How to Drill into a Wall: A Practical Step-by-Step Guide

Learn how to drill into a wall safely and effectively. This step-by-step guide covers drywall and masonry, tool choices, anchors, stud-finding, and safety tips for DIY enthusiasts and professionals.

With this guide, you'll learn how to drill into a wall safely and effectively. You'll choose the right drill bit for drywall or masonry, locate studs or use appropriate anchors, drill pilot holes, advance steadily, and secure fixtures without damaging wiring or pipes. We'll cover safety gear, step-by-step actions, and common mistakes to avoid.

Understanding wall materials and drilling basics

Understanding what lies behind your wall is the first line of defense when you learn how to drill into a wall. Residential walls can be drywall over studs, plaster over lath, or masonry like brick or concrete. Each type requires a slightly different approach, bit, and drilling technique. Drilling into drywall is usually straightforward, but you must avoid wires, pipes, and hidden components. The Drill Bits Pro team emphasizes safety and precision: plan your hole, select the correct bit, and use the right anchors for the fixture. For masonry or brick, you need a hammer drill and a carbide-tipped masonry bit designed to cut through hard surfaces. In this guide, we’ll walk through drywall and masonry scenarios, plus practical safety steps to protect you while drilling. By the end, you’ll be able to tackle common wall holes for shelves, picture frames, and fixtures with confidence.

Selecting the right drill bit and drill type

Choosing the correct drill bit and drill type is the core decision that determines whether your hole stays true and your fixture stays secure. Drywall and plaster walls typically require sharp twist bits in small pilot-hole sizes (often 1/8" to 3/16" for light anchors). Masonry walls require carbide-tipped masonry bits with a hammer drill or the hammer function on your drill to break through brick or concrete. For locating studs, always start with a stud finder and confirm with tapping or a magnet test. If you’ll anchor into a stud, you may be able to use a standard screw; if you’re anchoring into masonry or hollow walls, you’ll switch to plastic expansion anchors or toggle bolts. Remember: the drill’s speed and pressure should be adjusted to the material—fast in soft drywall, slower and steadier for masonry.

Preparing your workspace and safety gear

A tidy, well-lit workspace reduces mistakes when drilling into walls. Clear the area, remove obstacles, and lay down a drop cloth to catch dust. Wear safety glasses to protect your eyes from debris, a dust mask to avoid inhaling fine particles, and gloves if you’ll handle sharp tools. Keep long hair and loose clothing away from the drill and cord. If you’re drilling for a fixture at height, use a stable step ladder and have a helper nearby. Ventilate the space to minimize dust buildup, and keep a vacuum or brush handy to capture dust as you work. By prioritizing safety and cleanliness, you’ll avoid injuries and finish faster with cleaner results.

Locating the studs and avoiding utilities

Locating studs is essential for secure mounting, but you must also avoid hidden utilities. Start with a stud finder to locate vertical framing members, then confirm with light tapping or a tape measure to identify stud centers. Mark your planned hole with a light pencil mark. Before drilling, check for visible electrical outlets, wires, or plumbing in the wall cavity. If you’re unsure, turn off the circuit at the breaker that runs through that area, and consider using a non-contact voltage tester. If you’re mounting a heavy fixture, try to hit a stud for maximum support; otherwise, use appropriate anchors that hold in drywall or masonry. This careful planning reduces the risk of wall damage and ensures a secure installation.

Drilling technique for drywall and stud walls

When drilling into drywall, keep the bit perpendicular to the wall and use a light, steady pressure. Start with a small pilot hole to guide larger bits, then increase only as needed for your anchor. For hollow walls, use wall anchors designed for drywall and install them according to the manufacturer’s instructions. If your wall includes a stud, you can drive screws directly into the wood, which provides stronger support. In all cases, avoid pushing too hard; let the bit do the work to prevent tearing or wandering. Keep the drill at a consistent speed and back the bit out occasionally to clear debris.

