How to Drill a Pilot Hole: Practical Step-by-Step Guide

Master drilling a pilot hole safely. This Drill Bits Pro guide covers marking, centering, securing, drilling straight, deburring, and testing for precise fastener placement.

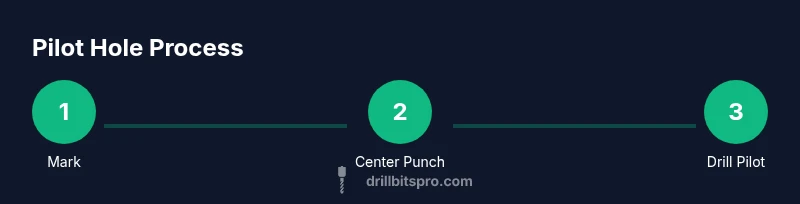

You will learn how to drill a pilot hole safely and accurately. You will need a drill, appropriate drill bit size, a center punch, tape, and clamps. Follow these steps in order: mark, center punch, drill pilot, deburr, and test fit. According to Drill Bits Pro, using a sharp bit and steady speed reduces wandering.

Why pilot holes matter

A pilot hole is a small-diameter hole drilled before the final hole or screw. It helps guide the drill, reduces material splitting, and prevents the bit from wandering. According to Drill Bits Pro, starting with a pilot hole is essential when working with hardwoods, brittle materials, or dense metals because it directs the fastener along the intended path and lowers the risk of thread tearing. In wood, a proper pilot hole can reduce tear-out at entry and improve screw holding power. In metal, it improves alignment and reduces heat buildup. Before you start, inspect the workpiece for knots, grain direction, and existing defects; plan your hole location with care and consider guard rails or clamps to hold the piece steady. This preparation minimizes rework and ensures a cleaner finished product. If you’re drilling on a finish surface, place painter’s tape over the mark to prevent chipping and provide a clean entry.

Choosing the right drill bit and size

The key to a clean pilot hole is selecting the right bit and diameter for your material and screw. Wood typically benefits from a center-guided bit (brad point) or a sharp twist bit that matches the wood grain. For metal, a sharp twist bit designed for metal is preferred. In all cases, start with a small pilot size and widen gradually if the screw or final hole requires it. Avoid using a bit that is too large, which can split the material or misalign the screw, or a bit that is too small, which creates excess friction and brittle edges. When in doubt, test your approach on a scrap piece and choose the method that yields a clean entry and snug fit. For thick stock, use a longer bit and a slow feed to prevent deflection.

Tools and safety setup

Prepare a drill with variable speed, sharpened bits, a center punch, masking tape, clamps, a square or ruler for alignment, and safety gear. Clamps hold the workpiece securely to prevent movement. Tape can help prevent the bit from wandering on smooth surfaces. Center punch marks the exact spot to reduce drift. Safety goggles and hearing protection protect your eyes and ears from chips and noise. A scrap piece underneath the workpiece is recommended to catch shavings and provide stable backing for drilling. Keep a small container handy to collect chips and avoid slipping.

Practical drilling technique

Begin with the center punch mark, then secure the workpiece. Choose the pilot bit and start drilling at a slow speed with light pressure, keeping the bit perpendicular to the surface. Feed gradually and allow the bit to cut; back the bit out occasionally to clear chips. If drilling through metal, use cutting oil to reduce heat and wear. For wood, maintain steady pressure and avoid forcing the drill, which can cause the bit to skate or wander. If you encounter resistance, back out and re-align rather than forcing the bit.

Deburring and testing fit

After drilling, remove the bit, deburr any rough edges with a knife or deburring tool, and test-fit the screw or final hole. If the screw binds, widen the pilot slightly using the next size up and re-try. If the hole is too loose, you may recenter and re-drill with a slightly larger bit or tap the hole for threads if applicable. Finally, drive a test screw in a scrap piece to confirm alignment before proceeding on the workpiece.

Tools & Materials

- Drill (corded or cordless)(Ensure chuck accepts your pilot bit and battery is charged)

- Correct drill bit(Brad point for wood; twist bit for metal; sharp and appropriate length)

- Center punch(Creates a precise indentation to guide the drill)

- Clamp or vise grip(Secure the workpiece firmly to prevent movement)

- Masking tape(Helps prevent bit wander and protects surface)

- Marker or pencil(Mark the exact drill point)

- Safety goggles(Protect eyes from chips)

- Optional cutting oil(Useful for metal to reduce heat)

Steps

Estimated time: 20-35 minutes

- 1

Mark the drill point

Use the marker to pinpoint the exact location. Gently press the center punch to create a small indentation that guides the bit. This reduces wandering when you begin drilling.

Tip: Double-check alignment with a square or ruler before punching. - 2

Secure the workpiece

Clamp the piece firmly to a stable surface. Ensure there is no movement when you apply pressure with the drill. A secure setup prevents mishaps and keeps the hole straight.

Tip: Place a scrap underneath to support defeats and chips. - 3

Select bit and prepare pilot size

Choose a bit appropriate for the material and the intended final hole. Start with a noticeably smaller pilot size than the final requirement and have a plan to progress to the final size if needed.

Tip: Test the chosen bit on scrap material first. - 4

Drill the pilot hole

Position the drill perpendicularly to the surface and start at a slow speed with light pressure. Allow the bit to cut gradually; avoid pushing too hard or twisting the bit. Withdraw the bit occasionally to clear chips.

Tip: Keep hands away from the chuck and maintain a straight line with the hole. - 5

Clear chips and deburr

Withdraw the bit, then clean out chips from the hole. Lightly deburr the entry edge to smooth the surface and prevent snagging when you drive a fastener.

Tip: Use a deburring tool or a sharp knife for clean edges. - 6

Test fit and finalize

Insert the final screw or the intended fastener to check fit. If resistance occurs, adjust by stepping up to the next pilot size and re-testing. Confirm that the final hole meets the required alignment and depth.

Tip: Always test on a scrap piece first if possible.

Got Questions?

What is a pilot hole and why is it important?

A pilot hole is a small-diameter hole that guides the final screw. It helps prevent material splitting, reduces wandering, and improves alignment and holding power.

A pilot hole guides the screw, prevents splitting, and keeps the screw aligned for a stronger hold.

How do I choose the right pilot hole size?

Choose the hole size based on the screw diameter and material. Start with a smaller pilot and gradually increase it while testing fit.

Start with a small pilot and increase until the screw fits cleanly.

Can I drill pilot holes in metal and wood the same way?

Both can use pilot holes, but metal requires bits and speeds suited for metal, plus cooling oil for heat management. Wood often tolerates brad-point or sharp twist bits.

Yes, but use metal-specific bits and lubrication for metal; wood uses wood-specific bits.

What safety gear should I wear when drilling?

Wear safety glasses and hearing protection. Secure the workpiece and keep fingers away from the drill path.

Goggles and ear protection are essential; secure the piece before starting.

Why does my drill wander during drilling?

Wandering often results from marking drift, dull bits, or an unsecured workpiece. Center-punching and clamping help eliminate drift.

Drill wanders due to drift, dull bits, or movement; center-punch and clamp to fix.

Watch Video

Top Takeaways

- Mark the exact spot before drilling.

- Secure the workpiece firmly with clamps.

- Start with a small pilot hole and progress gradually.

- Drill straight with steady, moderate pressure.

- Deburr and test fit for best results.