a test on scrap material. Following this order minimizes tool damage and ensures consistent hole quality. The steps below are designed to be performed in sequence without skipping any action.

Common causes of tip wear and how to prevent

Excessive feed rate, insufficient lubrication, and drilling into hard materials without proper tip type accelerate wear. Dull, chipped, or rusted tips also perform poorly and can cause wandering holes. Prevention includes using the correct tip for the material, applying light lubrication for metal drilling, and letting the drill do the work rather than forcing it. Inspect tips regularly and replace worn bits promptly to avoid dragging dull edges through your work.

Special cases: keyed chucks vs. keyless chucks

If your drill uses a keyed chuck, you will need the chuck key to tighten or loosen when removing or inserting tips. For keyless chucks, you can usually open the jaws by hand or with a denser grip if needed. Always confirm that the chuck is fully open before attempting to extract a tip. After inserting the new tip, run the chuck to ensure it seats squarely and spins true.

How to inspect seating and test the new tip

Proper seating means the tip is fully engaged in the chuck and aligned with the drill axis. Spin the bit by hand briefly to check for wobble, then clamp a scrap piece and perform a shallow drill to feel for smooth cutting and consistent chip formation. If the bit wobbles or binds, reseat it and tighten further. Never continue drilling with a poorly seated tip; this can cause damage or injury.

Maintenance after changing tips

Clean the shank and chuck jaws after removal and installation to remove dust and debris. Store tips in a labeled case to prevent loss and mix-ups. Regularly inspect the chuck for wear and replace it if teeth are rounded or stiff. Keeping a tidy workspace and updating your tools list helps reduce downtime in future projects.

AUTHORITY SOURCES

- https://www.osha.gov

- https://www.cdc.gov/niosh/topics/ppe/default.html

- https://www.cdc.gov/niosh/index.htm

Tools & Materials

- Drill bit tip (correct type and size)(Select for material and shank size)

- Chuck key or hex wrench (if required)(Needed to open/close chuck.)

- Safety glasses(Eye protection)

- Clean rag or brush(For cleaning shank and chuck)

- Lubricant or cutting oil (optional)(Help with metal drilling)

- Clamp or vise (optional)(Hold the workpiece securely)

Steps

Estimated time: 15-25 minutes

- 1

Power down and secure the workspace

Unplug the drill from power or remove the battery. Place it on a stable surface and clamp the workpiece to prevent movement during the tip change. This reduces the risk of slips and injury while you work.

Tip: Always disconnect power before handling the chuck. - 2

Open the chuck to release the old tip

Use the chuck to open as wide as possible. If you have a keyed chuck, insert the key and turn counterclockwise to loosen; for keyless chucks, grip the jaws firmly and twist to open.

Tip: Ensure the chuck is fully open to avoid pinching fingers. - 3

Remove the old tip

Gently pull the old tip straight out from the chuck once the jaws are fully open. If it resists, a small twist while pulling can help. Do not hammer or force the bit, as this can damage the chuck.

Tip: Never strike the bit with metal objects. - 4

Clean and inspect the shank and chuck

Wipe the shank with a clean rag to remove dust and debris. Check for burrs, rust, or wear on the chuck jaws. If you notice damage, address it before installing a new tip.

Tip: Burrs can cause misalignment and poor seating. - 5

Select and verify the new tip

Choose a tip that matches the material and shank size. Compare flute length, helix, and tip angle to your prior bit to ensure similar performance. Verify compatibility with your drill model.

Tip: Cross-check the new tip against the old one before installation. - 6

Insert the new tip and seat securely

Place the new tip into the chuck and tighten the jaws evenly. Ensure the tip is square to the drill axis and seated firmly without wobble.

Tip: Tighten gradually and test fit by spinning the chuck briefly. - 7

Test seating with a dry run

Spin the bit by hand to ensure it runs true. If there is any wobble, reseat and tighten again. A proper seating minimizes vibration and drill wear.

Tip: If wobble persists, stop and recheck alignment. - 8

Perform a drill test on scrap material

Drill a shallow hole in a scrap piece to verify cutting performance and hole quality. Watch for smooth chips and consistent depth. If issues arise, stop and readjust seating or choose a different tip.

Tip: Observing heat buildup helps determine if lubrication is needed. - 9

Cleanup and storage

Wipe down the chuck area and store the tip in a labeled case to prevent loss. Return the drill to service only after the tip seating test passes.

Tip: Keep a tidy toolkit to reduce downtime in future projects.

Got Questions?

Can I change a drill tip without removing the chuck?

No. Accessing and replacing the tip typically requires opening the chuck and removing the current bit. Removing the tip ensures a clean seat and reduces the risk of jamming or misalignment.

You generally need to open the chuck and take out the old tip to replace it safely.

What size should the new tip be?

Choose a tip that matches your drill’s chuck size and the material you’re drilling. Mismatched shanks or wrong flute geometry can cause poor cutting and premature wear.

Make sure the tip’s shank fits your chuck and that it’s suited for the material.

Is it safe to change tips with the drill plugged in?

Never change tips with power connected. Unplug the drill or remove the battery before handling the chuck to prevent accidental starts.

Always disconnect power before touching the chuck.

Can I use any drill tip with a cordless drill?

Cordless drills can use most standard tips, but verify the chuck size and the bit’s shank compatibility. Some drills have smaller chucks that require shorter or thinner shanks.

Check the chuck size and tip shank before using.

How do I know when a tip needs replacement?

Replace tips when they show dull edges, visible chips, bending, or reduced hole quality. Worn tips increase heat and can ruin material.

Look for dull edges or chips as signs to replace the tip.

Should I lubricate the tip when drilling metal?

A light application of cutting oil or lubricant can reduce heat and extend tip life when drilling metal. Avoid excess lubrication that can smear chips.

A small amount of oil helps, but don’t overdo it.

Watch Video

Top Takeaways

- Always unplug before handling the chuck

- Verify tip compatibility before installation

- Seat the new tip square to avoid wobble

- Test on scrap material before regular use

- Maintain a clean workstation to extend tool life