Drilling into masonry (brick/concrete) walls

Masonry drilling requires a carbide-tipped bit and either a hammer drill or a drill with a hammer function. Begin with a small pilot hole to reduce bit wandering, then enlarge to the final hole size required by your anchor. Use a slow, steady feed and avoid overheating the bit by pausing briefly if it becomes dull or white-hot. Keep the drill perpendicular to the wall to prevent an angled hole that compromises anchor strength. Apply light moisture to the surface if the environment allows; this can reduce dust, but confirm manufacturer guidance first. After drilling, remove dust from the hole to ensure proper anchor seating and strength.

Installing anchors, screws, and fixtures

Anchors are critical when mounting fixtures into drywall or masonry. For lightweight loads, plastic expansion anchors are usually sufficient; insert the anchor until it sits flush, then screw in the fixture. For heavier loads, use metal toggle bolts or masonry anchors with larger holes. After inserting the anchor, gently pre-drive the screw to check seating, then tighten until secure but not over-torqued. In masonry, ensure the anchor is the correct type for brick or concrete and match its diameter to your screw for a clean fit. Always re-check alignment after installation and use a level to ensure the fixture sits squarely.

Common mistakes and troubleshooting

Common errors include wandering holes, overheating bits, and drilling too deep or too shallow. Wander happens when the bit isn’t perpendicular or you apply uneven pressure; fix by stopping, realigning, and starting anew. Overheating dulls bits and can cause poor cuts; let the bit cool and sharpen or replace as needed. Drilling into the wrong surface (e.g., concrete when you only needed drywall) wastes time and tools. If a hole doesn’t accept an anchor, withdraw and select a larger size or different anchor type. If you hit a pipe or wire, stop immediately, evacuate the area, and reassess approach with a professional if needed.

Maintenance and safe cleanup after drilling

After drilling, wipe away dust and debris from the hole and surrounding area. Inspect bits for wear and replace dull bits to maintain clean cuts. Store drill bits dry to prevent rust and keep them organized in a case. Return the drill to a safe spot, disconnect the battery, and tidy your workspace. Regular tool maintenance extends tool life and improves safety for future projects. Finally, document your wall type and hole locations for future reference, especially if you’ll be adding fixtures later.

Authoritative sources and quick references

For safety standards and best practices, consult authoritative sources. OSHA provides general safety guidelines on eye protection and personal protective equipment. University extensions offer practical how-tos for DIY drilling and mounting. See the following resources for additional guidance:

- https://www.osha.gov/

- https://extension.illinois.edu/

- https://extension.psu.edu/

These sources help reinforce proper technique, materials selection, and safety protocols when learning how to drill into a wall. Always prioritize a careful plan, correct tooling, and adherence to local building codes.

Tools & Materials

- Cordless drill or hammer drill(Choose with enough torque; ensure battery is charged or cord is long enough for the job)

- Masonry drill bit (carbide-tipped)(For brick/concrete; use hammer function if available)

- General-purpose twist drill bit (1/8"–3/16")(Drywall and pilot holes; have multiple sizes)

- Stud finder(Prefer with live-wire detection; helps locate studs and avoid pipes)

- Tape measure(For precise hole placement and alignment)

- Pencil or marker(Mark the exact spot and stud centers)

- Level(Ensure fixtures sit square)

- Safety glasses(Protect eyes from debris)

- Dust mask(Reduce inhalation of fine dust)

- Wall anchors (plastic or metal)(Use appropriate anchors for drywall or masonry)

- Screws sized to anchors(Choose length based on fixture weight and wall type)

- Vacuum or dust brush(Clean up dust as you work)

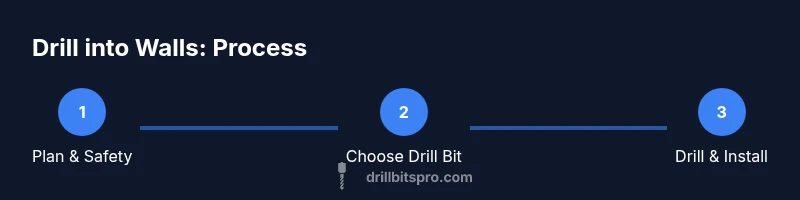

Steps

Estimated time: about 60-90 minutes

- 1

Plan and safety check

Begin by identifying the exact hole location and purpose. Confirm wall type, fixture weight, and whether you’ll hit studs or use anchors. Put on safety glasses and a mask, and clear the area.

Tip: Always mark a pilot hole location first to guide your drill. - 2

Locate studs and utilities

Use a stud finder and, if available, a live-wire tester to map out studs and avoid electrical lines or pipes. Mark the center of the stud to maximize screw strength.

Tip: If unsure, drill a shallow exploratory hole to confirm material. - 3

Choose the drill bit

Select a bit based on wall type: drywall/plaster uses standard twist bits; masonry walls require a carbide-tipped masonry bit with hammer action.

Tip: Keep extra bits on hand for different anchor sizes. - 4

Mark and align your hole

Place your mark precisely and use a level to ensure horizontal alignment. For multiple holes, use a template or level line.

Tip: Double-check alignment before drilling. - 5

Drill the pilot hole

Start with a shallow pilot hole (smaller than final hole) to guide the bit and reduce wandering. In drywall, this prevents tearing; in masonry, it reduces stress on the bit.

Tip: Keep the drill perpendicular and steady. - 6

Enlarge holes as needed

Progressively enlarge the hole to the final size needed by your anchor. Pause to remove debris between enlargements.

Tip: Do not force the bit; let it cut at its own pace. - 7

Install anchors or insert screws

If using anchors, insert them fully and flush. For studs, drive screws directly into wood, ensuring they’re snug but not over-tight.

Tip: Test the anchor by gently tugging to verify seating. - 8

Mount fixture and verify level

Mount the fixture, tighten screws, and check for levelness. Adjust as needed to ensure a clean, secure fit.

Tip: Use a spacer if mounting on irregular surfaces. - 9

Clean up and inspect

Vacuum dust, wipe the area, and inspect the wall for any cracks or damage. Store tools properly for next use.

Tip: Document any wall type notes for future projects. - 10

Final safety and quality check

Ensure all fasteners are secure and the fixture is stable. Recheck for any sharp edges or loose debris before leaving the job site.

Tip: If you’re mounting heavy items, consider professional assessment.

Got Questions?

What is the best drill bit for drywall?

For drywall, use a sharp twist drill bit in a small pilot-hole size (typically 1/8" to 3/16"). If you’re going into studs, a larger pilot hole helps seat screws without splitting the wood. Always drill perpendicular to the surface to prevent wandering.

Drywall needs sharp twist bits for pilot holes; drill perpendicular to the wall and use the right size to avoid cracking.

Can I drill into a wall behind an outlet?

Yes, but first turn off the circuit feeding that outlet and verify there are no live wires. Use a stud finder with wire-detection, and avoid drilling near boxes. If in doubt, consult a licensed electrician.

Turn off power to the outlet, test for live wires, and avoid boxes when drilling.

What anchors work best in hollow walls?

For lightweight loads, plastic expansion anchors work well. For heavier loads, consider metal toggles or masonry anchors appropriate to the wall material. Always match anchor diameter to screw length for secure seating.

Use plastic anchors for light items and toggles for heavier loads; ensure you pick anchors that fit your screw size.

How do I avoid hitting utilities when drilling?

Use a stud finder with live-wire detection and confirm with a non-contact tester if available. Mark the safe drilling zone, and avoid areas near outlets, switches, or obvious plumbing lines.

Use a stud finder with wire detection and test before you drill to avoid wires.

Is a hammer drill required for brick or concrete?

Yes, for brick or concrete a hammer drill or drill with hammer mode is essential. Use a carbide-tipped masonry bit and go slowly to prevent bit wear and surface chipping.

A hammer drill is needed for brick or concrete to cut effectively.

What about cleanup after drilling?

Vacuum the dust, wipe surfaces, and store bits dry. Proper cleanup reduces mess and extends tool life for future projects.

Clean up dust with a vacuum and dry tools for next use.

Watch Video

Top Takeaways

- Plan, locate, and verify wall type before drilling.

- Choose the correct bit and anchors for drywall vs masonry.

- Drill slowly and perpendicular to avoid wandering or breakage.

- Always verify alignment with a level and test anchors for support.